Ensuring ladder safety is crucial in any workplace. OSHA has specific ladder inspection requirements to keep workers safe.

Ladders are common tools in many industries. But they also pose serious risks if not maintained properly. That’s where OSHA ladder inspection requirements come in. These guidelines help prevent accidents and injuries. Knowing these rules can protect both workers and employers.

In this blog, we will explore OSHA’s detailed inspection requirements. Understanding these can help you maintain safer work environments. So, let’s dive into what you need to know about inspecting ladders according to OSHA standards.

Introduction To Osha Ladder Regulations

The Occupational Safety and Health Administration (OSHA) sets guidelines for ladder safety. These regulations ensure workplace safety. Employees must follow these guidelines to prevent accidents. Understanding OSHA ladder regulations is crucial for employers and workers.

Importance Of Compliance

Compliance with OSHA ladder regulations is critical. It helps prevent workplace injuries. Non-compliance can lead to severe consequences. These include fines and legal issues. More importantly, it ensures the safety of all employees.

Accidents involving ladders are common in workplaces. Most are due to improper use or faulty ladders. By following OSHA regulations, these accidents can be minimized. This leads to a safer working environment.

Overview Of Standards

OSHA has set specific standards for ladder use. These standards cover different types of ladders. They include portable ladders, fixed ladders, and mobile ladder stands.

- Portable Ladders: Must be inspected before each use. Look for structural defects. Check rungs, steps, and side rails.

- Fixed Ladders: Require regular inspections. Ensure they are securely attached. Inspect for rust and structural damage.

- Mobile Ladder Stands: Must be stable and secure. Inspect wheels and locking mechanisms.

OSHA also mandates the use of proper techniques while using ladders. These include maintaining three points of contact. Avoiding overreaching is also crucial.

Below is a summary table of key OSHA ladder inspection requirements:

| Ladder Type | Inspection Frequency | Key Inspection Points |

|---|---|---|

| Portable Ladders | Before each use | Structural defects, rungs, steps, side rails |

| Fixed Ladders | Regularly | Secure attachment, rust, structural damage |

| Mobile Ladder Stands | Before each use | Stability, wheels, locking mechanisms |

Following these standards can save lives. It ensures a safer work environment. Inspect ladders regularly. Use them correctly. Stay compliant with OSHA regulations.

Credit: www.osha.gov

Types Of Ladders Covered

Understanding the types of ladders covered by OSHA’s inspection requirements is crucial for workplace safety. Different ladders serve different purposes and have unique guidelines. This section breaks down the main types: Portable Ladders and Fixed Ladders.

Portable Ladders

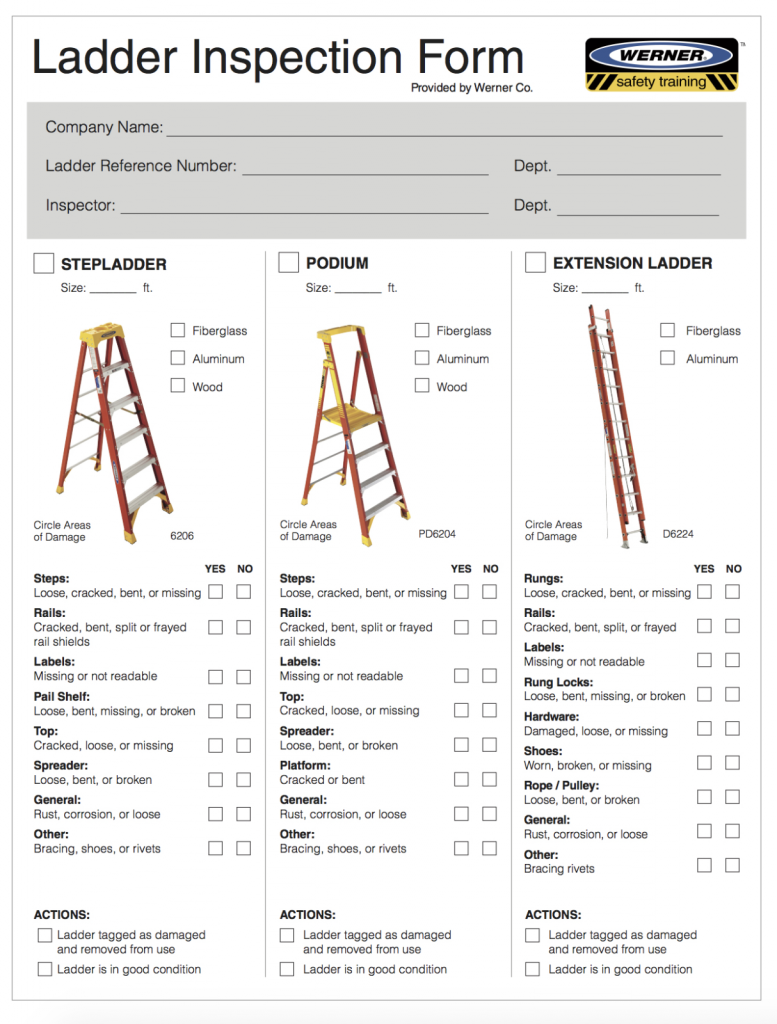

Portable ladders are movable and versatile. They are common in many workplaces. These include step ladders, extension ladders, and multi-purpose ladders. Each type has specific inspection needs. Step ladders, for example, should be checked for loose steps. Extension ladders need secure locking mechanisms. Always inspect for damage or wear. Regular checks ensure safety and functionality.

