Unlock the science behind every clean cut by understanding saw blade mechanics. You’ll learn how tooth design, material compatibility, and rotation speed transform raw power into precision cutting. Master blade selection and maintenance to boost efficiency and safety in all your projects.

Key Takeaways

- Tooth geometry is everything: The shape, angle, and spacing of teeth determine cutting speed, finish quality, and material compatibility.

- Match blades to materials: Using the wrong blade (e.g., wood blade on metal) causes overheating, poor cuts, and dangerous kickback.

- Blade types serve specific purposes: Circular, band, reciprocating, and jigsaw blades each have unique designs for their tools and tasks.

- Sharpness and maintenance are critical: Dull blades require excessive force, produce burn marks, and increase accident risk. Learn how to sharpen band saw blades properly.

- Safety starts with the right blade: Always inspect blades for damage, use correct RPMs, and wear protective gear.

- Tooth count affects cut quality: More teeth = smoother finish (ideal for plywood); fewer teeth = faster rough cuts (great for dimensional lumber).

How Saw Blades Work: Your Essential Cutting Guide

Ever wonder why some cuts glide through wood like butter while others leave splintered messes? The secret isn’t just your saw’s power—it’s the blade itself. Understanding how saw blades work transforms you from a casual DIYer into a confident craftsman. In this guide, you’ll discover the physics behind every clean cut, learn to choose the perfect blade for any material, and master maintenance to keep your tools safe and efficient. Whether you’re building a bookshelf or tackling metal fabrication, this knowledge is your ultimate edge.

The Cutting Edge: Basic Physics of Saw Blades

At its core, a saw blade converts rotational energy into linear cutting force. But there’s magic in the details. When your saw’s motor spins the blade, each tooth acts like a tiny chisel. As teeth engage the material, they:

Visual guide about How Saw Blades Work Your Essential Cutting Guide

Image source: img.freepik.com

- Shear fibers: Teeth slice through material fibers rather than crushing them

- Create kerf: The blade removes a thin strip (kerf) wider than the blade itself

- Eject waste: Gullets (spaces between teeth) carry away sawdust or chips

This process relies on three critical elements working together: tooth geometry, rotational speed, and feed rate (how fast you push the material). Get these out of sync, and you’ll get burning, chipping, or dangerous kickback.

Why Kerf Matters More Than You Think

Kerf isn’t just wasted material—it’s a design feature. A wider kerf (from thicker blades) reduces binding in deep cuts but removes more material. Thin-kerf blades (common on modern circular saws) conserve material and require less power. For precision work like cabinetry, a 1/8″ kerf blade is ideal. Rough framing? A 3/32″ kerf handles the abuse better.

Tooth Geometry: The Heart of Cutting Performance

If blades were cars, tooth geometry would be the engine. Four elements define how a blade behaves:

