To optimize your water hammer arrestor installation, ensure proper sizing and placement. Regular maintenance and periodic inspections are crucial.

Water hammer arrestors prevent the loud banging noise in pipes caused by sudden water pressure changes. Proper installation is vital for effective performance and longevity. Choose the correct size based on your plumbing system’s specifications. Install the arrestor near the source of the water hammer for best results.

Regular maintenance helps in identifying potential issues early, ensuring the arrestor continues to function effectively. Periodic inspections can prevent damage to your plumbing system, saving you from costly repairs. By following these steps, you can ensure a quiet and efficient water system in your home.

Choosing The Right Location

Choosing the right location for your water hammer arrestor is crucial. Proper placement ensures efficiency and longevity. This guide will help you find the best spot.

Proximity To Problem Areas

Place the arrestor near the problem areas. This reduces water hammer effects. These areas include washing machines and dishwashers.

Check for noisy pipes. They indicate where the problem lies. Install the arrestor close to these spots.

Use a map of your plumbing system. Identify high-risk areas. This will help you choose the best location.

Accessibility For Maintenance

Ensure the arrestor is easy to reach. You may need to fix it later. Placing it in an accessible spot saves time.

Avoid hidden spots. These make maintenance hard. Choose open areas like basements or utility rooms.

Label the arrestor’s location. This helps during future inspections. You can find it quickly when needed.

| Consideration | Reason | Example Location |

|---|---|---|

| Proximity to Problem Areas | Reduces water hammer effects | Near washing machine |

| Accessibility for Maintenance | Easy to reach for repairs | Basement |

| Labeling | Quick identification | Utility room |

- Place arrestor near noisy pipes.

- Ensure easy access for maintenance.

- Label the arrestor’s location.

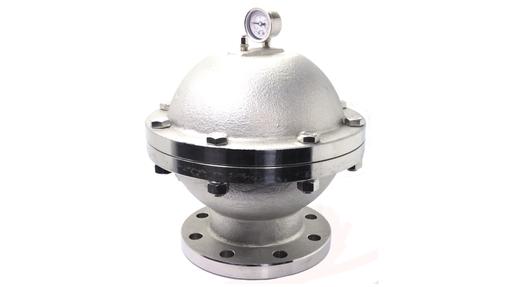

Credit: www.comeval.es

Correct Sizing Of Arrestors

Optimizing your water hammer arrestor installation starts with correct sizing. An improperly sized arrestor won’t stop water hammer. The system will still experience noise and damage.

Pipe Diameter Considerations

The diameter of your pipes matters. Larger pipes need larger arrestors. Measure the diameter of your pipes accurately. Use a caliper or a measuring tape. Refer to the manufacturer’s guidelines for sizing.

| Pipe Diameter (inches) | Recommended Arrestor Size |

|---|---|

| 1/2″ | Small |

| 3/4″ | Medium |

| 1″ | Large |

Flow Rate Calculations

Flow rate is also critical. Higher flow rates need larger arrestors. Calculate the flow rate in your system. Use the formula:

Flow Rate (GPM) = Pipe Area (sq. inches) x Velocity (inches/sec) x 0.3208

Ensure you know the velocity of the water. You can find this in system specifications. Match the flow rate to the arrestor capacity.

- Low Flow: Up to 5 GPM

- Medium Flow: 5-10 GPM

- High Flow: Over 10 GPM

Check the arrestor’s capacity rating. Select an arrestor that can handle your system’s flow rate.

Proper Mounting Techniques

Optimising your water hammer arrestor installation is crucial. It ensures the longevity and efficiency of the system. Proper mounting techniques play a vital role. They help in preventing damage and ensuring smooth operation. This section covers the best practices for mounting your water hammer arrestor.

Vertical Vs. Horizontal Installation

Understanding the orientation of your water hammer arrestor is important. Vertical installation is often preferred. It allows for better air cushioning. This can be ideal in many situations. However, horizontal installation may be necessary in tight spaces. Always follow the manufacturer’s guidelines. This ensures optimal performance regardless of orientation.

Secure Fastening Methods

Secure fastening is crucial for stability and efficiency. Use pipe clamps or brackets to hold the arrestor in place. Ensure the fasteners are tightly secured. This helps prevent vibrations and movements. You can use the following methods for secure fastening:

- Pipe Clamps: These are easy to install and adjust.

- Mounting Brackets: They provide extra support for heavy arrestors.

- Screws and Anchors: Use these for added stability in concrete or brick walls.

