Ever wonder how fast your saw blade actually spins? This guide reveals surprising RPM ranges across different saw types – from slow-turning band saws to lightning-fast circular saws. Understanding blade speed is crucial for safety, cut quality, and tool longevity – we’ll show you exactly what to expect and why it matters for your next project.

Key Takeaways

- RPM varies wildly: Circular saws spin 3,500-6,000 RPM, while band saws crawl at 100-1,500 RPM – matching speed to material is non-negotiable.

- Speed = Cutting Power: Higher RPM generally means smoother cuts in wood, but metal-cutting blades need slower speeds to prevent overheating and premature wear.

- Safety first: Exceeding a blade’s max RPM rating risks catastrophic failure – always check the manufacturer’s label before cranking up the speed.

- Material dictates speed: Hardwoods and metals require slower RPM than softwoods or plastics; using the wrong speed ruins cuts and dulls blades fast.

- Measure accurately: Don’t guess! Use the RPM formula (RPM = (SFPM x 4) / Diameter) or consult your saw’s manual for precise settings.

- Listen to your saw: Unusual vibrations, burning smells, or excessive noise often signal incorrect blade speed – stop immediately and troubleshoot.

How Fast Saw Blades Spin: The Surprising Speed Revealed

You fire up your saw, hear that familiar whine, and push the trigger. But have you ever stopped to wonder: just how fast is that blade spinning? It’s not just trivia – understanding saw blade speed (measured in RPM, or Revolutions Per Minute) is fundamental to safe, efficient, and high-quality cutting. Whether you’re a weekend warrior tackling a deck project or a seasoned woodworker crafting fine furniture, knowing the RPM sweet spot for your blade and material can mean the difference between a perfect cut and a dangerous disaster.

This guide cuts through the confusion. We’ll reveal the surprising RPM ranges for all major saw types, explain why speed matters more than you think, show you how to measure and calculate it accurately, and give you practical tips to match blade speed to your material. Forget guesswork – by the end, you’ll know exactly how fast your saw blade should spin for any job. Let’s dive in!

Why Blade Speed Isn’t Just Noise – It’s Critical

Think blade speed is just about making the cut happen? Think again. RPM directly impacts three crucial things:

Visual guide about How Fast Saw Blades Spin The Surprising Speed Revealed

Image source: s3.amazonaws.com

- Cut Quality: Too fast? You get burn marks, rough edges, and splintering (especially on plywood). Too slow? The blade drags, causing tear-out and requiring excessive force. The right RPM delivers clean, smooth cuts with minimal sanding.

- Blade Life: Spinning a blade faster than its design allows generates intense heat. This softens the carbide teeth, accelerates wear, and can even warp the blade – turning your expensive blade into scrap metal in minutes. Slower speeds for hard materials keep teeth sharp longer.

- Safety: This is non-negotiable. Exceeding a blade’s maximum RPM rating is incredibly dangerous. The centrifugal force can cause the blade to shatter, sending shards flying at lethal speeds. Always respect the manufacturer’s speed limits!

Matching blade speed to the material you’re cutting isn’t optional – it’s the golden rule of saw operation. A blade designed for wood will destroy itself (and potentially you) if used at wood-cutting speeds on metal, and vice versa.

How Do We Measure Saw Blade Speed? RPM Demystified

RPM (Revolutions Per Minute) is the universal language of blade speed. It tells you how many full circles the blade makes in one minute. But how do you actually figure it out?

Visual guide about How Fast Saw Blades Spin The Surprising Speed Revealed

Image source: suaveyards.com

The Manufacturer’s Label: Your First Stop

Most quality saw blades have a clear label stamped on the blade plate (the flat center part). Look for:

- MAX RPM: The absolute maximum safe speed. NEVER exceed this number. This is your safety ceiling.

- Recommended RPM Range: Often listed as a range (e.g., 3,000 – 5,000 RPM). This is the optimal zone for performance and longevity.

- Diameter: The blade’s size in inches (e.g., 7-1/4″, 10″). Crucial for calculations.

Pro Tip: If the label is worn off, do not guess. Replace the blade or consult the manufacturer’s website using the blade model number. Safety isn’t worth risking over a worn label.

Calculating RPM: The SFPM Connection

Blade speed is also measured in Surface Feet Per Minute (SFPM) – the distance a point on the blade’s edge travels in one minute. This is especially important for industrial settings or when matching speeds across different blade sizes. The formula to convert SFPM to RPM is:

RPM = (SFPM x 4) / Blade Diameter (in inches)

Here’s how it works in practice:

- You have a 10-inch blade recommended for 12,000 SFPM.

- RPM = (12,000 x 4) / 10 = 48,000 / 10 = 4,800 RPM.