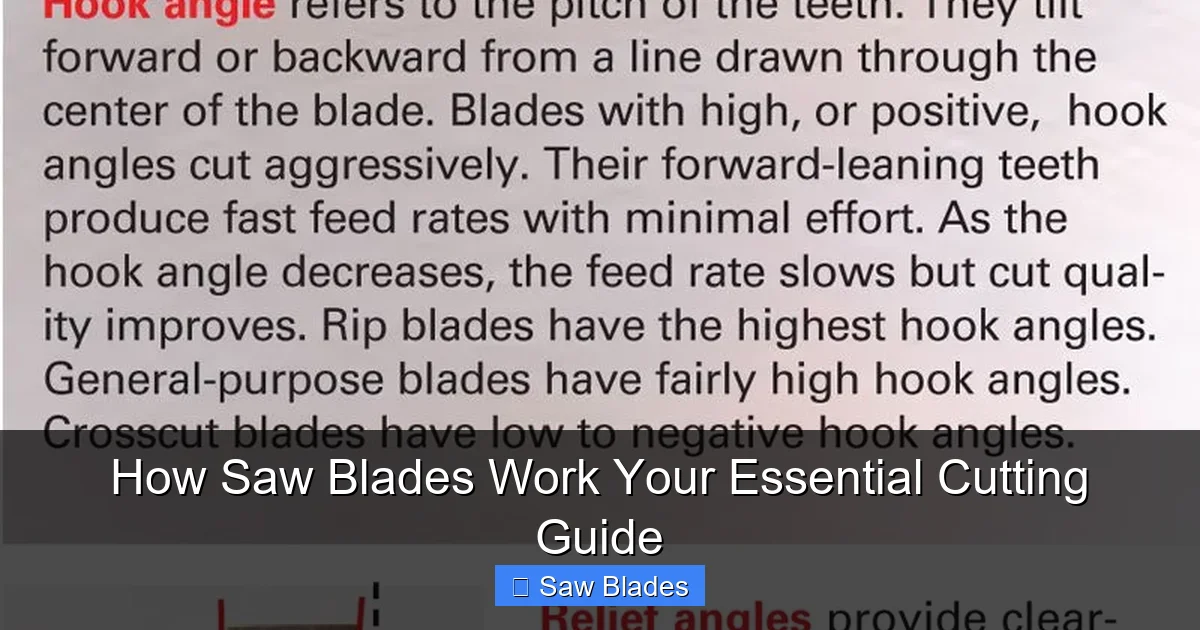

Visual guide about How Saw Blades Work Your Essential Cutting Guide

Image source: thumbs.dreamstime.com

1. Tooth Shape (Profile)

- Alternate Top Bevel (ATB): Teeth angled left/right for clean crosscuts in plywood. Creates a “scissor” action.

- Flat Top (FT): Straight-top teeth for aggressive rip cuts in solid wood. Plows through fibers.

- Triple Chip Grind (TCG): Alternating flat and pointed teeth for hard plastics and non-ferrous metals.

Pro Tip: For plywood, an 80-tooth ATB blade gives glass-smooth edges. For ripping 2x4s, switch to a 24-tooth FT blade.

2. Tooth Angle (Hook Angle)

This is the forward tilt of the tooth. High hook angles (15°+) pull material aggressively—great for rip cuts but risky for crosscuts. Low/negative hook angles (0° to -7°) resist grabbing, ideal for finish work. Miter saws typically use 0° to 5° for controlled crosscuts.

3. Tooth Spacing (Gullet Size)

Big gullets = fast chip removal (for thick wood). Small gullets = finer finishes (for thin materials). A framing blade has huge gullets; a laminate blade has tiny ones.

4. Tooth Count

More teeth = smoother cuts but slower feed rates. Fewer teeth = faster cuts but rougher finishes. Match tooth count to material thickness:

- Thin materials (1/4″): 60-100 teeth

- Medium materials (1″): 40-60 teeth

- Thick materials (2″+): 24-40 teeth

Blade Types Decoded: Matching the Tool to the Task

Not all blades are created equal. Using a wood blade on metal isn’t just inefficient—it’s dangerous. Here’s your cheat sheet:

Visual guide about How Saw Blades Work Your Essential Cutting Guide

Image source: i.pinimg.com

Circular Saw Blades

The workhorse of construction. Key features:

- Arbor size: 5/8″ or 1″ (match your saw’s arbor!)

- Diameter: 7-1/4″ most common for handheld saws

- Specialty types: Combination blades (40-50 teeth) handle both rip and crosscuts. For ultra-smooth plywood, use a dedicated 80-tooth blade.

When changing blades, always follow how to change blade on circular saw safety steps—never force a mismatched arbor!

Band Saw Blades

Continuous loop blades for curves and resawing. Critical factors:

- Width: Narrow (1/4″) for tight curves; wide (1″) for straight resawing

- Tooth pitch: Fine (14-18 TPI) for thin wood; coarse (3-6 TPI) for thick stock

- Material: Carbide-tipped for metal; carbon steel for wood

Proper tension prevents wandering. Learn how to sharpen band saw blades to extend blade life.

Reciprocating Saw Blades

Powerful demolition tools. Blade selection depends on:

- Material: Bi-metal for wood/metal; carbide grit for masonry

- Length: 4″-6″ for general use; 9″+ for deep cuts

- Tooth design: Wavy set for wood; straight set for metal

For plumbing work, how to use a reciprocating saw with a metal-cutting blade prevents pipe damage.

