Stop guessing and start cutting right! This guide breaks down every major saw blade material—from HSS to diamond—so you pick the perfect blade for wood, metal, or tile. Learn expert tips to extend blade life and avoid costly mistakes. Get your projects done faster and cleaner.

Key Takeaways

- Match blade material to your project: HSS for softwoods, carbide for hardwoods/metal, diamond for tile/concrete. Using the wrong type ruins cuts and blades.

- Carbide-tipped blades last 10-20x longer than HSS: Worth the investment for frequent woodworking or metal cutting. Look for higher carbide grade numbers (e.g., C3/C4).

- Diamond blades need water for most materials: Dry-cutting concrete or tile causes overheating and rapid wear. Always check manufacturer specs.

- Blade tooth count matters as much as material: Fewer teeth (18-24) for fast rip cuts in wood; more teeth (40-80) for smooth crosscuts. Adjust for metal (finer teeth).

- Proper maintenance doubles blade life: Clean pitch buildup with a brass brush, store blades flat, and never force a cut. A dull blade is dangerous!

- Safety first: Always wear eye protection and hearing gear. Let the blade do the work—forcing it damages teeth and risks kickback.

Why Saw Blade Materials Make or Break Your Project

Ever watched sawdust fly, only to end up with a splintered mess or a smoking blade? Blame the wrong material. Saw blades aren’t one-size-fits-all. The material your blade is made from determines everything: cut quality, speed, longevity, and even safety. Whether you’re building a bookshelf, cutting pipes, or tiling a bathroom, choosing the right saw blade material is the difference between frustration and flawless results. In this 2024 guide, we cut through the confusion. You’ll learn exactly how HSS, carbide, diamond, and other materials perform, plus get pro tips to pick, use, and maintain blades like a seasoned pro. No more wasted money or ruined projects!

Understanding the Core Saw Blade Materials

Let’s break down the most common materials. Think of this as your blade material cheat sheet.

Visual guide about Saw Blade Materials Guide Expert Tips and Best Picks 2024

Image source: nypost.com

High-Speed Steel (HSS): The Budget Workhorse

HSS blades are the most affordable and common for basic woodworking. Made from hardened steel alloyed with tungsten, molybdenum, and chromium, they stay sharp longer than regular steel but wear out much faster than carbide on hardwoods or metal.

- Best for: Softwoods (pine, cedar), plywood, and occasional DIY projects.

- Pros: Cheap, readily available, flexible (less prone to shattering).

- Cons: Dulls quickly on hardwoods, metal, or abrasive materials like MDF. Not ideal for precision work.

- Pro Tip: Great for beginners practicing cuts on scrap wood. Keep a few on hand for quick, dirty jobs where blade life isn’t critical.

Carbide-Tipped: The Professional’s Powerhouse

Carbide-tipped blades feature ultra-hard tungsten carbide teeth brazed onto a steel body. This combo delivers exceptional heat resistance and edge retention. Carbide grades (C1-C4) indicate hardness—C3/C4 are best for hardwoods and metal.

- Best for: Hardwoods (oak, maple), plywood, MDF, laminates, non-ferrous metals (aluminum, copper), and plastic.

- Pros: Lasts 10-20 times longer than HSS. Maintains sharpness through dense materials. Cleaner cuts.

- Cons: More expensive. Brittle—can chip if impacted or used on nails. Requires proper setup to avoid vibration.

- Pro Tip: Invest in a good carbide blade for your main table saw or circular saw. It pays for itself in saved time and replacements. Always check for nail strikes—hitting metal can destroy carbide teeth.

Diamond Blades: Cutting the Uncuttable

Diamond blades use industrial diamonds bonded to a metal core. They grind rather than cut, making them essential for hard, brittle materials. Segmented (turbo) rims dissipate heat better than continuous rims.

- Best for: Concrete, brick, stone, ceramic tile, porcelain, and asphalt.