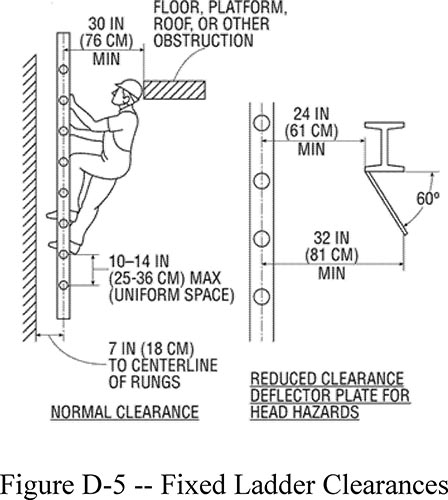

Fixed Ladders

Fixed ladders are permanently attached to structures. They are often found on industrial sites. These ladders include roof access ladders and storage tank ladders. Inspections should focus on stability. Check for corrosion and structural integrity. Ensure all fastenings are tight. Fixed ladders must meet strict OSHA guidelines. Regular inspections prevent accidents and maintain safety.

Inspection Frequency And Criteria

Ensuring the safety of ladders is crucial for workplace safety. The Occupational Safety and Health Administration (OSHA) outlines specific requirements for ladder inspections. Adhering to these guidelines helps prevent accidents and injuries. This section covers the frequency and criteria for ladder inspections.

Daily Inspections

Daily inspections are essential to identify immediate hazards. Before each use, check the ladder for damage or defects. Look for:

- Cracks or bends in the rungs and rails.

- Loose or missing parts.

- Broken or weakened components.

- Cleanliness to prevent slips.

Ensure the ladder is stable and all parts function correctly. Address any issues before use to maintain safety.

Periodic Inspections

Periodic inspections are more thorough and should be conducted regularly. These inspections involve a detailed check of all ladder components. Follow these steps:

- Examine the ladder for structural integrity.

- Check for wear and tear on moving parts.

- Ensure all safety labels are visible and legible.

- Verify that the ladder meets OSHA standards.

Documenting these inspections is important. Keep records of the inspection dates and findings. Address any issues promptly to ensure ongoing safety.

| Inspection Type | Frequency | Criteria |

|---|---|---|

| Daily Inspection | Before Each Use | Check for damage, cleanliness, and stability. |

| Periodic Inspection | Regularly (Monthly or Quarterly) | Detailed check of all components, structural integrity, and compliance. |

By following OSHA’s ladder inspection requirements, workplaces can maintain a safe environment. Regular inspections help identify and fix issues before they lead to accidents.

Credit: coloradosafetysupply.com

Common Inspection Checklist Items

Ladder inspections are critical for ensuring workplace safety. A thorough inspection includes several key items. Below are common checklist items for ensuring ladders are safe and compliant with OSHA standards.

Structural Integrity

Inspecting the structural integrity of ladders is essential. Look for any visible damage or wear. Here are some points to consider:

- Check for cracks, splits, or corrosion on the ladder.

- Ensure all rungs and steps are secure and not bent.

- Verify that no rivets or bolts are missing or loose.

- Ensure the ladder is free from any deformation.

Safety Features

Safety features are crucial for preventing accidents. Ensure the following features are in place and functional:

- Check that the ladder has non-slip feet and surfaces.

- Ensure spreader bars or locking devices are working properly.

- Verify the presence of safety labels and their readability.

- Ensure that the ladder’s weight capacity is marked and adequate for use.

Regular inspections help maintain ladder safety and compliance. A well-maintained ladder reduces the risk of workplace injuries.

Training And Recordkeeping

Ensuring safety during ladder use is critical. Training and recordkeeping are vital aspects of OSHA ladder inspection requirements. Proper training and thorough recordkeeping can prevent accidents and ensure compliance with regulations.

Employee Training

Employees must receive training on ladder safety. This includes understanding the correct use of ladders and recognizing potential hazards. Training should cover how to inspect ladders before use. It should also highlight the importance of maintaining three points of contact.

Training sessions must be regular and up-to-date. Employees should also learn how to report any ladder defects or damages. This ensures that faulty ladders are removed from service promptly.

Documentation Requirements

Maintaining accurate records is crucial. Employers must document all training sessions. Records should include the dates of training and the names of attendees. This helps in tracking who has received training and when.

Inspection records are also important. Each ladder inspection must be documented. These records should detail the condition of each ladder and note any defects found. Keeping these records organized helps in ensuring ongoing compliance with OSHA standards.

Credit: roofingmagazine.com

Frequently Asked Questions

What Are Osha Ladder Inspection Requirements?

OSHA requires regular ladder inspections. Check for damage, defects, and cleanliness. Ensure ladder stability and safety.

How Often Should Ladders Be Inspected?

Ladders should be inspected before each use. Regularly. This ensures they are safe and defect-free.

What Should Be Checked During A Ladder Inspection?

Inspect for cracks, bends, rust, and loose parts. Verify stability. Ensure all safety features are intact.

Who Is Responsible For Ladder Inspections?

Employers are responsible. They must ensure ladders are safe. Workers should also report any issues.

Conclusion

Regular ladder inspections are crucial for workplace safety. OSHA guidelines help prevent accidents. Always check for damages and wear. Train employees on proper ladder use. Maintain a detailed inspection log. This ensures compliance and safety. Regular checks save lives and reduce risks.

Remember, a safe workplace benefits everyone. Prioritize ladder inspections and stay compliant with OSHA. Safety first, always.