Oiling saw blades takes just 5 minutes but prevents costly rust and dulling. This guide shows you the simple steps to protect your blades after every use. Keep your cuts precise and your tools lasting years longer with this essential habit.

Key Takeaways

- Prevent rust instantly: Oil creates a barrier against moisture, stopping corrosion before it starts – crucial for stored blades.

- Extend blade life significantly: Proper oiling reduces friction and wear, saving you money on frequent replacements.

- Maintain cutting performance: Clean, oiled blades glide through wood smoothly, giving cleaner cuts and less strain on your saw.

- Works for all common saw types: Circular, band, miter, and reciprocating saw blades all benefit from this quick maintenance.

- Safety first: Always wear gloves and eye protection when handling blades, even during oiling.

- Frequency is key: Oil blades after every use, especially if storing them for more than a day.

- Use the right oil: Machine oil or dedicated blade oil works best – avoid household oils that gum up.

Why Oiling Saw Blades is a 5-Minute Game Changer

That trusty saw blade you rely on for clean cuts? It’s silently fighting a battle against rust and corrosion every time it sits unused. Moisture in the air, sawdust residue, and even the oils from your skin can start degrading your blade within hours. The result? Dull edges, rough cuts, and blades that need replacing way too soon. But here’s the good news: oiling saw blades takes less than 5 minutes and solves these problems instantly. Think of it like putting a raincoat on your blade – it’s a simple shield against the elements. Whether you’re a weekend DIYer or a pro contractor, this habit transforms blade longevity and performance. In this guide, you’ll learn exactly how to oil saw blades quickly, safely, and effectively. No special tools, no complicated steps – just straightforward maintenance that pays off in smoother cuts and fewer replacements.

Why Your Saw Blades NEED Oil (The Science Made Simple)

You might wonder, “Can’t I just wipe off the sawdust and call it a day?” Unfortunately, no. Here’s why oiling is non-negotiable:

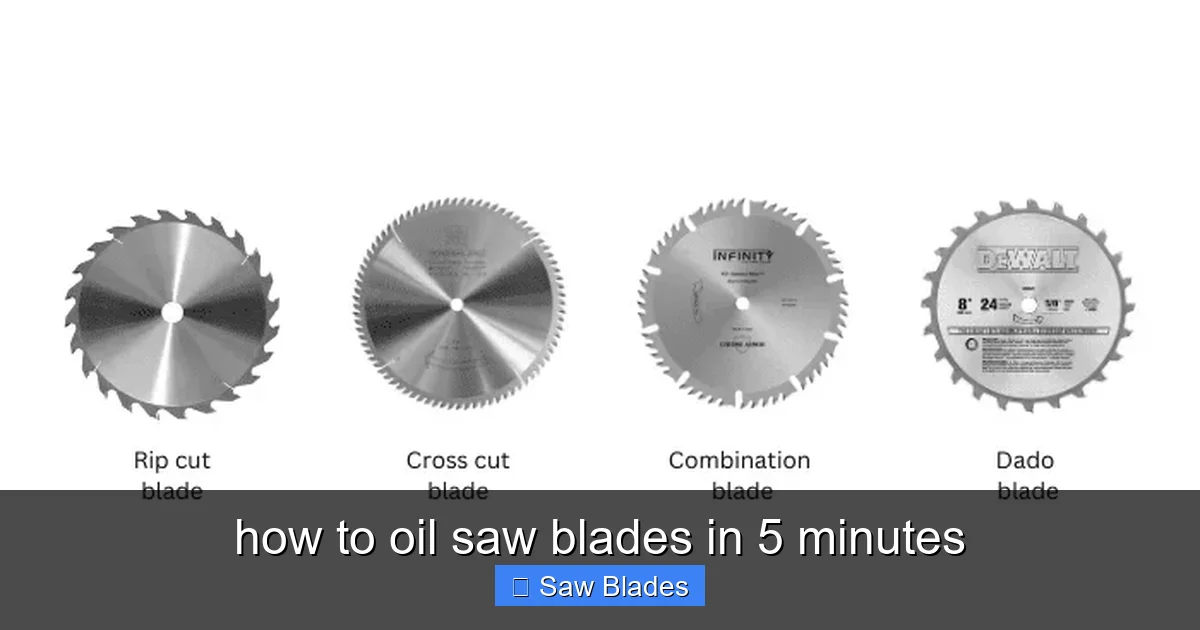

Visual guide about how to oil saw blades in 5 minutes

Image source: diywoodenplans.com

- Rust is a silent killer: Iron in steel blades reacts with oxygen and moisture, forming rust. Even tiny spots ruin cutting precision.

- Friction wears blades down: Dry blades create more heat and resistance when cutting, accelerating dulling.

- Sawdust sticks like glue: Without oil, fine particles cling to the blade, gumming up the teeth over time.

Oiling creates a micro-thin protective layer that:

- Blocks moisture from contacting the metal

- Lubricates the blade’s surface for smoother cuts

- Prevents sawdust from bonding to the steel

Neglecting this step means you’re essentially leaving your blade exposed to decay. A 5-minute oiling session after every use pays for itself in extended blade life – often doubling or tripling how long your blades stay sharp. For band saw users, this is especially critical; check out our guide on how to sharpen band saw blades to complement your oiling routine.

What You’ll Need (Just 3 Simple Items)

Don’t worry – you won’t need a toolbox full of supplies. Gather these basics:

Visual guide about how to oil saw blades in 5 minutes

Image source: jewelrysupply.com

- Blade oil or machine oil: Use 3-in-1 oil, bar chain oil, or dedicated saw blade oil. Never use vegetable or cooking oil – it turns sticky and attracts dirt.