- Pros: Cuts materials other blades can’t touch. Long life with proper use.

- Cons: Expensive. Requires water cooling for most materials (dry cutting shortens life drastically). Loud and dusty.

- Pro Tip: Never dry-cut concrete or tile unless the blade is explicitly rated for it. Water prevents overheating and diamond loss. For tile, use a continuous rim “premium” blade for cleaner cuts. Learn how to spot wear in our guide on when a diamond blade is dull.

Bi-Metal (HSS + Spring Steel): Flexible & Tough

Bi-metal blades combine a flexible spring steel body with HSS teeth. This creates a blade that resists breaking during aggressive cuts or on uneven surfaces.

- Best for: Reciprocating saws (Sawzall blades) cutting wood with nails, metal pipes, demolition work.

- Pros: Shock-resistant. Good for mixed materials (e.g., wood + nails). Faster cutting than standard HSS in demolition.

- Cons: Not as sharp or long-lasting as carbide for pure wood or metal. Teeth can wear faster than solid carbide.

- Pro Tip: Essential for any reciprocating saw used in renovation. Look for “demolition” or “nail-cutting” labels. See our reciprocating saw blade guide for specific types.

Specialty Materials: Ceramic & Cermet

These high-end options push performance limits.

- Cermet (Ceramic + Metal): Blades with cermet teeth offer superior heat resistance and hardness over carbide. Best for: High-speed metal cutting (ferrous and non-ferrous) where extreme heat is generated. Common on metal-cutting circular saws.

- Ceramic: Used in some premium metal-cutting blades. Handles very high temperatures but can be brittle. Less common than cermet.

- Pro Tip: Overkill for most DIYers. Worth considering for professional metal fabricators doing volume work.

How to Choose the Perfect Blade Material for ANY Job

Follow this step-by-step decision tree:

