Ladders are essential tools used in a variety of settings, from construction sites and warehouses to homes and offices. They are vital for reaching elevated areas, making tasks more efficient and accessible. However, not all ladders are created equal, and understanding how ladders are rated is crucial for selecting the right ladder for the job, ensuring safety, and preventing accidents.

1. Understanding Ladder Ratings: The Basics

Ladder ratings are classifications that provide information about the ladder’s strength, stability, and maximum load capacity. These ratings are important because they help users identify the ladder that suits their specific needs while ensuring it can safely handle the weight and stresses it will encounter during use.

The most common ladder ratings come from two organizations: the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA). These organizations set standards that manufacturers must follow to ensure that ladders are safe and reliable for users.

2. The Load Capacity Rating

Ladders are typically rated based on the weight they can support, which includes the weight of the user and any tools or materials they might carry. The weight capacity is essential because it helps prevent accidents caused by overloading the ladder.

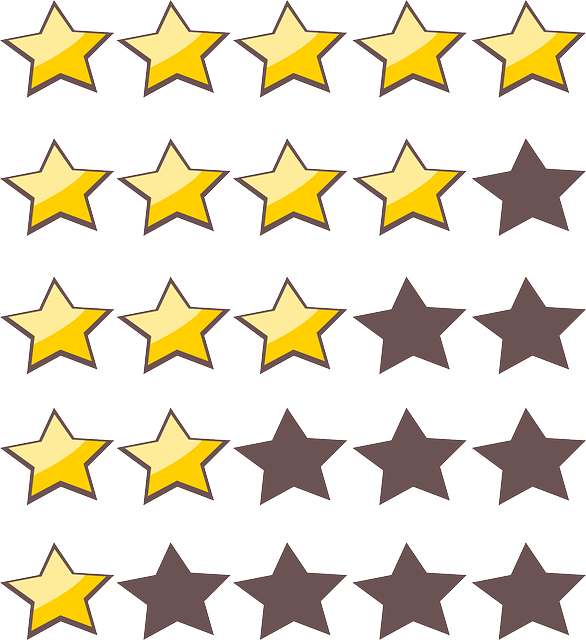

The load capacity is divided into different categories, each assigned a duty rating:

Type IAA (Extra Heavy Duty)

- Weight Capacity: 375 lbs (170 kg)

- Use: These ladders are designed for professionals who need heavy-duty equipment that can support a lot of weight. They are typically used for industrial or construction work where extra strength is needed.

Type IA (Heavy Duty)

- Weight Capacity: 300 lbs (136 kg)

- Use: These ladders are also used in demanding environments but can support slightly less weight than Type IAA ladders. They are ideal for jobs where stability and strength are critical.

Type I (Medium Duty)

- Weight Capacity: 250 lbs (113 kg)

- Use: Commonly used by contractors and maintenance workers. This type is suitable for most general tasks, such as painting or light repairs.

Type II (Light Duty)

- Weight Capacity: 225 lbs (102 kg)

- Use: Ideal for home use or light-duty tasks such as hanging pictures, changing light bulbs, or accessing attic spaces. This type is generally not suited for heavy lifting or long periods of use.

Type III (Household Duty)

- Weight Capacity: 200 lbs (91 kg)

- Use: Typically used for light, everyday household tasks. It is not recommended for commercial or industrial applications as it is not built for heavy workloads.

3. Material and Construction: Key Factors in Ladder Ratings

The material used in a ladder’s construction significantly influences its strength and durability. There are various types of materials used to build ladders, and each has specific features that affect the overall ladder rating.

Aluminum Ladders

- Advantages: Lightweight, corrosion-resistant, and easy to handle. These ladders are ideal for tasks that don’t require extreme weight-bearing capacity.

- Drawbacks: Aluminum ladders are not as sturdy as fiberglass ladders and may conduct electricity, posing a danger when working near power lines.

Fiberglass Ladders

- Advantages: Strong, durable, and non-conductive, making them a safer option for electrical work. Fiberglass ladders are also resistant to corrosion and typically last longer than aluminum.

- Drawbacks: Heavier than aluminum ladders, which can make them more cumbersome to transport.

