Unlock the secret to flawless cuts by understanding saw blade TPI meaning! This guide explains exactly what Teeth Per Inch is, how it impacts cutting speed and finish, and gives you the precise TPI recommendations for every material—from plywood to metal. Stop guessing and start cutting perfectly every time.

Key Takeaways

- TPI = Teeth Per Inch: This number tells you how many cutting teeth are on each inch of the blade. It’s the key to matching your blade to your material.

- Low TPI = Fast, Rough Cuts: Blades with fewer teeth (4-10 TPI) cut quickly through thick, soft materials like dimensional lumber but leave a rough edge.

- High TPI = Slow, Smooth Cuts: Blades with many teeth (20-80+ TPI) cut slowly through thin, hard materials like plywood or metal, delivering a clean, splinter-free finish.

- Material Dictates TPI: Always choose TPI based on what you’re cutting—wood, metal, plastic, or tile each need specific ranges for best results.

- Blade Type Matters Too: Circular saws, reciprocating saws, and band saws all have different typical TPI ranges; know your tool’s requirements.

- Geometry is Crucial: Tooth shape (ATB, FTG, etc.) works with TPI. A high-TPI blade with the wrong geometry won’t perform well.

- Start Simple: For general woodcutting, a 24-40 TPI circular saw blade is a versatile “do-it-all” choice for most DIY projects.

What is Saw Blade TPI Meaning? Your Cutting Secret Decoded

Ever stood in the hardware store aisle, staring at a wall of saw blades, completely confused by numbers like “24 TPI” or “80 TPI”? You’re not alone! That “TPI” label holds the key to whether your next cut will be a masterpiece or a messy disaster. Saw blade TPI meaning is simple: it stands for Teeth Per Inch. It tells you exactly how many cutting teeth are packed onto each inch of the blade’s cutting edge. Think of it like the blade’s “personality” – it determines if the blade is a speed demon for rough work or a precision artist for fine finishes.

Understanding TPI isn’t just technical jargon; it’s the difference between a project that looks professional and one that screams “beginner.” Using the wrong TPI can lead to burned wood, chipped edges, excessive sawdust, or even a dangerous kickback. This guide cuts through the confusion. You’ll learn exactly what TPI means, how it affects your cuts, and most importantly, how to choose the perfect TPI for any material and any saw. Whether you’re building a deck, crafting furniture, or tackling a metal project, mastering TPI is your ticket to perfect cuts, every single time.

What Does TPI Actually Mean? (It’s Simpler Than You Think!)

Let’s break down “Teeth Per Inch” without the engineering textbook. Imagine taking a ruler and placing it right against the cutting edge of your saw blade. Now, count how many individual teeth fit into that one-inch space. That number is the TPI.