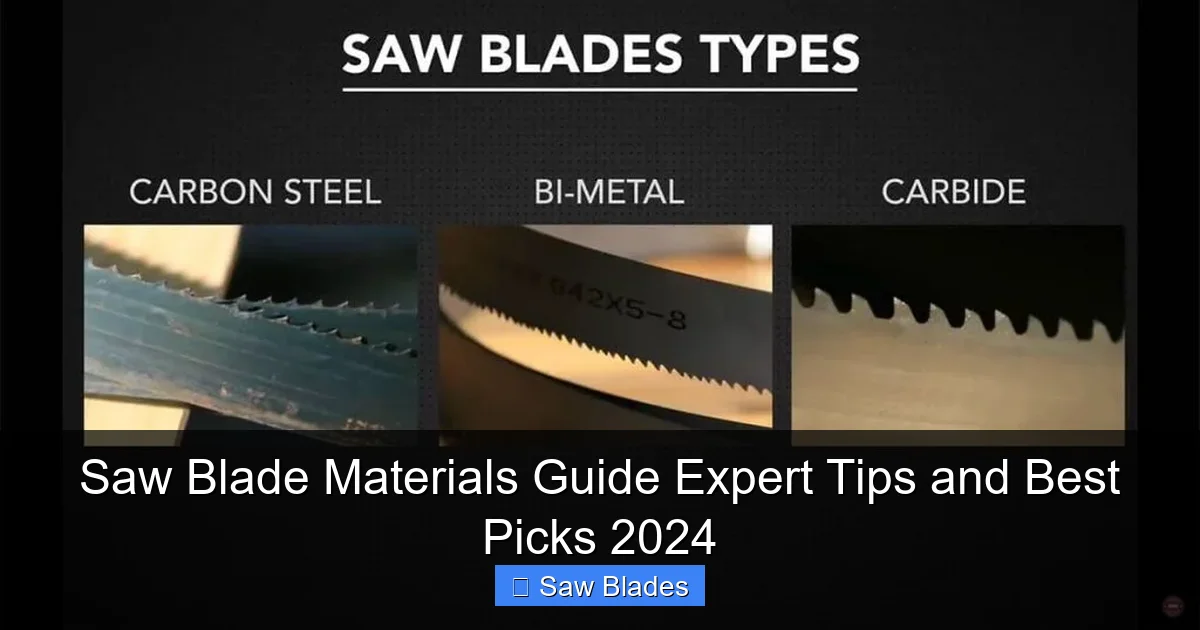

Visual guide about Saw Blade Materials Guide Expert Tips and Best Picks 2024

Image source: sawbladeuniversity.com

Step 1: Identify Your Material

- Wood (Softwood/Hardwood/Plywood/MDF): Carbide-tipped is king for quality and longevity. HSS works for softwoods only if budget is tight.

- Metal (Aluminum, Copper, Steel): Carbide-tipped for non-ferrous metals. Cermet or specialized metal-cutting blades (often labeled “ferrous” or “non-ferrous”) for steel. Never use a wood blade on metal!

- Tile/Stone/Concrete: Diamond blade, mandatory. Choose wet/dry based on your saw and project.

- Demolition (Mixed Materials): Bi-metal reciprocating blades.

Step 2: Consider Your Saw Type

- Circular Saw / Table Saw: Primarily carbide-tipped for wood/metal. Diamond for masonry (specialized saws only).

- Miter Saw: Carbide-tipped for wood. Specialized metal-cutting blades available.

- Reciprocating Saw: Bi-metal for versatility. Carbide grit for heavy metal.

- Jigsaw: HSS or bi-metal for wood/metal. Diamond grit for tile.

Need to swap blades? Always follow safe procedures. See how to change a circular saw blade correctly.

Step 3: Match Tooth Count & Geometry

Material isn’t the only factor! Tooth design drastically impacts performance:

- Wood Cutting:

- Rip Cuts (with the grain): Fewer teeth (18-24). Large gullets clear sawdust fast.

- Crosscuts (across the grain): More teeth (40-80). Finer teeth for smoother finish.

- General Purpose: 24-40 teeth. A good compromise.

- Metal Cutting: Finer teeth (18-32 TPI for circular saws). Alternate Top Bevel (ATB) or Triple Chip Grind (TCG) tooth patterns reduce heat and burrs.

- Tile/Stone: Continuous rim for smooth cuts, segmented rim for aggressive concrete cutting.

Step 4: Assess Your Budget & Frequency

- Occasional DIYer: One good general-purpose carbide blade (24-40 tooth) for wood. HSS for very light duty. Diamond blade only if tiling.

- Frequent Woodworker: Invest in dedicated rip and crosscut carbide blades. Consider a high-quality metal-cutting blade if needed.

- Professional: Build a collection: Specific blades for hardwoods, plywood, metal, and demolition. Prioritize higher-grade carbide (C3/C4).

Pro Maintenance: Extend Your Blade’s Life (and Save Money)

A well-maintained blade cuts better and lasts years. Neglect it, and you’ll be replacing it monthly.

Visual guide about Saw Blade Materials Guide Expert Tips and Best Picks 2024

Image source: tablesawmaster.com

Cleaning is Non-Negotiable

Pitch, resin, and sawdust gunk are blade killers. They insulate teeth, causing overheating and dulling.

- After Every Use: Wipe off excess debris with a dry cloth.

- Deep Clean (Weekly/Monthly):

- Remove the blade from the saw (always unplug first!).

- Soak in a bucket of warm water + blade cleaner or mild detergent for 10-15 mins.

- Scrub teeth gently with a brass wire brush (never steel—it scratches carbide). Focus on the gullets.

- Rinse thoroughly and dry completely before storage.

- Pro Tip: For stubborn pitch, use a dedicated blade cleaning solution. Avoid gasoline or harsh solvents—they damage blade coatings.

Storage Matters More Than You Think

- Never stack blades loosely: Teeth chip easily. Use blade guards or a dedicated blade storage case.

- Store flat or vertically: Avoid hanging blades by the arbor hole—it can warp the plate.

