This guide walks you through the complete history of the cordless drill, from its heavy beginnings to today’s smart tools. You’ll see how battery breakthroughs and motor tech made drills powerful and portable. Understanding this history helps you choose the right drill and appreciate the engineering in your hand.

Key Takeaways

- The First Attempts Were Cumbersome: Early cordless drills in the 1960s and 70s used bulky, weak nickel-cadmium batteries, making them heavy tools with limited appeal for professionals.

- Power Breakthroughs Drove Adoption: The introduction of Nickel-Metal Hydride (NiMH) and, crucially, Lithium-Ion (Li-ion) batteries revolutionized cordless tools by offering more power, longer runtimes, and lighter weight.

- It Sparked a DIY Revolution: As cordless drills became more affordable and capable in the 1990s and 2000s, they empowered homeowners to tackle projects themselves, changing the hardware and home improvement landscape.

- The Modern Ecosystem is Key: Today’s cordless drills are part of a broader system, with manufacturers building extensive platforms where one battery works with dozens of tools, from lights to lawn mowers.

- Smart Features Define the Future: Current drills integrate brushless motors for efficiency, smart electronics for control, and connected tech, pushing performance and user experience to new heights.

- Knowing History Informs Your Purchase: Understanding the evolution from voltage wars to battery chemistry helps you make smarter choices, like prioritizing a modern Li-ion system over older tech.

The Ultimate Cordless Drill History Guide You Need

Have you ever picked up your cordless drill and marveled at its power and freedom? That simple tool is the result of decades of innovation. Its history is a story of breaking free from the wall outlet. It’s a tale of engineering triumphs that changed how we build and repair our world.

This guide will take you on a journey from clunky beginnings to the sleek powerhouses we use today. You’ll learn about the key inventions and market shifts. By the end, you’ll not only know the history but also understand what makes a great modern drill. This knowledge can help you when you’re looking for the best cordless drill for your own projects.

Chapter 1: The Birth of an Idea (Pre-1960s)

Before the cordless drill, there was just the drill. Electric drills plugged into walls had been around since the early 20th century. They were powerful but tethered. Their reach was limited by the length of an extension cord. For tradespeople on construction sites or in large buildings, this was a major hassle. The dream of a portable, self-powered drilling tool was clear. The technology to make it practical, however, did not yet exist.