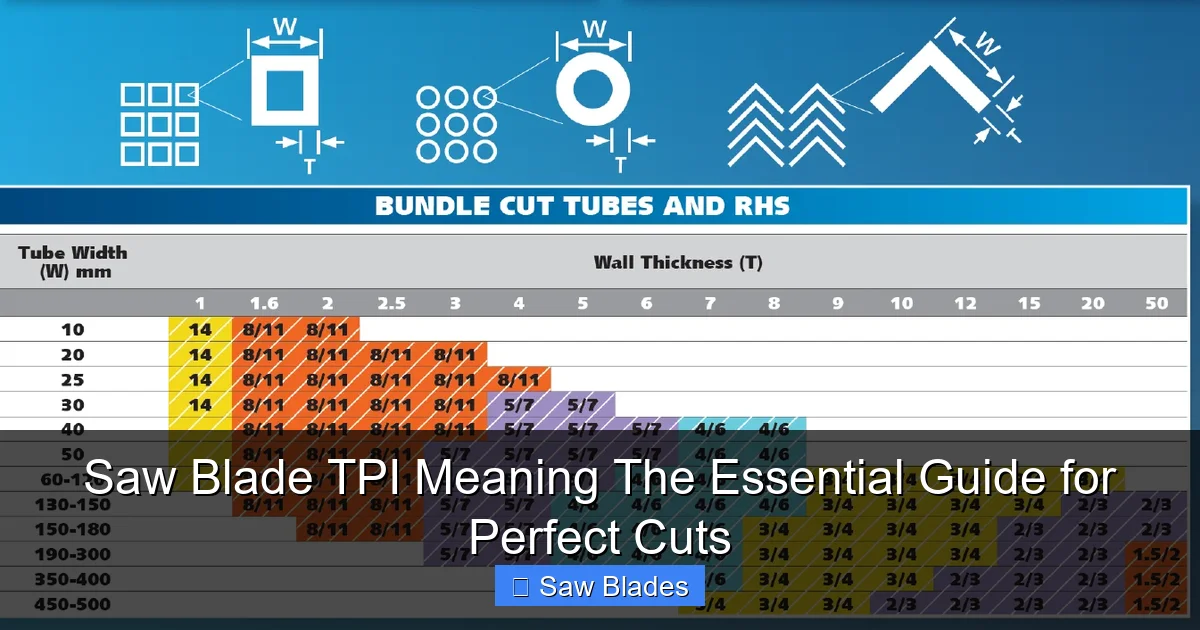

Visual guide about Saw Blade TPI Meaning The Essential Guide for Perfect Cuts

Image source: sawblade.com.au

Why TPI Matters: The Core Principle

TPI directly controls two critical aspects of your cut:

- Cutting Speed: Blades with fewer teeth (low TPI) have bigger gaps between teeth (called “gullet size”). This allows sawdust to escape easily, so the blade can move through material much faster. It’s like a wide-open highway for the blade.

- Cut Quality (Finish): Blades with more teeth (high TPI) have smaller gaps. Each tooth removes a tiny bit of material, resulting in many more cuts per inch. This creates a much smoother, cleaner, splinter-free finish. It’s like using fine sandpaper instead of coarse.

The golden rule: Low TPI = Fast & Rough. High TPI = Slow & Smooth. Getting this balance right for your specific material is the heart of choosing the perfect blade.

TPI vs. RPM: Why Both Matter

TPI doesn’t work alone! The speed of your saw (RPM – Revolutions Per Minute) interacts with TPI. A high-TPI blade on a very fast saw (like many circular saws) can overheat and burn material because the teeth don’t have time to clear sawdust. Conversely, a low-TPI blade on a slow saw might chatter and produce a poor finish. Always consider your saw’s capabilities alongside TPI. For instance, reciprocating saws (like Sawzalls) operate at lower speeds than circular saws, influencing their typical TPI ranges.

How TPI Affects Your Cut: Speed, Finish & Material Matters

Choosing the right TPI transforms your cutting experience. Here’s exactly what happens with different TPI ranges:

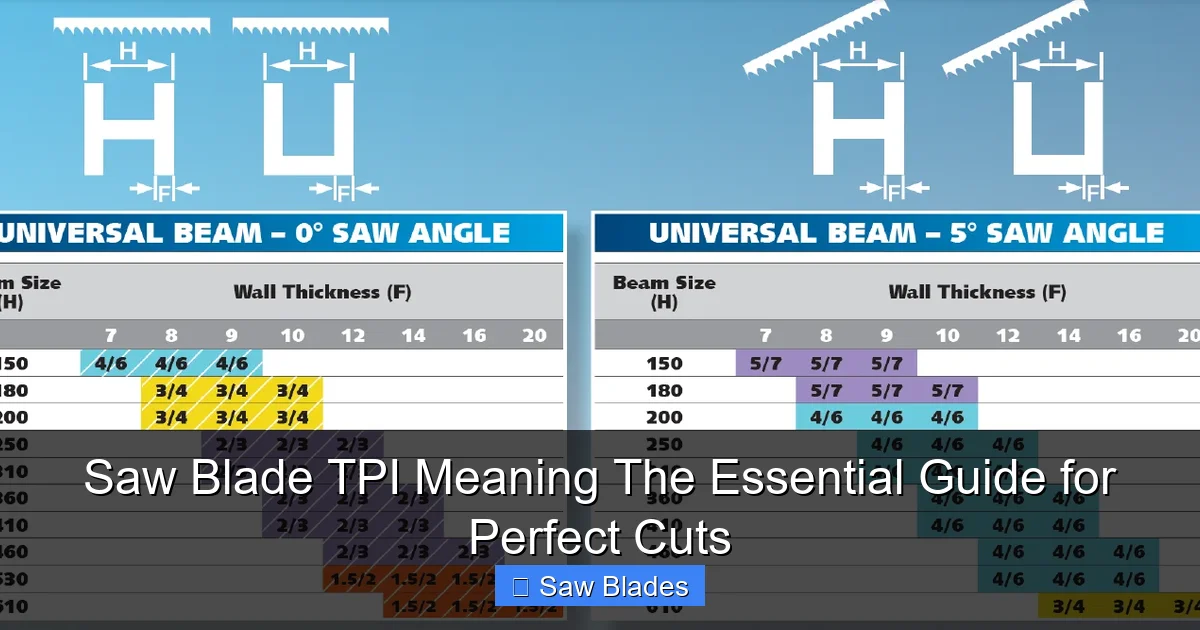

Visual guide about Saw Blade TPI Meaning The Essential Guide for Perfect Cuts

Image source: sawblade.com.au

Low TPI Blades (4-10 TPI): The Rough & Ready Cutters

- Best For: Thick, soft materials where speed and aggression are key, and a smooth finish isn’t critical. Think dimensional lumber (2x4s, 2x6s), rough framing, plywood edges (if speed is priority), and demolition work.

- What You Get: Blazing fast cutting speed. Large gullets clear sawdust efficiently, preventing overheating in thick stock. However, the large teeth create significant vibration and leave a very rough, splintered, or “saw-toothed” edge. Expect lots of tear-out, especially on the backside of plywood.

- Typical Uses: Framing carpentry, rough cutting lumber to length, demolition cuts in wood or drywall, cutting thick plastic pipes. Often found on reciprocating saw blades for demolition.

Medium TPI Blades (10-24 TPI): The Versatile Workhorses

- Best For: The sweet spot for many general woodcutting tasks. Good balance for dimensional lumber, plywood, MDF, and softer metals like aluminum.

- What You Get: A solid compromise. Faster than high-TPI blades but significantly smoother than low-TPI. Reduced tear-out compared to low-TPI, especially with proper technique (using masking tape or a sacrificial board). Still efficient at clearing sawdust for most common thicknesses.

- Typical Uses: General carpentry, cutting plywood sheets, trimming doors, cutting 2x lumber, light metal cutting (aluminum). This is often the “default” range for many circular saw blades.

High TPI Blades (24-80+ TPI): The Precision Artists

- Best For: Thin materials, hardwoods, fine woodworking, metal cutting (ferrous and non-ferrous), plastics, and laminates where a flawless finish is essential.

- What You Get: Exceptionally smooth, clean cuts with minimal splintering or tear-out. Ideal for finish carpentry, cabinetry, and metal fabrication. However, cutting speed is much slower. Small gullets can clog easily with sawdust in thicker materials, leading to overheating, burning (especially wood), or blade binding. Requires a slower feed rate.

- Typical Uses: Cutting plywood for furniture (especially veneered), hardwoods, acrylic/plexiglass, thin metal sheets (like flashing or auto body), laminate countertops, fine moldings. Essential for clean cuts in metal with the right blade type (e.g., metal-cutting circular saw blades).

TPI Recommendations: What Number for What Material?

This is the magic question! There’s no single “best” TPI; it depends entirely on what you’re cutting and how thick it is. Use this as your go-to cheat sheet:

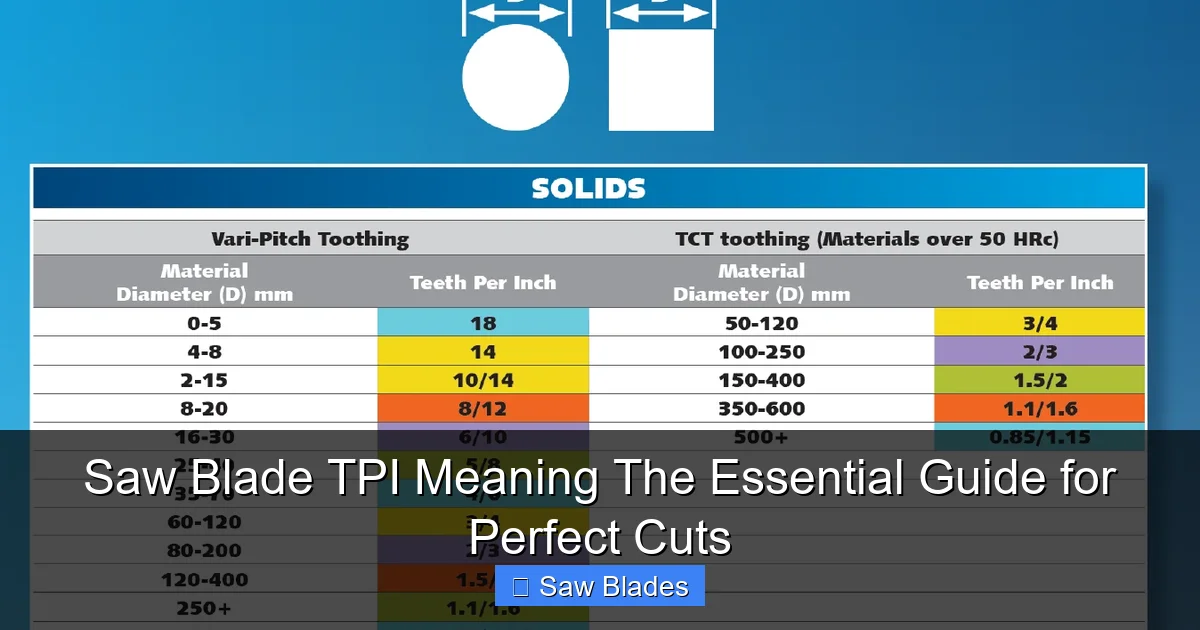

Visual guide about Saw Blade TPI Meaning The Essential Guide for Perfect Cuts

Image source: sawblade.com.au

Cutting Wood: The Most Common Task

| Material & Thickness | Recommended TPI Range | Why This TPI? |

|---|---|---|

| Rough Lumber (2x4s, 2x6s, Framing) Up to 1.5″ thick |

10-18 TPI | Balances speed and reasonable finish for structural work. Low enough for speed, high enough to reduce excessive splintering. |

| Plywood, OSB, MDF (General) 1/4″ to 3/4″ thick |

24-40 TPI | Higher TPI minimizes tear-out on the fragile veneer faces. 24-32 TPI is common for general plywood; 40+ TPI for very fine veneers or critical surfaces. |

| Hardwoods (Oak, Maple, Cherry) 1/4″ to 1.5″ thick |

32-60 TPI | Hardwoods are dense. Higher TPI creates the smoothest finish, especially important for visible edges in furniture. Lower end (32-40) for thicker stock, higher end (50-60) for thin stock or fine work. |

| Softwoods (Pine, Cedar) – Finish Work 1/2″ to 1″ thick |

24-36 TPI | Similar to plywood. Higher TPI prevents splintering on the often softer, more brittle surfaces. |

| Thin Wood (Luan, Veneer, Trim) Less than 1/4″ thick |

60-100+ TPI | Very high TPI is essential to prevent chipping and splintering on delicate thin materials. Often found on specialized fine-cutting blades. |

Cutting Metal: Precision is Paramount

| Material & Thickness | Recommended TPI Range | Why This TPI? |

|---|---|---|

| Aluminum, Copper, Non-Ferrous Metals Up to 1/8″ thick |

24-36 TPI | Medium-high TPI provides enough teeth for smooth cutting without excessive heat buildup in softer metals. Requires proper coolant/lubrication. |

| Aluminum, Non-Ferrous Metals 1/8″ to 1/4″ thick |

18-24 TPI | Slightly lower TPI helps clear chips from thicker sections of softer metals, preventing clogging and overheating. |

| Mild Steel, Stainless Steel Up to 1/8″ thick |

32-60 TPI | High TPI is critical for clean cuts in hard metals. More teeth distribute the cutting load, reducing heat and burrs. *Requires specialized metal-cutting blade (Carbide Tipped or Bi-Metal). |

| Mild Steel, Stainless Steel 1/8″ to 1/4″ thick |

24-32 TPI | Lower TPI helps manage chip clearance in thicker ferrous metals, though cutting speed will be slow. Still requires a dedicated metal blade. |

| Thin Metal (Flashing, Auto Body) Less than 1/16″ thick |

60-100+ TPI | Very high TPI prevents the thin metal from distorting or creating excessive burrs. Often found on fine-cutting hacksaw or specialized metal-cutting circular saw blades. |