- So, your 10-inch blade should spin at 4,800 RPM for optimal cutting on that material.

Why the “4”? It’s a constant derived from pi (π ≈ 3.14) and unit conversions (feet to inches, minutes to seconds). You don’t need to memorize the math – just remember the formula!

Checking Your Saw’s Actual Speed

Your saw’s labeled RPM (e.g., “5,800 RPM no-load”) is its maximum no-load speed – how fast it spins with no blade attached and no material cutting. Once you add the blade and start cutting, the actual RPM will drop due to the load. To get a true reading:

- Use a Tachometer: A non-contact laser tachometer is the most accurate tool. Point it at a reflective mark on the blade arbor (the shaft the blade mounts on) while the saw is running under load (cutting material). This gives you real-world RPM.

- Listen and Feel: Experienced users learn to recognize the sound and vibration of a saw running at optimal speed vs. bogged down (too slow) or screaming (too fast). A healthy hum indicates good speed; a strained whine means it’s struggling.

Important: Always compare your measured or calculated RPM to the blade’s MAX RPM label. If your saw’s max no-load speed exceeds the blade’s max RPM, you must use a speed-reducing adapter or choose a different blade/saw combination. Never force it!

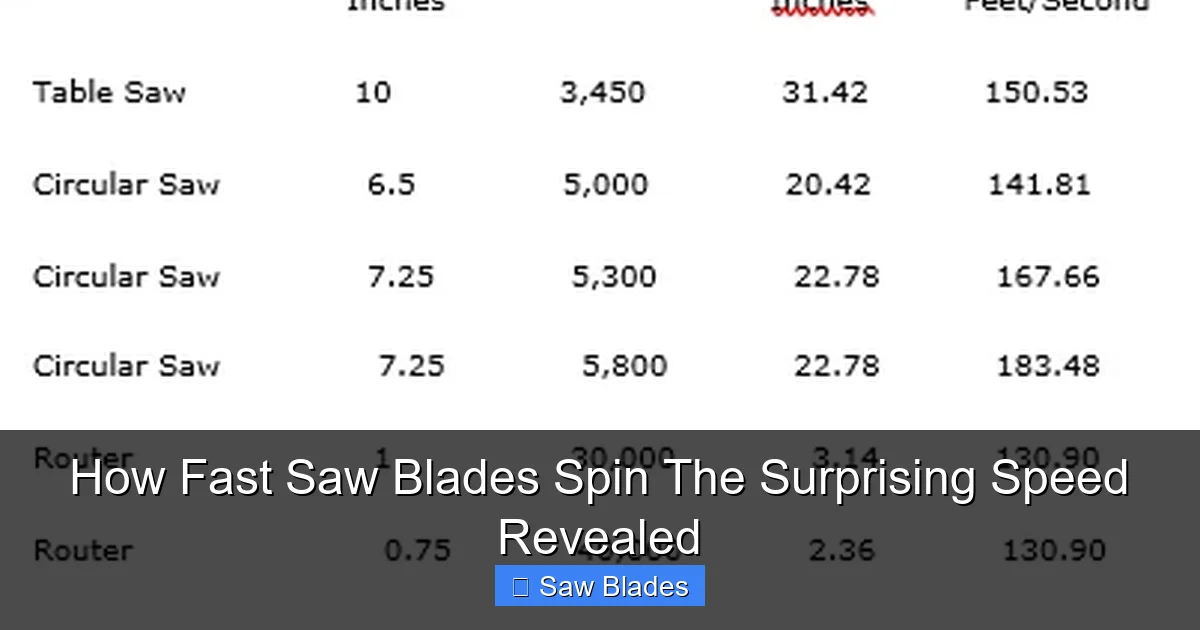

How Fast Do Different Saw Blades Spin? The RPM Breakdown

This is where it gets surprising! RPM ranges vary dramatically based on the saw type and its purpose. Let’s break down the most common saws:

Visual guide about How Fast Saw Blades Spin The Surprising Speed Revealed

Image source: hangar.flights

Circular Saws (Handheld & Worm Drive)

These workhorses are built for speed and portability.

- Typical RPM Range: 3,500 – 6,000+ RPM (No-Load)

- Why So Fast? High RPM allows the small diameter blades (typically 7-1/4″ or 8-1/4″) to achieve the necessary cutting speed (SFPM) for wood. The high tip speed creates a clean shear cut.

- Material Matters: Standard wood-cutting blades run near max RPM. Metal-cutting circular saw blades (often abrasive or specialized carbide) usually require significantly lower RPM (often 3,000-4,000 RPM max) to prevent overheating and blade disintegration. Always check the blade label! Need to swap blades? Learn how to change a blade on a circular saw safely before adjusting speed settings.

