Don’t risk dangerous slips or ruined projects by using worn saw blades. Knowing when to replace saw blades prevents injuries, saves money, and ensures clean cuts every time. This guide reveals the clear signs across all saw types so you can cut with confidence.

Key Takeaways

- Visual damage is critical: Replace blades immediately if you see cracked teeth, missing segments, or severe warping – these cause dangerous kickback.

- Performance tells the truth: If cuts require excessive force, produce excessive sawdust instead of chips, or burn wood, your blade is too dull.

- Safety trumps savings: A compromised blade risks severe injury; never push through resistance or use a blade with damaged arbor holes.

- Material matters: Diamond blades for concrete wear differently than wood-cutting blades; check segment loss or glazing specifically.

- Sharpness isn’t forever: Even unused blades degrade; inspect stored blades before use and replace if teeth are nicked or corroded.

- Listen to your saw: Unusual vibrations, grinding noises, or burning smells are urgent warnings to stop and inspect the blade.

- Prevention beats replacement: Proper storage, correct cutting speed, and using the right blade for the material significantly extends blade life.

Don’t Risk Cuts: Know Exactly When to Replace Saw Blades

That smooth, effortless cut you started with is suddenly a struggle. Your saw is working harder, the wood is burning, and you’re fighting the tool just to get through the material. Sound familiar? This isn’t just frustrating – it’s a major safety hazard. Using a worn or damaged saw blade significantly increases your risk of dangerous kickback, slips, and severe injury. Worse, you’re likely ruining your project with rough, inaccurate cuts. The good news? Knowing when to replace saw blades is simpler than you think. This guide cuts through the guesswork, giving you clear, actionable signs for every common saw type. Stop risking your safety and your project’s quality. Learn exactly when it’s time for a fresh blade.

Why Replacing Worn Blades Isn’t Optional (It’s Critical)

Ignoring a dull or damaged blade isn’t just about poor results; it’s a direct threat to your well-being. Here’s why timely replacement is non-negotiable:

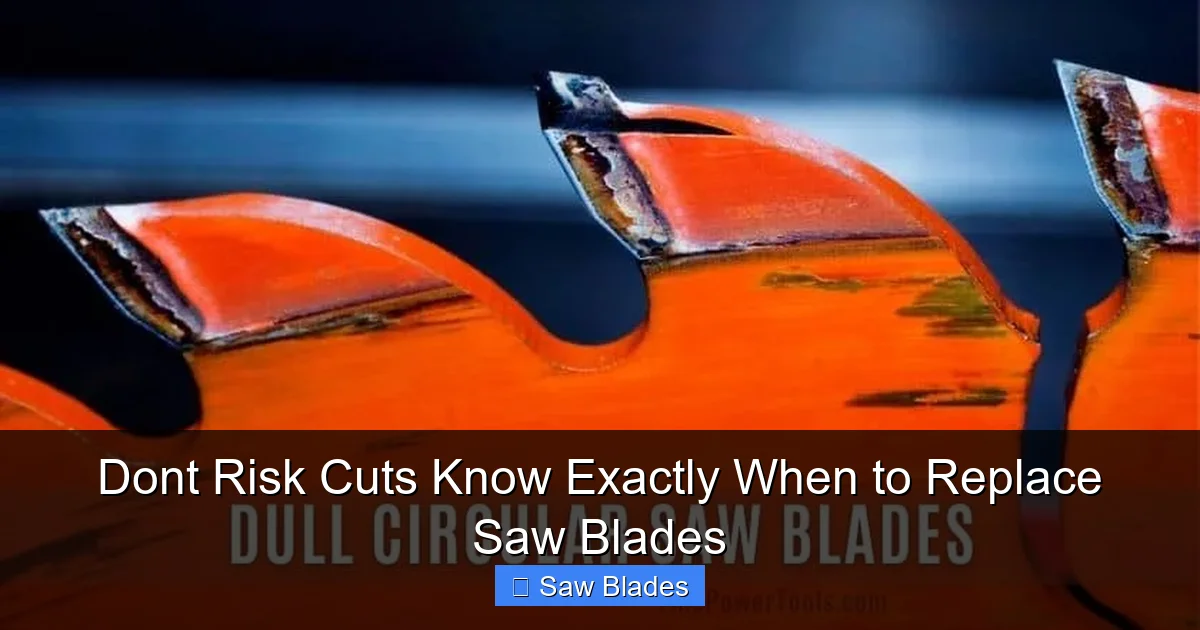

Visual guide about Dont Risk Cuts Know Exactly When to Replace Saw Blades

Image source: finepowertools.com

- Kickback Danger: Dull teeth grab and bind in the material, causing the saw to violently jerk back towards you. This is the #1 cause of serious table saw and circular saw injuries.