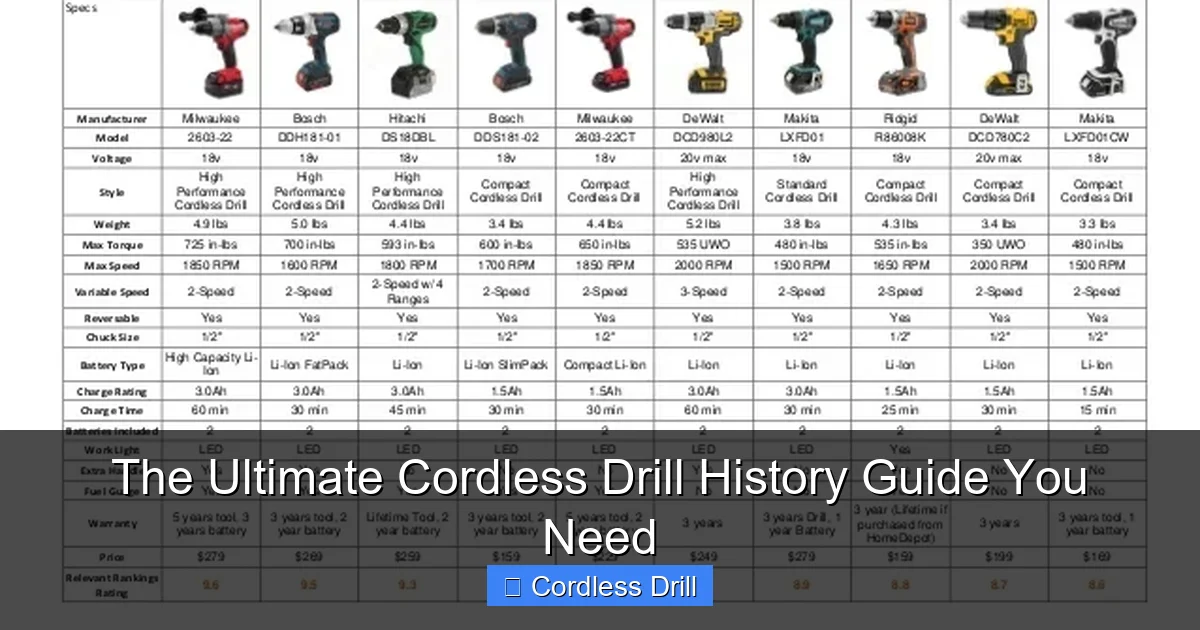

Visual guide about The Ultimate Cordless Drill History Guide You Need

Image source: ourhometools.com

The core challenge was the battery. Early lead-acid batteries (like in cars) were far too heavy and bulky. They couldn’t deliver the burst of power needed for drilling without being a burden. This era was all about the need. The market wanted freedom, and inventors began seeking a solution.

The Spark of Portability

Some of the earliest “portable” drills were actually pistol-grip tools with very long power cords. They highlighted the problem. Workers were constantly untangling cords or searching for outlets. This frustration set the stage. It created the perfect environment for a breakthrough. The race to create a viable cordless tool was on.

Chapter 2: The Heavyweight Pioneers (1960s-1970s)

The 1960s saw the first real commercial cordless drills. Companies like Black & Decker are often credited with these early models. What made them possible? The nickel-cadmium (NiCd) battery.

Visual guide about The Ultimate Cordless Drill History Guide You Need

Image source: i.ytimg.com

NiCd batteries were a step up from lead-acid. They were more energy-dense. But they were still far from perfect. These early cordless drills were notoriously heavy. The batteries were large and provided limited run time. Power, measured in voltage, was low—often 7.2V or 9.6V. They couldn’t handle demanding tasks like drilling into hard wood or masonry.

Limited Use and a Niche Market

Because of their weakness and weight, these first cordless drills were not taken seriously by most professionals. They were seen as novelties or light-duty tools. Their primary use was for simple screwdriving or drilling small holes in soft materials. They found a small niche but hadn’t yet revolutionized the trade. The tool was free from the cord, but still shackled by its own power source.

Chapter 3: The Power Surge (1980s-1990s)

The 1980s and 90s were a period of serious evolution. This is when the cordless drill began to shed its “toy” reputation. Two key battery technologies drove this change: Nickel-Metal Hydride (NiMH) and the game-changing Lithium-Ion (Li-ion).

Visual guide about The Ultimate Cordless Drill History Guide You Need

Image source: image.slidesharecdn.com

NiMH batteries arrived first. They offered a significant improvement over NiCd. They had higher capacity (longer run time) and were less prone to the “memory effect” that plagued NiCd cells. This made drills more reliable and useful for longer periods. Voltage ratings began to creep up, with 12V and 14.4V models becoming more common.

The Lithium-Ion Revolution

The real turning point was the adaptation of Lithium-Ion battery tech for power tools in the early 1990s (pioneered by companies like Makita). Li-ion batteries were a quantum leap. They were much lighter than NiCd or NiMH packs of the same power. They had higher energy density, meaning more runtime. They charged faster and had no memory effect.

This was the breakthrough the industry needed. Suddenly, an 18V cordless drill could be both powerful and reasonably lightweight. Professionals could finally consider going cordless for a majority of their tasks. The race for higher voltage and better battery life was officially on, leading to the powerful platforms we know today.

Chapter 4: Mainstream and the DIY Explosion (Late 1990s-2000s)

With Li-ion technology improving and costs gradually coming down, the cordless drill exploded into the mainstream. This coincided with a massive boom in do-it-yourself (DIY) home improvement. Television networks, magazines, and big-box hardware stores all promoted DIY culture. The cordless drill was its poster child.

For the weekend warrior, the appeal was undeniable. No more dragging out a heavy extension cord for a simple shelf project. No more risk of cutting the cord while working. The freedom was intoxicating. Brands marketed heavily to homeowners, offering compact, user-friendly kits. The cordless drill became a standard housewarming gift and a staple in home garages. If you’re new to using this versatile tool, check out our comprehensive guide on how to use a drill for screws into a wall to get started safely.