Crucial Metal Note: Always use a blade specifically designed for metal! Wood blades will quickly overheat and ruin both the blade and your cut. Look for “Metal Cutting,” “Ferrous” or “Non-Ferrous” labels. Cutting metal generates extreme heat – use cutting oil or coolant whenever possible.

Cutting Plastics, laminates & Other Materials

- Acrylic/Plexiglass: 60-100+ TPI (Fine Tooth, often ATB grind). High TPI prevents melting and chipping. Use a slow speed and sharp blade. A dedicated plastic-cutting blade is best.

- PVC, ABS Pipe: 24-40 TPI (Medium). Lower TPI clears plastic chips well and prevents melting/binding. A standard wood blade often works, but a plastic-cutting blade is superior.

- Laminate (Countertops): 40-80 TPI (Fine Tooth, often FTG or ATB). High TPI prevents chipping the fragile laminate surface. Use a blade specifically for laminates.

- Tile (Ceramic/Porcelain): N/A – Diamond Blades! Tile saws use continuous rim or turbo rim diamond blades, not TPI. The “grit” size matters more than TPI here. See our guide on cutting glass with a tile saw for specifics.

Tooth Geometry: TPI’s Partner in Cutting Performance

TPI tells you *how many* teeth, but the *shape* of those teeth (tooth geometry) determines *how* they cut. The right geometry combined with the right TPI is essential for optimal performance. Here are the most common types:

Alternate Top Bevel (ATB)

- Description: Teeth are ground with alternating bevels (left/right) on the top edge. Creates a shearing action.

- Best With: Medium to High TPI (24+ TPI). Excellent for clean crosscuts and general-purpose cutting in wood, plywood, and plastics. Provides a very smooth finish.

- Why it Works with TPI: The shearing action complements the fine cuts made by higher TPI, minimizing tear-out.

Flat Top Grind (FTG)

- Description: Teeth have a flat top edge. Cuts with a scraping/chiseling action.

- Best With: Low to Medium TPI (10-24 TPI). Ideal for fast rip cuts in wood (cutting *with* the grain) and rough cutting. Less prone to grabbing.

- Why it Works with TPI: The aggressive scraping action is efficient for removing larger amounts of material quickly, which aligns with the speed focus of lower TPI blades.

Triple Chip Grind (TCG)

- Description: Features a combination of flat-top “raker” teeth and beveled teeth. Designed for hard, brittle materials.

- Best With: Medium to High TPI (18-40 TPI), especially for metal and hard plastics. Excellent for cutting aluminum, copper, and non-ferrous metals without chipping.

- Why it Works with TPI: The raker teeth clear chips effectively, which is crucial when using higher TPI on dense metals to prevent clogging and heat buildup.

Combination (ATB + Raker)

- Description: Typically 5 teeth: 4 ATB teeth followed by 1 flat raker tooth. The raker clears sawdust, the ATB teeth finish the cut.

- Best With: Medium TPI (18-24 TPI). The most common general-purpose wood blade geometry. Good balance for both crosscuts and rips.

- Why it Works with TPI: The raker tooth solves the sawdust clearance issue that can plague medium-TPI blades during longer cuts, maintaining speed and finish.

Key Insight: A high-TPI blade with FTG geometry might still tear out plywood badly. A low-TPI blade with ATB geometry might be too slow and burn wood. Always consider TPI *and* geometry together for your material.

Blade Types & Their Typical TPI Ranges

Different saws have different cutting actions and speeds, leading to distinct TPI norms. Knowing your saw type is step one!

Circular Saw Blades

- Typical TPI Range: 18 TPI (very rough) to 80+ TPI (ultra-fine).

