Proper cordless drill motor care can double your tool’s lifespan and save you money. This guide covers ten simple yet effective maintenance strategies that every DIYer and professional should know. You’ll learn how to clean, lubricate, and store your drill correctly while avoiding common mistakes that damage motors.

Key Takeaways

- Clean regularly: Remove dust and debris after each use to prevent motor damage and overheating.

- Lubricate moving parts: Apply light oil to chuck and gears quarterly to reduce friction and wear.

- Store batteries smart: Keep batteries at 50% charge in cool, dry places to maintain power and protect the motor from voltage drops.

- Prevent overheating: Take breaks during heavy use to avoid burning out your motor windings.

- Use correct settings: Match speed and torque to your material to prevent motor strain.

- Check carbon brushes: Inspect brushes every 6 months and replace them before they wear completely.

- Follow the manual: Your manufacturer’s guidelines are the best source for model-specific care instructions.

Introduction: Why Cordless Drill Motor Care Matters

Your cordless drill is probably one of the most versatile tools in your workshop. That compact motor powers through wood, metal, and concrete with ease. But like any hardworking machine, it needs regular care to keep performing at its best. Many DIYers treat their drills rough—dropping them, ignoring strange noises, or running them until they smoke. This abuse cuts tool life in half and leads to expensive replacements.

Good cordless drill motor care isn’t complicated or time-consuming. Most tips take just a few minutes but deliver years of reliable service. Whether you own a premium model or a budget drill, these ten essential tips will help you maximize your investment. You’ll learn practical maintenance steps, storage solutions, and warning signs that indicate trouble. Let’s dive in and keep your drill running like new.

If you’re shopping for a new drill, check out our guide to the best cordless drill options on the market today.

Tip 1: Clean Your Drill After Every Use

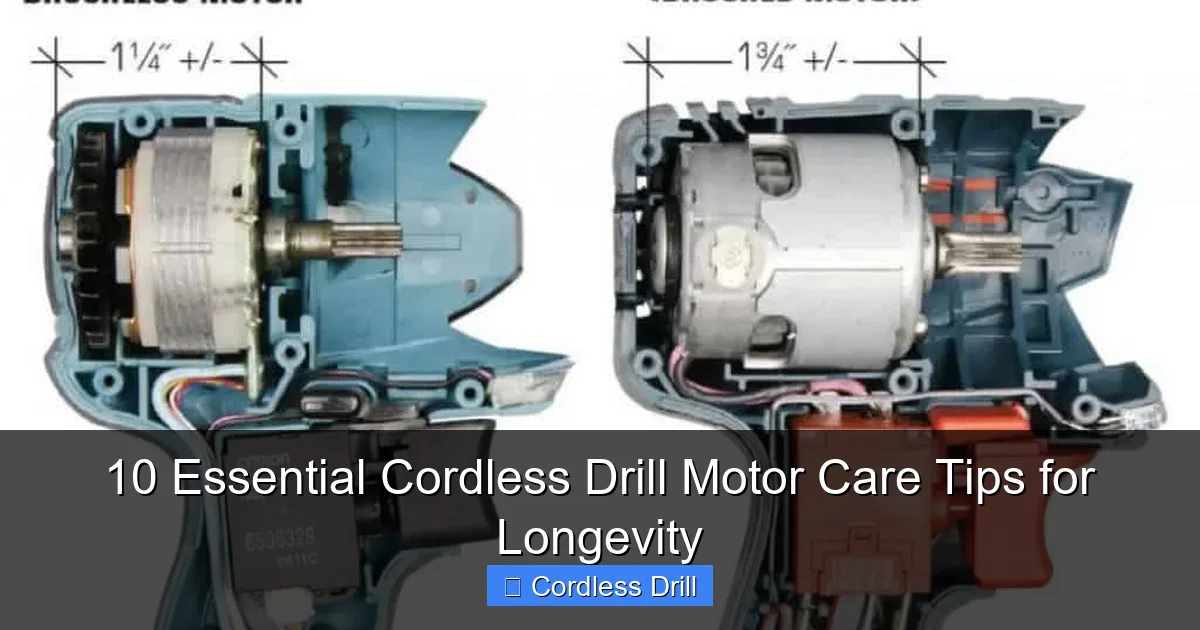

Dirt and dust are your motor’s worst enemies. They clog air vents, trap heat, and cause premature wear. Cleaning your drill takes less than five minutes but prevents 80% of common motor problems.