Each method has its own advantages. Choose the one that best suits your installation needs. Ensure the arrestor is firmly attached. This prevents any unwanted movements.

| Installation Method | Best For | Advantages |

|---|---|---|

| Vertical Installation | Standard setups | Better air cushioning |

| Horizontal Installation | Tight spaces | Space-saving |

| Pipe Clamps | General use | Easy to install |

| Mounting Brackets | Heavy arrestors | Extra support |

| Screws and Anchors | Concrete walls | Added stability |

Material Selection

Optimising your water hammer arrestor installation requires careful material selection. The materials you choose play a significant role in the system’s performance. Let’s explore the key factors to consider.

Durability Factors

Durability is crucial for the long-term efficiency of your water hammer arrestor. Some materials last longer than others. Stainless steel is highly durable and resists corrosion. Brass offers good durability and is also resistant to rust.

Consider the environmental factors. If the arrestor is exposed to harsh conditions, choose materials with high resistance. Plastic materials are less durable but can be suitable for low-pressure systems.

| Material | Durability | Best Use |

|---|---|---|

| Stainless Steel | High | High-pressure systems |

| Brass | Medium-High | Medium-pressure systems |

| Plastic | Low | Low-pressure systems |

Compatibility With Piping

Ensure the material of the water hammer arrestor matches your piping system. This prevents corrosion and ensures proper function. If you have copper pipes, brass or stainless steel arrestors are ideal. For PVC pipes, use plastic arrestors.

Match the material to avoid chemical reactions. Mismatched materials can lead to leaks and failures. Use the table below to guide your selection:

| Piping Material | Compatible Arrestor Material |

|---|---|

| Copper | Brass, Stainless Steel |

| PVC | Plastic |

| Galvanized Steel | Stainless Steel |

Choosing the right material ensures compatibility and system efficiency. Proper material selection extends the lifespan of your installation.

Regular Maintenance Practices

Regular maintenance practices ensure your water hammer arrestor performs optimally. This prevents potential plumbing issues. Here, we will discuss two key areas: inspection frequency and signs of wear and tear.

Inspection Frequency

Inspect your water hammer arrestor at least twice a year. This helps identify issues before they become serious. Create a checklist for each inspection. This ensures you don’t miss any steps. Your checklist might include:

- Checking for leaks

- Ensuring the device is securely attached

- Listening for unusual noises

- Verifying proper water flow

Signs Of Wear And Tear

Look for signs of wear and tear during inspections. These signs can indicate problems. Common signs include:

- Leaks around the device

- Water stains on walls or floors

- Unusual noises like banging or clanking

- Reduced water pressure

Address these issues immediately to prevent further damage. Use the following table to track common issues and solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| Leaks | Loose fittings | Tighten connections |

| Water stains | Internal leaks | Inspect and replace if necessary |

| Unusual noises | Air in the system | Bleed the system |

| Reduced pressure | Blockages | Clean the arrestor |

Regular maintenance keeps your water hammer arrestor in top shape. This ensures your plumbing system runs smoothly.

Pressure Management

Effective pressure management is crucial for optimising your water hammer arrestor installation. Proper pressure control ensures system longevity and reduces noise. Below, we’ll discuss key steps in managing pressure effectively.

Adjusting Pressure Regulators

Pressure regulators maintain consistent water flow. Adjusting them correctly is vital.

- Locate the pressure regulator valve.

- Turn the adjustment screw clockwise to increase pressure.

- Turn it counterclockwise to decrease pressure.

- Use a pressure gauge to monitor changes.

Ensure the pressure remains within the recommended range. High pressure can damage pipes. Low pressure can reduce water flow.

Monitoring System Pressure

Regular monitoring of system pressure ensures optimal performance.

- Install a pressure gauge at key points in your system.

- Check pressure readings periodically.

- Record these readings in a log for future reference.

High or low pressure readings can indicate underlying issues. Addressing these promptly prevents long-term damage.

| System Component | Recommended Pressure (psi) |

|---|---|

| Main Water Line | 60-80 |

| Secondary Lines | 50-70 |

Ensuring your system operates within these levels maximises efficiency.

Noise Reduction Strategies

Water hammer arrestors reduce noise caused by water pipes. Proper installation can further minimize noise. Here are some effective noise reduction strategies.

Using Insulation

Insulation helps in reducing noise from water pipes. Wrap the pipes with foam insulation sleeves. These sleeves absorb vibrations and reduce sound. Ensure the insulation material is high-quality and fits the pipes snugly.