- Loss of Control: A blade that’s warped, damaged, or excessively dull requires excessive force. Your hands slip, your body strains, and control vanishes – leading to slips and cuts.

- Burning & Tear-Out: Dull blades generate excessive heat, burning wood (ruining finishes) and creating massive tear-out (splintering) on the cut line, especially on plywood and veneers.

- Motor Strain & Damage: Forcing a dull blade stresses your saw’s motor, potentially leading to overheating, reduced lifespan, or even electrical failure.

- Wasted Time & Money: Struggling through cuts takes longer, ruins materials, and ultimately costs more than a new blade. A sharp blade cuts faster and cleaner.

Replacing a blade at the right time is an investment in safety, project quality, and tool longevity. Don’t wait for a disaster.

Step 1: The Essential Visual Inspection (Do This BEFORE Every Major Cut)

Your eyes are your first line of defense. A quick visual check takes seconds but prevents major problems. Here’s what to look for:

Visual guide about Dont Risk Cuts Know Exactly When to Replace Saw Blades

Image source: sabrecut.com

Cracked, Chipped, or Missing Teeth

This is an immediate red flag. Even a single cracked or significantly chipped tooth can cause binding and kickback. Missing teeth (especially multiple) drastically reduce cutting efficiency and create uneven stress on the blade. Replace immediately if you see any damage to the cutting edges. Don’t try to “get by” – it’s not worth the risk.

Severe Warping or Bent Blade

Hold the blade up to a straight edge (like a level or the edge of a table). Look for significant gaps indicating the blade plate is bent. A warped blade won’t track straight, causes excessive vibration, and leads to inaccurate, rough cuts. Minor warping might be correctable by a professional, but significant bending means replace the blade.

Damaged or Worn Arbor Hole

The arbor hole is where the blade mounts onto the saw’s shaft. Check for cracks radiating from the hole, excessive wear (making the hole oval), or burrs. A damaged arbor hole means the blade won’t sit true, causing wobble, vibration, and potential detachment. Replace any blade with a compromised arbor hole – this is a critical safety failure point.

Rust, Corrosion, or Excessive Buildup

Surface rust on the blade plate might be cleaned, but heavy pitting or rust on the teeth weakens them. More importantly, check for hardened pitch, resin, or metal buildup (especially on carbide-tipped blades). While some buildup can be cleaned, heavy accumulation insulates the teeth, reducing cutting efficiency and heat dissipation. If cleaning doesn’t restore the teeth’s sharpness and exposure, it’s time for replacement. Proper how to store circular saw blades (in a dry, protective case) prevents this.

Diamond Blade Specifics: Segment Loss or Glazing

For concrete, masonry, or tile cutting:

- Segment Loss: If significant diamond segments are missing or worn down flush with the steel core, cutting efficiency plummets. The blade will glaze over and stop cutting effectively.

- Glazing: If the diamond segments appear smooth and shiny (like glass), the diamonds have worn down prematurely without exposing new ones. The blade “skates” on the surface instead of cutting. Replace glazed diamond blades. Learn more about spotting wear in our guide on how to tell if a diamond saw blade is dull.

Step 2: Performance Tests – Listen, Feel, and Observe

Your senses provide undeniable proof a blade needs replacing. Pay attention during cutting:

Visual guide about Dont Risk Cuts Know Exactly When to Replace Saw Blades

Image source: m.media-amazon.com

Excessive Force Required

If you’re pushing significantly harder than when the blade was new, or the saw is struggling to maintain speed (especially under load), the teeth are dull. A sharp blade should cut with moderate, consistent pressure. Fighting the saw is a clear sign it’s time for replacement.