Visual guide about 10 Essential Cordless Drill Motor Care Tips for Longevity

Image source: mechanicwiz.com

How to Clean Your Drill Properly

Start by removing the battery. This is crucial for safety. Use a soft brush to gently sweep away dust from the vents, chuck, and motor housing. A toothbrush works perfectly for tight spaces. Never use water or household cleaners—they can damage electrical components.

For stubborn grime, use compressed air. Hold the can upright and spray in short bursts. Keep the nozzle at least six inches away from the drill. This blows debris out of vents without pushing it deeper inside. Wipe the housing with a slightly damp cloth, then dry thoroughly before reassembling.

Avoid pressure washers or hoses. Water intrusion causes immediate damage to motor windings and bearings. Also, don’t use solvents like brake cleaner or acetone. These strip protective coatings and degrade plastic parts.

Frequency Matters

Clean your drill after every project. Heavy use in woodworking creates sawdust that acts like sandpaper inside your motor. Metalworking produces fine particles that conduct electricity and cause short circuits. Even drywall dust can destroy a motor within months.

Set a reminder on your phone or make it part of your post-project routine. Five minutes of cleaning today prevents hours of frustration tomorrow.

Tip 2: Lubricate Moving Parts Quarterly

Friction creates heat. Heat wears out motor bearings and reduces efficiency. Proper lubrication keeps everything running smoothly and quietly.

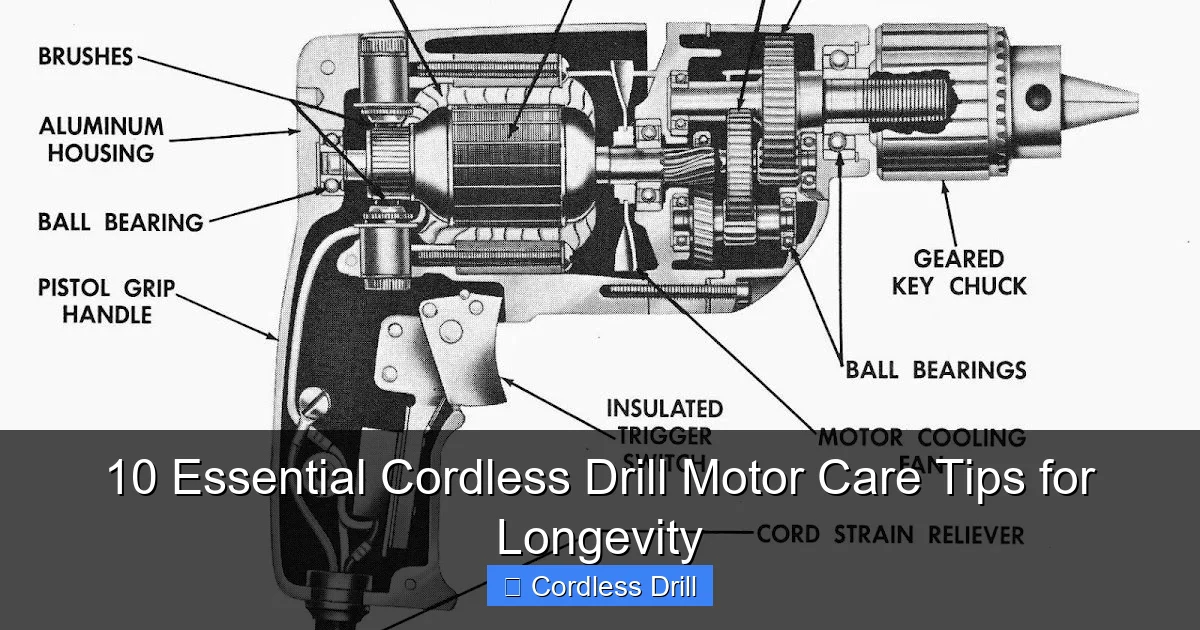

Visual guide about 10 Essential Cordless Drill Motor Care Tips for Longevity

Image source: i.ytimg.com

What Needs Lubrication

Focus on three main areas: the chuck mechanism, gear housing, and motor bearings. The chuck is the most obvious—apply a drop of light machine oil to the threads where it rotates. Open and close the chuck several times to work the oil in.