- Clean microfiber cloth or paper towels: Avoid rough fabrics that could scratch the blade.

- Safety gear: Cut-resistant gloves and safety glasses (blades are sharp even when off!).

Optional but helpful:

- A soft-bristle brush (toothbrush works) for cleaning stubborn sawdust

- A blade storage case or sleeve

Pro tip: Keep your oil and cloth in your workshop so you never skip this step. For circular saw users, storing your tool properly is part of the process – learn how in our circular saw storage guide.

Step 1: Prep Your Blade (1 Minute)

Safety and cleanliness come first. Rushing this step risks injury or ineffective oiling.

Visual guide about how to oil saw blades in 5 minutes

Image source: dbsupply.com

Power Down & Remove the Blade

Unplug your saw or remove the battery. For table saws or miter saws, follow your manual’s blade removal process. If you’re unsure, our guide on changing circular saw blades covers the basics. Place the blade on a stable surface like a workbench – never hold it in your hand while oiling.

Wipe Off Loose Sawdust

Use a dry cloth to remove surface debris. Focus on the teeth and gullets (the spaces between teeth). If sawdust is caked on, gently brush it away with a soft-bristle tool. Never use compressed air – it can force dust into crevices or blow it into your eyes.

Step 2: Apply the Oil (2 Minutes)

This is where the magic happens. Apply oil evenly but sparingly – too much attracts dirt.

Shake & Dab, Don’t Soak

Shake your oil can well. Dip a corner of your cloth into the oil (or apply 1-2 drops directly to the cloth). You want it damp, not dripping. Excess oil creates a sticky mess that traps sawdust.

Coat the Entire Blade Surface

Starting at the center, wipe the oil along the blade’s flat sides in smooth, even strokes. Pay special attention to:

- The cutting edges (teeth)

- The gullets

- The arbor hole area

Rotate the blade as you go to cover all surfaces. For band saw blades, run the cloth along the entire length. For circular blades, work in sections. Pro tip: Use the cloth’s edge to get into tight gullets.

Step 3: Wipe Off Excess (1 Minute)

This step is crucial – leftover oil becomes gummy over time.

Buff to a Shine

Take a clean, dry section of your cloth and firmly wipe the blade. You should see a faint, even sheen – not wet spots or streaks. If the cloth picks up oil, switch to a fresh section. The goal is a barely-there protective layer, not a slick surface.

Check for Missed Spots

Hold the blade under good light. Look for dry patches (especially near the teeth) and lightly re-oil those areas. Wipe again immediately.

Step 4: Store Properly (1 Minute)

Oiling is wasted if you store the blade carelessly.

Use a Protective Cover

Place the blade in its original case, a blade sleeve, or wrap it in oilcloth. Avoid cardboard – it absorbs moisture. For table saws, store the blade on a dedicated rack away from humidity.

Keep It Dry & Cool

Store blades in a low-humidity area like a tool cabinet. Never leave them on concrete floors (which draw moisture) or in garages with temperature swings. If you use a reciprocating saw, proper storage prevents rust on those hard-to-reach blades too.

Troubleshooting Common Oiling Problems

Even with the best intentions, issues can pop up. Here’s how to fix them:

Sticky Residue on Blade

Cause: Too much oil or using the wrong type (like vegetable oil).

Fix: Wipe thoroughly with a cloth dampened with mineral spirits. Re-oil with the correct oil next time. Always use sparing amounts.

Rust Spots Appearing Anyway

Cause: Inconsistent oiling or high-humidity storage.

Fix: Sand rust spots lightly with fine steel wool, then re-oil. Store blades with silica gel packs to absorb moisture. Oil more frequently if you live in a humid climate.

Oil Not Staying on Blade

Cause: Blade wasn’t cleaned properly before oiling.

Fix: Always remove all sawdust first. Oil won’t adhere to dirty surfaces. Repeat the cleaning step if needed.

How Often Should You Oil Saw Blades?

The golden rule: Oil after every use. If you’re using a blade multiple times in one day, oil it at the end of the session. For long-term storage (more than a week), oil it before putting it away and check it monthly. Blades used in wet conditions (like cutting pressure-treated wood) need oiling immediately after use. Make this part of your routine – it takes less time than wiping down your saw!

Why This 5-Minute Habit Transforms Your Workflow

Oiling saw blades isn’t just about preventing rust – it’s about respecting your tools and your time. A well-maintained blade:

- Cuts faster with less effort

- Produces cleaner edges (no burning or tear-out)

- Reduces strain on your saw’s motor

- Saves you hundreds in replacement costs over time

Imagine finishing a project and knowing your blades are ready for the next job, no surprises. That’s the peace of mind this simple habit delivers. Plus, when it’s time to sharpen, you’ll get better results because the blade isn’t pitted with rust. For band saw users, this complements sharpening perfectly – a clean, oiled blade takes a sharper edge.

Conclusion: Your Blades Deserve 5 Minutes

Oiling saw blades is the ultimate “work smarter, not harder” practice. In just five minutes – less time than scrolling through social media – you protect your investment, ensure precision cuts, and avoid frustrating mid-project blade failures. Remember: clean the blade, apply oil sparingly, wipe off excess, and store it right. Do this consistently, and you’ll notice the difference in every cut. Your saw will run smoother, your projects will look better, and your wallet will thank you. So next time you finish a cut, grab that oil can. Your blades (and your future self) will appreciate it. Ready to tackle your next project? Keep your tools in top shape with our full range of maintenance guides.

🎥 Related Video: How to Clean a Circular Saw Blade- Guide

📺 Mellowpine Woodworking

Quick Tutorial on how to safely clean your circular saw blade.