Jigsaw Blades

For intricate curves. Key specs:

- TPI (Teeth Per Inch): Higher TPI = smoother cuts

- Shank type: T-shank (most common) vs. U-shank

- Specialty blades: Down-cut for laminate (prevents top splintering)

Material Matters: Choosing the Right Blade

Using the wrong blade turns easy jobs into nightmares. Here’s how to match blades to materials:

Wood Cutting

- Softwood (Pine, Fir): Standard carbide-tipped blades. 24-40 teeth for framing.

- Hardwood (Oak, Maple): Higher-quality carbide with anti-friction coating. 60-80 teeth for clean cuts.

- Plywood/Laminate: Fine-tooth ATB blades (80+ teeth). Use masking tape to prevent tear-out.

Metal Cutting

- Ferrous metals (Steel): Abrasives (diamond or aluminum oxide) or bi-metal blades with low TPI (10-14).

- Non-ferrous (Aluminum, Copper): Carbide-tipped blades with high TPI (18-24) and triple-chip grind.

Warning: Never use wood blades on metal—they can shatter from heat buildup!

Specialty Materials

- Plastics: Fine-tooth blades with low hook angle to prevent melting.

- Masonry: Diamond-tipped or abrasive blades. Requires water cooling for concrete.

- Tile: Continuous rim diamond blades for clean cuts without chipping.

Blade Maintenance: Extending Life and Performance

A dull blade isn’t just frustrating—it’s a safety hazard. Signs you need maintenance:

- Burn marks on cut edges

- Excessive sawdust instead of chips

- Blade wanders from your cut line

- You need to push harder to cut

Cleaning Your Blades

Sap, pitch, and resin gunk up teeth. Soak blades in blade cleaner or oven cleaner for 15 minutes. Scrub gently with a toothbrush. Rinse and dry thoroughly—moisture causes rust.

Sharpening Basics

While professional sharpening is best for carbide, you can touch up carbon steel blades:

- Secure blade in a vise

- Use a triangular file for the face angle

- Maintain consistent pressure—don’t over-file!

- Check sharpness by cutting paper (should slice cleanly)

For band saws, learn how to sharpen band saw blades to avoid uneven wear.

Storage Solutions

Prevent nicks and rust:

- Use blade guards or cardboard sleeves

- Store vertically in a rack (not stacked)

- Apply light machine oil for long-term storage

Check out how to store circular saw blades safely in your workshop.

Troubleshooting Common Blade Problems

Even experts hit snags. Here’s how to fix them:

Problem: Burning or Smoking Cuts

Cause: Dull blade, wrong feed rate, or incorrect blade for material.

Solution: Slow your feed rate. Check blade sharpness. Ensure blade matches material (e.g., no wood blade on metal).

Problem: Blade Wandering or Kickback

Cause: Dull teeth, improper tooth set, or forcing the cut.

Solution: Replace blade. Use a guide rail for circular saws. Never push material sideways against the blade.

Problem: Chipped or Rough Edges

Cause: Blade too coarse for material, or cutting unsupported plywood.

Solution: Use higher TPI blade. Support both sides of cut with sacrificial boards.

Problem: Excessive Vibration

Cause: Warped blade, incorrect arbor size, or loose mounting.

Solution: Inspect blade for flatness. Ensure arbor nut is properly tightened (but not overtightened).

Conclusion: Master Your Cuts with Confidence

Understanding how saw blades work puts you in control of every project. Remember: the right tooth geometry transforms power into precision, matching blades to materials prevents disasters, and regular maintenance keeps your tools safe and efficient. Whether you’re slicing plywood for a DIY desk or cutting metal pipes, these principles ensure clean, accurate results. Keep this guide handy, respect your blades, and watch your craftsmanship soar. Now grab your saw—you’ve got cuts to make!

🎥 Related Video: Professional saw blades for sharpening saw blades #tools

📺 ToolDisplay