Use insulation tape to secure the sleeves. This prevents them from slipping. Insulate all accessible pipes, especially in walls and ceilings.

| Insulation Material | Benefits |

|---|---|

| Foam Sleeves | Absorbs vibrations, easy to install |

| Insulation Tape | Secures sleeves, enhances insulation |

Positioning Away From Living Areas

Install the water hammer arrestor away from living areas. This reduces noise exposure in rooms where people gather. Place the arrestor in utility rooms or basements.

Follow these steps for better positioning:

- Identify the main water lines.

- Locate areas with minimal foot traffic.

- Install the arrestor in these quiet zones.

This strategy significantly reduces noise disturbance. Keep the arrestor accessible for maintenance.

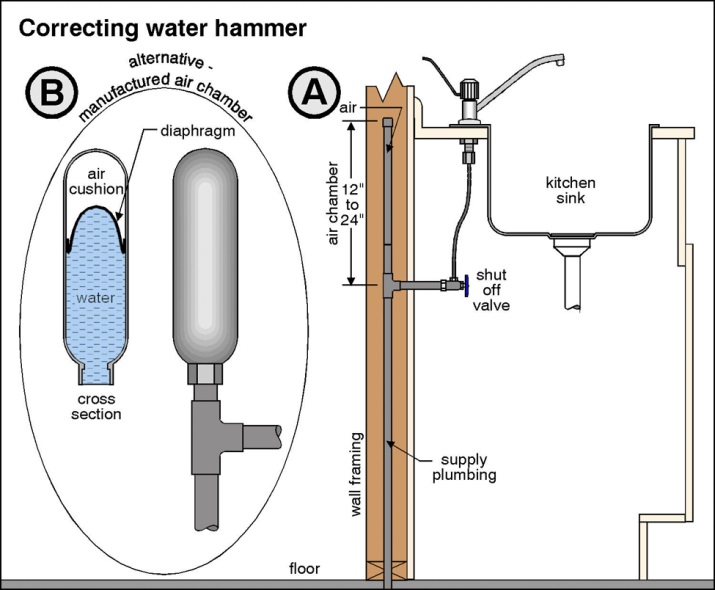

Credit: www.measuremonitorcontrol.com

Common Installation Mistakes

Installing a water hammer arrestor can prevent noisy pipes. Yet, many make common mistakes during installation. These errors can reduce efficiency and lifespan. Knowing these can help you avoid them.

Avoiding Oversizing

One common mistake is oversizing the water hammer arrestor. An oversized arrestor can cause issues. It may fail to absorb the shock properly. This can lead to noisy pipes and potential damage.

To avoid this mistake:

- Measure the pipe diameter accurately.

- Choose an arrestor that matches the pipe size.

- Consult manufacturer guidelines for the right size.

An arrestor that fits well works efficiently. This ensures smooth operation and long-term reliability.

Ensuring Proper Sealing

Another mistake is improper sealing during installation. A poor seal can cause leaks. This reduces the arrestor’s effectiveness and can cause water damage.

To ensure proper sealing:

- Clean the pipe ends thoroughly before installation.

- Use the right type of sealant for your pipes.

- Tighten the connections firmly but avoid over-tightening.

Follow these steps to ensure a leak-free installation. A proper seal keeps your system efficient and safe.

Credit: www.autographbook.net

Frequently Asked Questions

What Is A Water Hammer Arrestor?

A water hammer arrestor is a device that absorbs hydraulic shock, preventing damage to pipes and fixtures.

Why Is My Water Hammer Arrestor Not Working?

A clogged or improperly installed arrestor may fail. Check for debris or incorrect installation to solve the issue.

How Do I Install A Water Hammer Arrestor?

First, turn off the water supply. Then, attach the arrestor near the problematic valve or fixture.

Where Should I Place A Water Hammer Arrestor?

Install the arrestor close to the valve or fixture causing the noise. This ensures maximum effectiveness.

Can A Water Hammer Arrestor Fix Banging Pipes?

Yes, it absorbs hydraulic shock, reducing or eliminating the banging noise in your pipes.

Conclusion

Optimising your water hammer arrestor installation ensures longevity and efficiency. Follow these steps to avoid costly repairs. Proper installation and regular maintenance are key. A well-optimised system protects your plumbing and enhances performance. Implement these tips for a quieter, more reliable water system.

Your home’s plumbing will thank you.