- Example: A common 7-1/4″ wood blade might have a max RPM of 5,800. A 7-1/4″ metal-cutting blade might have a max RPM of 3,850.

Table Saws

Stationary powerhouses offering precision and power.

- Typical RPM Range: 3,000 – 4,800 RPM (No-Load)

- Why Slower Than Circular Saws? Table saws use larger diameter blades (typically 10″). A larger blade traveling at the same tip speed (SFPM) as a smaller circular saw blade will have a lower RPM. This lower RPM provides more torque for heavy cuts and reduces the risk of kickback compared to ultra-high speeds.

- Material Matters: General-purpose wood blades run in the 3,400-4,000 RPM range. Dado blade stacks might run slightly lower. Diamond blades for concrete or masonry require much lower RPM (often 1,500-3,500 RPM max) – using a standard table saw motor speed would destroy them instantly. If you’re using a Ryobi table saw, ensure you know how to change the blade on a Ryobi table saw correctly to maintain safety specs.

- Example: A standard 10″ wood blade often has a max RPM of 4,000. A 10″ diamond blade for concrete might have a max RPM of 2,500.

Miter Saws (Compound & Sliding)

Designed for fast, accurate crosscuts.

- Typical RPM Range: 3,200 – 5,500 RPM (No-Load)

- Why This Range? They bridge the gap between circular saws (higher RPM, smaller blades) and table saws (lower RPM, larger blades). Sliding miter saws often run slightly slower than non-sliding models due to the added mass of the sliding mechanism.

- Material Matters: Wood-cutting blades run near max RPM. Metal-cutting miter saws (less common) use specialized blades with much lower max RPM ratings (similar to metal-cutting circular saw blades). Be cautious – some DIYers try to use wood blades on metal at high speed with disastrous results.

- Example: A common 10″ miter saw blade might have a max RPM of 4,800. A 10″ metal-cutting blade for a miter saw might have a max RPM of 3,200.

Band Saws (Wood & Metal)

The slow and steady specialists.

- Typical RPM Range: 100 – 1,500 RPM (No-Load) – Much slower than other saws!

- Why So Slow? Band saws use a continuous loop blade under tension. High speeds would cause excessive vibration, blade fatigue, and breakage. The slow speed provides control for intricate curves and resawing thick stock. Metal-cutting band saws run at the very low end of this range.

- Material Matters: Wood band saws have multiple speed settings (often 3-4). Softwoods use higher speeds (e.g., 1,200 RPM), hardwoods and resawing use medium speeds (e.g., 800 RPM), and cutting thick stock or metals use the slowest speeds (e.g., 200-400 RPM). Matching speed to material and blade width is critical. A dull blade struggles more – learn how to sharpen band saw blades to maintain optimal performance at the correct speed.

- Example: Cutting pine on a 1/2″ blade might use 1,000 RPM. Cutting steel on a 1/4″ blade might use 150 RPM.

Reciprocating Saws (“Sawzall”)

The aggressive demolition tool.

- Typical RPM Range: 0 – 3,000+ SPM (Strokes Per Minute) – Not RPM!

- The Key Difference: Reciprocating saws use a push-pull motion, not rotation. Speed is measured in SPM (Strokes Per Minute). While not RPM, the principle is similar – matching speed to the task.

- Why Variable Speed? Low SPM (500-1,500) provides control for precision cuts or cutting metal. High SPM (2,500-3,200) is for fast demolition in wood or drywall. The orbital action setting also affects effective cutting speed.

- Material Matters: Metal-cutting blades require lower SPM to prevent overheating and tooth stripping. Wood-cutting blades can handle higher SPM. Using the wrong speed burns out the motor or destroys the blade. Understanding how to use a reciprocating saw effectively includes selecting the right speed setting for the blade and material.

- Example: Cutting 2×4 studs: 2,800 SPM. Cutting a nail: 1,200 SPM.

Jigsaws

Versatile for curves and intricate cuts.

- Typical RPM Range: 0 – 3,000+ SPM (Strokes Per Minute)

- Similar to Reciprocators: Speed is SPM, not RPM. Variable speed control is essential for control.

- Material Matters: Delicate materials (plywood veneer, thin plastics) need low SPM to prevent chipping. Thick hardwoods can handle higher SPM. Blade type (fine-tooth vs. coarse) also interacts with speed.

- Example: Cutting thin plywood for inlays: 800 SPM. Cutting 1x pine: 2,500 SPM.

Safety First: The Non-Negotiable Rules of Blade Speed

Understanding RPM isn’t just about performance – it’s a critical safety issue. Ignoring speed limits is a leading cause of serious saw accidents.