For gear housings, use a grease designed for power tools. Many drills have sealed gearboxes that don’t require regular maintenance, but older models need fresh grease every year. Check your manual to see if your model has grease fittings.

Motor bearings are usually sealed and don’t need oil. If your drill makes a grinding noise, the bearings may be failing. In this case, lubrication won’t help—replace the motor or drill.

Choosing the Right Lubricant

Never use WD-40 as a lubricant. It’s a solvent and water displacer, not a long-term lubricant. Instead, use 3-in-1 oil for light applications or synthetic power tool grease for gears. These products resist heat and don’t break down over time.

Apply lubricant sparingly. Too much oil attracts dust and creates a sticky mess. A little goes a long way—just a drop or two on each moving part.

Tip 3: Store Batteries at the Right Charge Level

Battery health directly affects motor performance. A weak battery forces your motor to work harder, generating excess heat and stress. Proper storage keeps batteries fresh and motors happy.

Visual guide about 10 Essential Cordless Drill Motor Care Tips for Longevity

Image source: i.pinimg.com

The 50% Rule

Store lithium-ion batteries at 50% charge. This is the sweet spot that minimizes chemical degradation. A fully charged battery puts pressure on its cells. A completely discharged battery can’t be revived. Fifty percent gives you the best of both worlds.

Before storing your drill for weeks or months, remove the battery and charge it to about halfway. Most chargers have a fuel gauge that shows charge level. If yours doesn’t, estimate by charging for half the normal time.

Temperature Control

Heat destroys batteries. Store them in a cool, dry place between 50-77°F (10-25°C). Never leave batteries in your truck during summer or in an unheated garage during winter. Extreme cold makes batteries lose power quickly. Extreme heat causes permanent damage.

Keep batteries away from metal objects like nails or tools. Contact between terminals can cause short circuits, fires, or explosions. Use the original case or a dedicated battery organizer.

Tip 4: Prevent Motor Overheating

Overheating is the number one cause of motor failure. When windings overheat, insulation melts and wires short out. This is permanent damage that can’t be repaired.

Recognize the Warning Signs

Your drill will tell you when it’s too hot. You’ll smell burning insulation—a sharp, unpleasant odor. The housing will feel too hot to hold comfortably. Performance will drop as the motor struggles to maintain speed.

If you notice any of these signs, stop immediately. Remove the battery and let the drill cool for at least 30 minutes. Continuing to use an overheated motor guarantees failure.

How to Keep Your Drill Cool

Take breaks during heavy drilling sessions. For every five minutes of continuous use, rest for one minute. This gives the motor time to dissipate heat through its vents.

Use the correct speed for your task. High speed generates more heat. When drilling large holes or driving long screws, use lower speeds. This reduces motor load and keeps temperatures down.

Ensure vents stay clear. Blocked vents trap heat inside. Hold your drill up to a light and look through the vents. You should see light passing through. If not, clean them with compressed air.

Tip 5: Use the Correct Bits and Settings

Forcing your drill to do work it’s not designed for strains the motor. Using the wrong bit or setting turns your drill into a high-speed oven that burns itself out.

Match Bits to Material

Wood bits have sharp points and wide flutes. They cut quickly and clear chips efficiently. Using a wood bit on metal creates friction and heat. The bit dulls instantly and can snap, damaging your drill.

Metal bits are shorter and have tighter spirals. They cut slower but cleaner. Masonry bits have carbide tips that hammer as they rotate. Never use them on wood—they’ll tear through and overload your motor.

Invest in quality bits. Cheap bits dull fast and work harder, making your motor compensate. Sharp bits cut cleanly with less effort. This reduces motor strain and extends battery life.