- Keep them dry: Moisture causes rust on steel bodies. A silica gel pack in your storage case helps.

Know When to Retire a Blade

Using a dull blade is dangerous and ruins your workpiece. Signs it’s time:

- Excessive burning or smoke during cuts.

- Chipped, broken, or visibly worn teeth.

- Cutting requires significant downward pressure.

- Rough, splintered edges instead of clean cuts.

- Visible rust that won’t scrub off.

Don’t sharpen carbide blades yourself unless you have professional equipment. It’s often cheaper to replace them. For HSS, professional sharpening can be cost-effective.

Troubleshooting Common Blade Problems

Even with the right material, things go wrong. Here’s how to fix it:

Problem: Burning Wood or Melting Plastic

- Cause: Dull blade, wrong tooth count (too many teeth for rip cuts), forcing the cut, or incorrect feed speed.

- Solution: Sharpen or replace blade. Use fewer teeth for ripping. Let the blade cut—don’t push hard. Ensure proper saw power for the material.

Problem: Chipping on Hardwood or Plywood Edges

- Cause: Dull blade, incorrect tooth geometry (e.g., ATB for ripping), or backing board needed for plywood.

- Solution: Use a sharp blade with the right grind (ATB for crosscuts, FTG for ripping). Cut plywood face-down on a sacrificial board. Reduce feed speed.

Problem: Blade Wobble or Vibration

- Cause: Warped blade, damaged arbor, incorrect blade installation, or using a blade not rated for your saw’s RPM.

- Solution: Inspect blade for flatness. Ensure proper installation (tighten arbor nut correctly—see your saw manual). Verify blade RPM rating matches your saw. Replace damaged blades.

Problem: Diamond Blade Sputtering or Rapid Wear

- Cause: Dry cutting (without water), incorrect blade for material, or excessive pressure.

- Solution: Always use water for concrete/stone unless blade is dry-cut rated. Match blade type to material (e.g., continuous rim for tile). Apply steady, moderate pressure—let the diamonds do the work.

Top Saw Blade Picks for 2024

Based on real-world testing and pro feedback:

Best All-Around Wood Blade (Circular/Table Saw)

Freud D0740X Diablo 40-Tooth ATB: C3 carbide, laser-cut stabilizer plates, Perma-SHIELD coating. Delivers smooth crosscuts in hardwoods and plywood. Great value.

Best Metal-Cutting Blade (Circular Saw)

Lenox Tools 7-1/4″ Metal Cutting Blade (14 TPI): Cermet II teeth, triple-chip grind. Cuts steel tubing and sheet metal cleanly with minimal burrs. Handles heat well.

Best Diamond Blade for Tile

Alpha ProLine 4″ Continuous Rim: Premium continuous rim, laser-welded segments. Wet or dry use (short bursts). Exceptionally smooth cuts on porcelain and ceramic tile.

Best Reciprocating Blade for Demolition

DEWALT DW4815 6″ Bi-Metal (10/14 TPI): Aggressive tooth design, shatter-resistant. Cuts wood with nails, metal pipes, and drywall effortlessly.

Conclusion: Cut Smarter, Not Harder

Choosing the right saw blade material isn’t rocket science—it’s about matching the tool to the task. Ditch the guesswork: HSS for softwood demos, carbide for serious woodworking and metal, diamond for masonry, and bi-metal for demolition chaos. Remember, a $50 carbide blade used correctly outlasts ten $10 HSS blades and delivers pro-quality cuts every time. Invest in the right material, clean your blades religiously, and respect their limits. Your projects will look better, your tools will last longer, and you’ll save serious cash in the long run. Now go cut with confidence—you’ve got this!

🎥 Related Video: Choosing the right saw blade for the job

📺 NuKraft Workshop – Builds, Deals & DIY

Table saws are incredibly versatile tools, capable of handling a wide range of cutting tasks with precision and efficiency. However …