The Battery Platform Wars Begin

This era also saw the rise of the “tool platform” or “tool system.” Companies realized that if a homeowner bought a drill with a battery and charger, they’d likely stick with that brand for other tools. Thus, brands began expanding their cordless lines. The same 18V battery that powered your drill could now run a circular saw, a work light, or a leaf blower. This locked consumers into an ecosystem but provided incredible value and convenience. Choosing a drill became less about the single tool and more about committing to a brand’s entire family of tools.

Chapter 5: The Modern Marvel (2010s-Present)

Today’s cordless drills are feats of intelligent engineering. The competition is no longer just about raw power (though top-tier models boast incredible torque). It’s about efficiency, control, and connectivity.

The brushless motor is now standard in mid-range and professional drills. Unlike traditional brushed motors, brushless motors have no physical contacts that wear out. They are more efficient, converting more battery power into rotational force. This means more runtime, more power, and a longer tool life.

Smart Technology Integration

Modern drills are packed with electronics. They have variable speed triggers for precise control. They feature built-in LED work lights. Some have electronic clutches with multiple settings to prevent over-driving screws. High-end models even connect to smartphone apps. These apps can track tool usage, control settings, or lock the tool for security. The drill has become a “smart tool.”

Battery technology continues to advance. We now see compact but powerful batteries (like 12V MAX lines) that rival old 18V tools. And high-capacity batteries extend work time for the most demanding jobs. The focus is on a better user experience for every skill level. You can explore our full library of information on these modern tools in our cordless drill category.

Chapter 6: How This History Helps You Choose a Drill Today

Understanding this evolution isn’t just trivia. It gives you the wisdom to choose the right tool. Here’s how to apply the lessons of history.

- Prioritize Lithium-Ion (Li-ion): Never buy a new drill with an old NiCd battery. Insist on a modern Li-ion system. It’s lighter, more powerful, and has no memory effect.

- Think Ecosystem, Not Just Tool: Are you planning to buy more cordless tools? Consider the brand’s platform. Investing in a system now can save you money later.

- Voltage isn’t Everything: Early history was a voltage war. Today, motor efficiency (like brushless designs) matters more. A good 18V or 20V MAX brushless drill can outperform an older, less efficient 24V model.

- Match the Tool to Your Task: DIYers don’t need the most expensive pro model. A compact 12V drill is often perfect for household tasks. Professionals will want the durability and power of an 18V/20V MAX brushless platform. It’s also important to know the tool’s function; for instance, understand the difference between an impact driver and a hammer drill before you buy.

Troubleshooting Through a Historical Lens

Even modern drills can have issues. Viewing them historically can help diagnose problems.

Problem: Drill feels underpowered or dies quickly.

Historical Insight: This was the core flaw of early NiCd drills. For a modern tool, it likely means the battery is old and losing capacity (all batteries degrade) or you’re using a tool underpowered for the job (e.g., using a 12V drill for heavy framing).

Problem: Drill is excessively heavy and cumbersome.

Historical Insight: You might be using a high-capacity battery for a simple task. Just as early drills were overburdened, try a smaller, lighter battery from your system’s lineup if the job allows.

Problem: Confusion over tool type (Drill vs. Hammer Drill vs. Impact Driver).

Historical Insight: As cordless platforms grew, they specialized. A basic drill is for drilling holes and light screw driving. A hammer drill adds a pounding action for masonry. An impact driver is for high-torque screw driving. Knowing this evolution helps you pick the right specialist tool from your platform.

Conclusion: From Curiosity to Essential

The journey of the cordless drill is a perfect example of technology meeting human need. It grew from a clumsy, niche product into an indispensable tool that powers both global industries and weekend projects. Each era solved a critical problem: first portability, then power, then efficiency, and now intelligence.

When you pick up your cordless drill today, you’re holding over 60 years of incremental innovation. You’re holding the freedom that tradespeople in the 1950s could only dream of. By knowing its past, you can better harness its present power and wisely choose the tools that will build your future. Now, go drill something—cord-free.