Poor Cut Quality: Burning, Tear-Out, and Roughness

Inspect the cut immediately after making it:

- Burning: Dark, scorched marks along the cut line (especially on the top surface for table saws) indicate excessive heat from dull teeth. This ruins the wood’s appearance and weakens the cut edge.

- Excessive Tear-Out: Large splinters or chunks of material breaking off, particularly on the exit side of the cut (for handheld saws) or the back edge (for table saws). While some tear-out is normal, severe splintering points to dull teeth not shearing cleanly.

- Rough, Jagged Cut: Instead of a smooth, clean kerf, the cut looks rough, torn, or has significant sawdust packed into it. This indicates the teeth aren’t engaging properly.

Consistent poor cut quality, despite correct setup and technique, means the blade is past its prime. Replace it.

Unusual Noise and Vibration

Your saw should run relatively smoothly with a consistent cutting sound. Be alert for:

- Grinding or Scraping Noises: Often indicates the blade is rubbing against something (like a warped plate) or teeth are severely damaged.

- Excessive Vibration or Wobble: Feels like the saw is shaking uncontrollably. This could be due to a warped blade, damaged arbor hole, or severe imbalance. Vibration makes control difficult and increases fatigue.

- Burning Smell: A distinct odor of overheating wood or plastic is a major warning sign of excessive friction from a dull blade.

Any of these sensory cues mean stop cutting immediately and inspect the blade. Continuing is dangerous.

Sawdust vs. Wood Chips

This is a great indicator for wood-cutting blades:

- Sharp Blade: Produces consistent, coarse wood chips (especially with ripping blades) or fine, even sawdust (with crosscut blades).

- Dull Blade: Produces excessive, fine, powdery sawdust regardless of the cut type. The blade is essentially sanding the wood instead of cutting it, generating massive heat.

If you’re getting mostly fine dust instead of chips, your blade is too dull and needs replacement.

Step 3: Material-Specific Replacement Clues

Different materials wear blades differently. Know what to watch for:

Wood (Circular Saws, Table Saws, Miter Saws, Band Saws)

- Carbide-Tipped Blades: Look for rounded, polished-looking cutting edges on the carbide tips (use a magnifying glass). Check for chipped or missing tips. Performance decline (burning, tear-out, force) is the key indicator.

- High-Speed Steel (HSS) Blades: Become visibly dull quickly. Look for a loss of the sharp, defined edge – it will appear rounded and shiny. Performance drop is rapid.

- Band Saw Blades: Check for broken or missing teeth, excessive wear on the gullet (the curve behind the tooth), and “set” (the sideways bend of teeth) that’s worn away. A blade that wanders significantly or produces excessive sawdust needs replacing. While sharpening is possible, know how to sharpen band saw blades is a skill; often replacement is more cost-effective for heavily worn blades.

Metal (Cold Saws, Band Saws, Reciprocating Saws)

- Bi-Metal Blades (Reciprocating, Band Saws): Look for broken or severely worn teeth, especially the hard metal tips. Check for “work hardening” – the blade becomes brittle and snaps. Performance: slow cutting, excessive burrs on the cut edge, or the blade stopping mid-cut.

- Carbide-Tipped Metal Blades: Similar to wood blades – look for rounded, polished carbide tips and chipping. Performance decline is key.

Metal cutting generates intense heat; blades dull faster. Don’t push through resistance. Learn about blade selection in our reciprocating saw blades guide.

Concrete, Masonry, Tile (Diamond Blades)

- Segment Loss: As mentioned, missing or worn-down segments.

- Glazing: Smooth, shiny segments.

- Core Warping: Diamond blades can warp under extreme heat. Check for flatness.

- Performance: Blade stops cutting, requires excessive pressure, produces excessive dust instead of slurry, or makes a high-pitched squealing noise.

Diamond blades have a finite life. When cutting efficiency drops significantly, replace it.

Step 4: The Replacement Threshold – When is it REALLY Time?

It’s not always black and white. Consider these factors:

The “Cost vs. Benefit” Test

Ask yourself:

- Is the time saved by using a sharp blade (faster cuts, less sanding) worth the cost of a new blade?

- Is the risk of injury or ruined material higher than the blade’s price?

- For hobbyists: Is the frustration of poor cuts ruining the enjoyment?

- For pros: Is the lost productivity and potential rework costing more than the blade?