- Common Uses: Framing (10-18 TPI), General Woodcutting (24-40 TPI), Plywood/Finish Work (40-60 TPI), Metal Cutting (24-60 TPI – *special blades*), Plastics (60+ TPI).

- Why the Range? Circular saws run at high RPM (3,500-5,000+). Higher TPI blades need slower feed rates to prevent burning. Lower TPI blades excel at speed in thick stock. Always ensure your blade is rated for your saw’s RPM! Changing blades is straightforward – see how to change a circular saw blade safely.

Reciprocating Saw Blades (Sawzall Blades)

- Typical TPI Range: 5 TPI (demo) to 24 TPI (fine metal/plastic).

- Common Uses: Demolition (5-8 TPI – wood/metal), General Cutting (8-14 TPI – wood, pipe), Fine Cutting (14-24 TPI – metal, thin wood, plastic).

- Why the Range? Reciprocating saws have a slower, reciprocating action. Lower TPI is dominant for aggressive cutting in demo. Higher TPI is used for precision work in metal or finish carpentry where the saw’s maneuverability shines. Explore the full range in our reciprocating saw blades guide.

Band Saw Blades

- Typical TPI Range: 3 TPI (resawing thick wood) to 24 TPI (fine metal cutting).

- Common Uses: Resawing/Rough Cutting (3-6 TPI), General Woodcutting (6-14 TPI), Curves/Fine Wood (14-18 TPI), Metal Cutting (10-24 TPI).

- Why the Range? Band saws have a continuous cutting action. Very low TPI (3-6) is used for thick stock resawing where chip clearance is critical. Higher TPI is used for thinner stock and finer finishes. Tooth geometry (like skip tooth or hook tooth) is also very important here.

Jigsaw Blades

- Typical TPI Range: 8 TPI (rough wood) to 30+ TPI (fine metal/plastic).

- Common Uses: Rough Wood (8-10 TPI), General Wood/Curves (10-14 TPI), Plywood/Fine Wood (14-21 TPI), Metal (18-30+ TPI), Plastics (21+ TPI).

- Why the Range? Jigsaws have a fine, reciprocating action ideal for curves. TPI choices are similar to reciprocating saws but often slightly higher for finer finishes on smaller cuts.

Miter Saw & Table Saw Blades

- Typical TPI Range: 24 TPI (general) to 80+ TPI (ultra-fine crosscuts).

- Common Uses: General Woodcutting (24-40 TPI), Fine Crosscuts/Plywood (40-60 TPI), Hardwood/Metal (60+ TPI – *special blades*). Often feature combination (ATB+Raker) geometry.

- Why the Range? These stationary saws prioritize cut quality. Higher TPI is common for finish work. Dedicated crosscut blades often have higher TPI (60+) than general-purpose blades. For critical angle cuts, understand your saw’s capabilities like a dual bevel miter saw.

How to Choose the Perfect TPI: A Step-by-Step Guide

Stop guessing! Follow this simple process to pick the right TPI every time:

Step 1: Identify Your Material & Thickness

This is NON-NEGOTIABLE. Is it pine 2×4? Oak plywood? Aluminum sheet? Stainless steel tube? Measure the thickness accurately. Refer back to the material tables in Section 3. Material and thickness dictate the TPI range.

Step 2: Determine Your Priority: Speed or Finish?

- Need it done fast for framing? Lean towards the lower end of the TPI range for that material.

- Need a showroom-quality edge for furniture? Lean towards the higher end of the TPI range.

- Doing general work? Aim for the middle of the recommended range.

Step 3: Consider Your Saw Type

Are you using a circular saw, reciprocating saw, or band saw? Check Section 5 for typical TPI norms for your specific tool. A 60 TPI blade is great for a circular saw on plywood but might be too fine for a reciprocating saw on thick wood.

Step 4: Don’t Forget Tooth Geometry

Once you have your TPI range, look for the right geometry:

- Wood (General/Crosscuts): ATB or Combination (ATB+Raker)

- Wood (Rips/Rough): FTG

- Metal (Non-Ferrous): TCG

- Metal (Ferrous): ATB or TCG (Specialized blades only!)