- Respect the MAX RPM Label: This is the absolute limit set by the blade manufacturer based on the blade’s material, construction, and balance. Exceeding it risks the blade flying apart. Your saw’s speed MUST be equal to or less than the blade’s MAX RPM.

- Never Remove Blade Guards or Shields: These are designed to contain debris if a blade fails, even at correct speeds. They are your last line of defense.

- Use the Correct Blade for the Material: A wood blade on metal at wood-cutting speeds will catastrophically fail. A metal blade on wood at metal-cutting speeds will overheat and potentially warp or crack. Match the blade and the speed to the material.

- Inspect Blades Before Use: Look for cracks, missing teeth, warping, or excessive wear. A damaged blade is unpredictable, especially at high speeds. If you suspect a diamond blade is worn, check how to tell if a diamond saw blade is dull before pushing the speed.

- Secure Your Workpiece: A workpiece that moves or binds can cause kickback, which is amplified at high speeds. Use clamps and fences properly.

- Wear Proper Safety Gear: Safety glasses (ANSI Z87.1+) are mandatory. Hearing protection is essential at high RPMs. Consider a face shield for high-risk cuts.

Remember: If your saw is straining, vibrating excessively, making unusual noises, or smoking, STOP IMMEDIATELY. The most likely cause is incorrect blade speed or a damaged blade. Investigate before continuing.

Troubleshooting Common Speed-Related Problems

Even with the right blade and settings, issues can arise. Here’s how to diagnose speed problems:

Problem: Blade is Burning the Wood (Dark Marks, Smoke)

- Likely Cause: RPM too HIGH for the material/blade, or blade is DULL.

- Solution: Reduce saw speed if possible (some saws have dials). Ensure you’re using the correct blade for the wood type (e.g., fine-tooth for plywood). Check blade sharpness – replace if dull. Feed the material at a consistent, moderate pace; don’t force it.

Problem: Blade is Chattering, Vibrating Excessively, or Making a “Screaming” Noise

- Likely Cause: RPM too HIGH for the blade/material, blade is UNBALANCED or DAMAGED, or workpiece is not SECURE.

- Solution: Immediately reduce speed. Inspect blade for damage or missing teeth. Ensure blade is properly tightened and the arbor flange is clean. Double-check workpiece clamping. If vibration persists, the blade may be warped – replace it.

Problem: Saw is Bogging Down, Struggling to Cut, or Motor is Overheating

- Likely Cause: RPM too LOW for the material/blade, blade is DULL, or you’re FEEDING TOO FAST.

- Solution: Increase saw speed if possible (within blade’s max RPM). Check blade sharpness – replace if dull. Slow down your feed rate; let the blade cut at its own pace. Ensure you’re using the correct blade type (e.g., not a rip blade for crosscutting). Avoid cutting excessively thick material in one pass.

Problem: Blade is Dulling Extremely Fast

- Likely Cause: RPM too HIGH for the material (especially metal or hardwoods), using the WRONG BLADE for the material, or cutting ABRASIVE MATERIALS (like MDF or plywood with glue).

- Solution: Verify and adjust RPM to match material requirements. Use the correct blade (e.g., metal-cutting blade for metal, blade with more teeth for plywood). Consider using a blade specifically designed for abrasive materials if cutting them frequently. Ensure proper cutting technique (don’t force, maintain consistent feed).

Conclusion: Master Your Saw’s Speed for Better Results

So, how fast do saw blades spin? As we’ve discovered, the answer is far from simple. From the gentle 100 RPM crawl of a metal-cutting band saw to the blistering 6,000+ RPM scream of a circular saw, blade speed is a carefully engineered variable that makes or breaks your project. It’s not just about raw power; it’s about precision, safety, and respecting the physics of cutting.

The key takeaway is this: Never assume. Always check. Consult your blade’s label for the MAX RPM and recommended range. Match that speed to your material – softwoods and plastics tolerate higher speeds, while metals and hardwoods demand slower, more controlled rotation. Use the RPM formula if needed, and listen to your saw; it will tell you if something’s wrong.

By understanding and respecting blade speed, you transform from someone who just operates a saw into a confident craftsperson. You’ll achieve cleaner cuts, extend the life of your expensive blades, and, most importantly, keep yourself safe in the workshop. The next time you pull that trigger, you’ll know exactly why that blade is spinning at the speed it is – and you’ll have the knowledge to make it work perfectly for the task at hand. Now go cut with confidence!

🎥 Related Video: My brain can't process this speed 😵

📺 STORY SPIN

This vegetable slicer machine creates a mind-bending illusion where the blade appears slow, but its shocking high speed is …