Wooden Ladders

- Advantages: Traditional and sturdy, offering a solid foundation. They also do not conduct electricity.

- Drawbacks: Wooden ladders are heavier, less durable over time (especially if exposed to moisture), and generally not used in high-duty or industrial settings.

4. Height Rating: Understanding the Reach

The height rating of a ladder indicates how far the ladder can reach, not necessarily how tall the ladder is when extended. This rating is critical because it helps you understand the maximum height you can safely reach when using the ladder.

For example:

- A 6-foot ladder might give you a reach of around 10 feet, depending on your height and how you position the ladder.

- A 12-foot ladder can provide a reach of 16 feet or more.

While buying a ladder, it’s important to consider both your own height and the height you need to access when determining the right ladder size. Always follow the manufacturer’s guidelines on safe reach and positioning.

5. Safety Features: Extra Considerations in Ladder Ratings

While ladder ratings primarily focus on weight and height capacity, safety features are also a crucial aspect of ladder performance. Here are some additional elements to consider:

Slip-Resistant Feet

Ladders should have slip-resistant feet to ensure stability, particularly on smooth or wet surfaces. These feet are made from rubber or other non-slip materials that prevent the ladder from sliding during use.

Rungs and Steps

The design and spacing of the rungs or steps affect ladder safety and comfort. The rungs should be evenly spaced and wide enough to provide a secure grip, especially for individuals wearing gloves. Non-slip surfaces are also crucial to avoid slipping, particularly in outdoor or wet conditions.

Locking Mechanisms

For extension and multi-position ladders, ensure they have secure locking mechanisms to prevent accidental collapse while in use. These locks should engage firmly to ensure the ladder stays in place.

Stabilizers and Spreaders

Some ladders come with stabilizer bars or spreader braces to enhance safety and prevent the ladder from wobbling. These are especially important when working on uneven ground or in high-wind conditions.

6. OSHA and ANSI Standards: Compliance and Safety

When selecting a ladder, it is crucial to check whether it complies with the standards set by ANSI and OSHA.

ANSI Standards

The American National Standards Institute (ANSI) provides guidelines for ladder construction, materials, strength, and testing. ANSI sets the duty ratings for ladders, ensuring that they meet certain criteria for load capacity, durability, and safety.

OSHA Standards

The Occupational Safety and Health Administration (OSHA) is a regulatory body that ensures worker safety. OSHA sets guidelines on ladder use in the workplace, including specifications for ladder construction, maintenance, and safe use practices.

Both ANSI and OSHA standards play a crucial role in maintaining the safety of ladders and ensuring they are suitable for the intended job. When purchasing a ladder, always check for compliance labels from these organizations to verify the ladder’s safety.

7. How to Choose the Right Ladder

When selecting a ladder, keep the following factors in mind:

- Weight Capacity: Always choose a ladder that exceeds your weight, including any tools or materials you plan to carry.

- Height: Make sure the ladder is tall enough to reach your desired height without overreaching. This can prevent falls or accidents.

- Material: Choose the right material based on the environment where you’ll use the ladder. Fiberglass is ideal for electrical work, while aluminum is lighter for general use.

- Safety Features: Check for features like non-slip feet, secure rungs, and locking mechanisms to enhance stability.

8. Conclusion

Ladders are an essential part of many tasks, but it’s critical to understand how they are rated to ensure safe and efficient use. By considering the load capacity, materials, height ratings, safety features, and compliance with ANSI and OSHA standards, you can select the best ladder for your needs. Safety should always be the priority, so take the time to evaluate the specifications and choose a ladder that will meet the demands of the task while keeping you safe.

RELATED POST

- Essential Guidelines for Safe Climbing

- Get the Ladder in Animal Crossing

- Do You Unlock the Ladder in Animal Crossing

Recent Posts

Maintaining clean gutters is essential for preventing water damage to your home, and choosing the best ladder for cleaning gutters can make the job much easier and safer. With so many options on the...

Best Ladder for Cleaning Caravan Roof: Top Picks for You Every Adventure!

Today we will discuss the best ladder for cleaning caravan roof. Cleaning caravan roofs is one of the crucial tasks.After many days, a caravan roof can get dirty by debris, dirt, and grime. These can...