Master Your Speed and Torque Settings

Most cordless drills have two-speed ranges and adjustable torque. Low speed (0-500 RPM) is for driving screws and drilling large holes. High speed (500-1500 RPM) is for drilling small holes in metal and plastic.

Torque settings limit how much force the motor applies. Start low and increase as needed. When the clutch engages and the motor stops driving, you’ve reached the right setting. This prevents stripping screws and straining the motor.

Understanding these settings prevents motor overload. If you’re unsure which setting to use, consult our guide on what is the difference between impact driver and hammer drill to choose the right tool for your job.

Tip 6: Check and Replace Carbon Brushes

Carbon brushes conduct electricity to your motor’s rotating parts. They wear down over time and eventually need replacement. Ignoring them leads to sparking, poor performance, and motor failure.

Locate Your Brushes

Most cordless drills have brushes accessible through small ports on the motor housing. Look for rubber plugs or small covers near the back of the drill. Some models require removing the housing to access brushes.

Check your manual for exact locations. If you can’t find brushes, your drill may have brushless motor technology. Brushless drills last longer and require less maintenance. You’ll know you have brushes if your drill makes a slight squealing noise or shows sparks during use.

Inspection and Replacement

Inspect brushes every six months or after 100 hours of use. Remove the brush holder and slide out the carbon block. If it’s shorter than a quarter-inch, replace it immediately. Worn brushes create poor electrical contact, making your motor work harder.

Buy manufacturer-approved replacements. Generic brushes may fit but often wear faster or damage commutators. Replacement takes minutes—simply slide the new brush into place and reassemble.

While you’re inspecting brushes, check the commutator for grooves or burns. Minor imperfections can be cleaned with fine sandpaper. Deep grooves mean the motor needs professional service.

Tip 7: Keep Air Vents Clear

Air vents are your motor’s cooling system. Blocked vents cause overheating and catastrophic failure. They need as much attention as any other part of your drill.

Why Vents Get Blocked

Sawdust, drywall mud, and metal shavings love to collect in vents. They enter through the intake and get trapped by heat and static electricity. Over time, this creates a solid block that prevents airflow.

Some users store drills in toolboxes without ventilation. This traps heat and moisture, creating the perfect environment for corrosion. Always store your drill in an open case or on a wall mount where air can circulate.

Maintaining Clear Vents

Inspect vents weekly if you use your drill daily. Look for buildup at the openings. Use a toothpick or small brush to gently remove debris from the slots. Be careful not to push material deeper inside.

Compressed air is your best friend. Blow air through vents from both directions to dislodge hidden debris. Do this outdoors to avoid creating a dust cloud in your workspace.

Consider adding a filter. Some users attach a small foam filter over intake vents using double-sided tape. This catches large particles while allowing air to flow. Replace the filter monthly or when it looks dirty.

Tip 8: Handle Your Drill with Care

Drops and impacts damage motors internally. Bearings get knocked out of alignment. Shafts bend. Electrical connections break. Treat your drill like the precision instrument it is.

Proper Grip and Technique

Always grip your drill with both hands when possible. One hand on the handle, one supporting the battery pack. This gives you control and prevents accidental drops.

Apply steady, straight pressure when drilling. Angling the drill creates side load on the motor shaft. This wears bearings unevenly and can cause wobble. Let the bit do the cutting—don’t force it.

When driving screws, keep the drill perpendicular to the surface. Angled driving puts stress on the motor and gearbox. It also strips screw heads and damages your work.

Transportation and Storage

Never carry your drill by the battery pack. This strains the connection points and can break wires. Use the handle or a dedicated carrying case with foam inserts that cushion the tool.

When climbing ladders or working at heights, secure your drill with a tether. A falling drill can injure someone below and damage the tool on impact. Many drills have tether attachment points—use them.

Store your drill in a clean, dry place. A tool chest with individual compartments prevents scratches and impacts. Avoid stacking heavy tools on top of your drill.

Tip 9: Perform Regular Visual Inspections

Catching problems early saves money and time. A five-minute inspection every month can identify issues before they become expensive repairs.