- Plastics/Laminate: ATB

Avoid FTG for fine finishes in wood or metal.

Step 5: Check Blade Specifications & Quality

Ensure the blade is rated for your material (wood, metal, multi-material) and your saw’s RPM. Cheap blades often have poor tooth geometry and dull quickly. Invest in a quality blade from a reputable brand (Freud, Diablo, Lenox, Bosch, etc.) for better results and longevity. A dull blade, even with perfect TPI, will perform poorly – learn how to tell if a blade is dull (principles apply to all blades).

Step 6: Start Simple (For Beginners)

If you’re new to saw blades, get a versatile 24-40 TPI ATB or Combination blade for your circular saw. It will handle 80% of general woodcutting tasks (dimensional lumber, plywood) reasonably well. Add specialized blades (like a 60 TPI for fine plywood or a metal-cutting blade) as your projects demand.

Troubleshooting Common TPI-Related Cutting Problems

Still having issues? Your TPI choice might be the culprit:

Problem: Excessive Tear-Out / Splintering (Especially on Plywood Backside)

- Likely Cause: TPI too LOW for the material thickness/veneer.

- Solution: Use a blade with higher TPI (40-60+) and ATB geometry. Support the back of the cut with sacrificial wood or use masking tape. Feed the saw slower.

Problem: Burning / Scorching on Wood

- Likely Cause 1: TPI too HIGH for the material thickness/saw speed (sawdust can’t clear, friction builds heat).

- Solution 1: Switch to a blade with lower TPI (18-24 for thicker wood) or use a blade with a raker tooth (Combination geometry) for better chip clearance. Feed the saw slower.

- Likely Cause 2: Blade is DULL.

- Solution 2: Replace the blade. A dull blade generates excessive heat regardless of TPI.

Problem: Blade Binding / Stalling in Thick Material

- Likely Cause: TPI too HIGH for the material thickness (gullets clog with sawdust).

- Solution: Use a blade with lower TPI (10-18 for thick dimensional lumber) or ensure you have a blade with large gullets and raker teeth. Make multiple shallow passes instead of one deep cut.

Problem: Rough, Choppy Cut in Metal

- Likely Cause 1: TPI too LOW for the metal thickness (teeth are too aggressive, causing chatter).

- Solution 1: Use a blade with higher TPI (24-36 for 1/8″ steel) and the correct geometry (TCG for non-ferrous, ATB for ferrous).

- Likely Cause 2: Using a WOOD blade on metal.

- Solution 2: ALWAYS use a blade specifically designed for metal! Wood blades will fail quickly and dangerously.

Problem: Excessive Vibration / Poor Cut Quality

- Likely Cause: TPI mismatch OR incorrect geometry for the cut type (e.g., using FTG for fine crosscuts).

- Solution: Ensure TPI is appropriate for material/thickness AND geometry matches the cut (ATB for crosscuts, FTG for rips). Check blade is sharp and securely mounted.

Conclusion: Master TPI, Master Your Cuts

Understanding saw blade TPI meaning – Teeth Per Inch – is no longer a mystery. It’s the fundamental language of blade selection that directly controls whether your cut is fast and rough or slow and silky smooth. Remember the core principle: Low TPI = Fast & Rough. High TPI = Slow & Smooth.

By matching the TPI (and tooth geometry!) to your specific material, thickness, and the type of cut you need, you unlock precision, efficiency, and professional results. No more burnt edges, excessive tear-out, or frustrating blade stalls. Start with the material tables in this guide, consider your saw type, and prioritize either speed or finish. Invest in a few quality blades covering the key TPI ranges for your most common projects – a good 24-40 TPI general wood blade and a 60+ TPI fine-cut blade are excellent starters.

Mastering TPI is a simple yet powerful skill that elevates every project. Stop letting the wrong blade hold you back. Choose wisely, cut confidently, and enjoy the satisfaction of perfect cuts, time after time. Your next project deserves nothing less.

🎥 Related Video: Beginner Woodworker Tips on Buying the Right Saw Blades

📺 731 Woodworks

What is the best saw blade for a table saw? Best saw blade for miter saw? Best saw blade for hardwood? This is the beginner …