In almost all cases, especially when safety is a concern, the answer is “yes” – replace the blade.

Frequency Guidelines (General Starting Points)

These are estimates; actual life depends on material, blade quality, and usage intensity:

- Carbide-Tipped Wood Blades (Circular/Table): 50-150+ linear feet of cutting (varies wildly). Inspect after every project.

- HSS Wood Blades: 10-30 linear feet. Inspect frequently.

- Band Saw Blades (Wood): 10-50 hours of cutting. Inspect daily.

- Bi-Metal Reciprocating Blades (Wood/Metal): 5-20 cuts (depending on thickness/material). Inspect after each cut session.

- Diamond Blades (Concrete): 10-50+ linear feet (depends on hardness, wet/dry). Inspect after each use.

Never rely solely on time or distance. Always prioritize the visual and performance checks outlined above. A blade used for soft pine will last much longer than one used for hard maple or abrasive composites.

When Sharpening Isn’t the Answer (Replace Instead)

Sharpening extends life, but has limits:

- Carbide Blades: Can usually be sharpened 2-5 times *if* the carbide tips are intact and not chipped. Once tips are damaged or significantly reduced in size, sharpening isn’t effective – replace.

- HSS Blades: Can be sharpened many times, but eventually the tooth geometry becomes too small or damaged. If sharpening doesn’t restore performance, replace.

- Severe Damage: Cracked teeth, missing segments, warped plates – sharpening won’t fix these. Replace immediately.

- Cost: If professional sharpening costs 50% or more of a new blade, replace it.

Knowing how to change the blade on a Ryobi table saw or your specific tool makes replacement quick and easy – don’t let hesitation keep you using a dangerous blade.

Troubleshooting: “My Blade Seems Okay, But…”

Still unsure? Address these common confusions:

“The teeth look sharp, but cuts are rough.”

This often points to dullness on the back angle or clearance angle of the tooth, not just the cutting edge. These angles are crucial for chip removal and reducing friction. Even if the front edge looks ok, if performance is poor, the blade is functionally dull. Replace it. Also, check your saw’s alignment (fence, miter gauge) – misalignment causes rough cuts even with a sharp blade.

“I’m getting tear-out, but only on plywood/veneer.”

While dull blades exacerbate tear-out, this material is inherently prone to it. Ensure you’re using a high-tooth-count blade (80+ for table saws) specifically designed for plywood. Apply masking tape over the cut line. Support the back edge firmly (use a zero-clearance insert on table saws, or a sacrificial board underneath). If tear-out is severe *despite* these measures and a sharp blade, the blade might still be contributing – consider replacement.

“My saw vibrates, but the blade looks fine.”

Rule out other causes first:

- Is the blade securely tightened to the correct torque?

- Is the arbor flange (the washer) clean and undamaged?

- Is the saw itself stable (e.g., table saw not wobbling on its stand)?

- Is the material being cut supported properly?

If vibration persists after checking these, the blade *could* be slightly warped or imbalanced. Try the blade on another saw if possible. If vibration remains, replace the blade.

Conclusion: Safety and Quality Start with a Sharp Blade

Knowing when to replace saw blades isn’t about memorizing arbitrary timelines; it’s about developing the habit of vigilant inspection and listening to your tools and materials. That slight increase in effort, the faint smell of burning, the rough edge on your cut – these are your saw’s urgent messages. Ignoring them risks serious injury, wasted time, ruined projects, and damage to your equipment.

Make the visual check part of your pre-cut routine. Pay attention to how the saw feels and sounds. Understand the specific wear patterns for your blade type and material. When in doubt, err on the side of caution – replace the blade. The cost of a new blade is trivial compared to the cost of an emergency room visit or a scrapped project.

Investing in timely blade replacement is investing in your safety, your craftsmanship, and the longevity of your tools. Keep your cuts clean, your projects perfect, and your fingers intact. Don’t risk cuts – know exactly when to replace your saw blades.

🎥 Related Video: Dull Saw Blade? | Here Are 5 Ways To Tell If Your Table Saw Blade Is DULL!

📺 Detroit DIY

In this video, “Dull Saw Blade? | Here Are 5 Ways To Tell If Your Table Saw Blade Is DULL!” I will share 5 ways that you can tell if …