What to Look For

Check the power cord on corded models for frays or exposed wires. For cordless drills, inspect the battery terminals for corrosion. Clean corroded terminals with a cotton swab and rubbing alcohol.

Look at the chuck for cracks or excessive wear. A damaged chuck can’t hold bits securely, causing slippage and motor strain. Spin the chuck by hand—it should rotate smoothly without wobbling or grinding.

Examine the housing for cracks, especially around the motor mount. Cracks allow dust inside and weaken the tool’s structure. If you find a crack, stop using the drill immediately.

Test Functionality

Run your drill without a bit for 30 seconds. Listen for unusual noises like grinding, squealing, or rattling. These indicate bearing failure or loose parts. Smell for burning odors that suggest electrical problems.

Test both speed settings and the reversing function. If the drill hesitates or doesn’t change direction smoothly, there’s an electrical issue that needs attention.

Check the trigger’s variable speed control. It should respond smoothly from zero to full speed. If it’s jumpy or unresponsive, the trigger switch may be failing.

Tip 10: Follow Manufacturer Guidelines

Your drill’s manual is the ultimate authority on maintenance. Manufacturers test their tools extensively and know exactly what they need. Ignoring the manual voids warranties and often leads to damage.

Read the Manual

Take 15 minutes to read your manual cover to cover. Pay special attention to the maintenance section. It lists specific lubricants, inspection intervals, and parts that need regular service.

Manuals often include exploded diagrams that show exactly how to disassemble your drill for cleaning. This is invaluable for DIY maintenance. If you lost your manual, download it from the manufacturer’s website using your model number.

Warranty Considerations

Using non-approved parts or lubricants can void your warranty. Stick to manufacturer-recommended products. If your drill needs professional service, use an authorized repair center. They use genuine parts and trained technicians.

Keep records of your maintenance. Some warranties require proof of regular care. A simple logbook with dates and tasks performed can save you thousands in repair costs.

When in doubt, call the manufacturer. They can answer specific questions about your model and clarify maintenance requirements. It’s better to ask than to guess and damage your tool.

Troubleshooting Common Motor Problems

Even with perfect care, problems can occur. Here’s how to diagnose and fix the most common motor issues.

Drill Won’t Start

If your drill doesn’t respond when you pull the trigger, check the battery first. Charge it fully and try again. If that doesn’t work, inspect the battery terminals for corrosion. Clean them with rubbing alcohol and a cotton swab.

The trigger switch might be faulty. Listen for a click when you pull the trigger. No click means the switch isn’t engaging. This requires professional repair or switch replacement.

Motor Runs Weak or Slow

Weak performance usually means a dying battery or worn brushes. Test with a fresh battery. If the problem persists, inspect the brushes as described in Tip 6.

Check for blocked vents. A clogged cooling system causes overheating, which reduces power output. Clean vents thoroughly and test again.

Unusual Noises

Grinding noises indicate bearing failure. The motor shaft may wobble when you move it side to side. Replace the motor or drill—bearing replacement is rarely cost-effective.

Squealing suggests dry or worn brushes. Inspect and replace brushes immediately. Continuing to use the drill will damage the commutator.

Sparking or Burning Smell

Stop using the drill immediately. Sparking means the motor is shorting out. This is a fire hazard and will cause complete failure. Remove the battery and let the drill cool completely.

Check for blocked vents and overheating. If the problem persists after cleaning, the motor is likely damaged beyond repair. Contact the manufacturer about replacement options.

Conclusion: Your Drill, Your Responsibility

Taking care of your cordless drill motor isn’t rocket science. It’s about consistency and attention to detail. Ten minutes of maintenance after each project pays dividends in years of reliable service. Your drill will run faster, last longer, and save you money.

Start with the basics: clean your drill, store batteries properly, and avoid overheating. These three steps prevent 90% of motor problems. Then add the other tips as habits. Soon you’ll be maintaining your drill without even thinking about it.

Remember, your drill is an investment. Treat it well and it will treat you well. For more expert advice and tool recommendations, explore our cordless drill resources page. Happy drilling!