Choosing the right saw blade examples and uses transforms your woodworking from frustrating to flawless. This guide reveals exactly which blades to use for rip cuts, crosscuts, and specialty materials. Stop guessing and start cutting with confidence on every project.

Key Takeaways

- Blade type dictates cut quality: Match your blade to the saw and material—using a rip blade for crosscuts causes tear-out and dangerous kickback.

- Tooth count matters most: Fewer teeth (10-24) rip fast through lumber; more teeth (40-80+) deliver smooth crosscuts and plywood finishes.

- Material-specific blades prevent damage: Carbide-tipped blades cut hardwood; diamond blades handle tile; bi-metal blades slice metal without overheating.

- Maintenance extends blade life: Clean pitch buildup weekly and store blades in protective cases to avoid warping or dulling.

- Safety starts with the right blade: Never force a blade—if it binds or burns wood, it’s wrong for the cut or needs sharpening.

- Specialty blades solve tricky jobs: Dado blades create grooves; flush-cut blades trim laminates; Japanese pull-saw blades make precision joinery effortless.

Why Saw Blade Examples and Uses Make or Break Your Woodworking

Imagine this: You’ve measured twice, marked your cut line perfectly, and fired up your saw… only to watch splinters explode from the back of your board. Sound familiar? That’s the wrong blade sabotaging your project. Saw blades aren’t one-size-fits-all tools—they’re precision instruments. Choosing the right saw blade examples and uses means the difference between professional results and wasted time, materials, and frustration. In this guide, you’ll learn exactly which blades to grab for every cut, material, and saw type. No more guessing. No more tear-out. Just clean, safe, and satisfying woodworking.

Your Saw Blade Cheat Sheet: Types, Teeth, and When to Use Them

Before diving into specific saws, let’s decode blade basics. Three factors rule blade selection: tooth count, tooth geometry, and material composition.

Visual guide about Essential Saw Blade Examples and Uses for Woodworking Success

Image source: i.pinimg.com

Tooth Count: The Speed vs. Smoothness Trade-Off

Look at any blade’s edge—those jagged teeth do the real work. Here’s how count affects your cut:

- Low tooth count (10-24 teeth): Aggressive, fast cuts for ripping lumber (cutting with the grain). Leaves rough edges but gets the job done quickly. Ideal for construction framing.

- Medium tooth count (24-40 teeth): The “do-it-all” blade. Balances speed and smoothness for general carpentry. Works decently for plywood and softwoods.

- High tooth count (40-80+ teeth): Delivers glass-smooth crosscuts (cutting across the grain) and clean plywood finishes. Slower feed rate but professional results. Essential for cabinetry.

Pro Tip: For plywood, always use 60+ teeth. The thin veneer tears easily with coarse blades!

Tooth Geometry: How Teeth Shape Your Cut

Teeth aren’t just sharp—they’re engineered for specific tasks:

- Alternate Top Bevel (ATB): Teeth angled left/right. Creates clean crosscuts by shearing fibers. Best for hardwoods and plywood.

- Flat Top Grind (FTG): Straight-top teeth. Chops fibers aggressively for fast ripping. Leaves rougher edges.

- Triple Chip Grind (TCG): Alternating flat and pointed teeth. Cuts hard plastics, laminates, and non-ferrous metals without melting them.

Material Matters: What Your Blade is Made Of

A blade’s “skin” determines what it can cut:

- High-Speed Steel (HSS): Affordable, general-purpose blades. Good for softwoods but dulls fast on hardwoods.

- Carbide-Tipped: Gold standard for woodworking. Harder than steel, stays sharp 10x longer. Essential for hardwoods, plywood, and production work.

- Diamond: Cuts tile, concrete, and stone. Uses industrial diamonds bonded to the rim.

- Bi-Metal: Flexible blades for reciprocating saws. Cuts metal, plastic, and wood.

Circular Saw Blades: Your Portable Powerhouse

Circular saws are woodworking workhorses. But that default blade? It’s likely a mediocre 24-tooth rip blade. Time to upgrade!

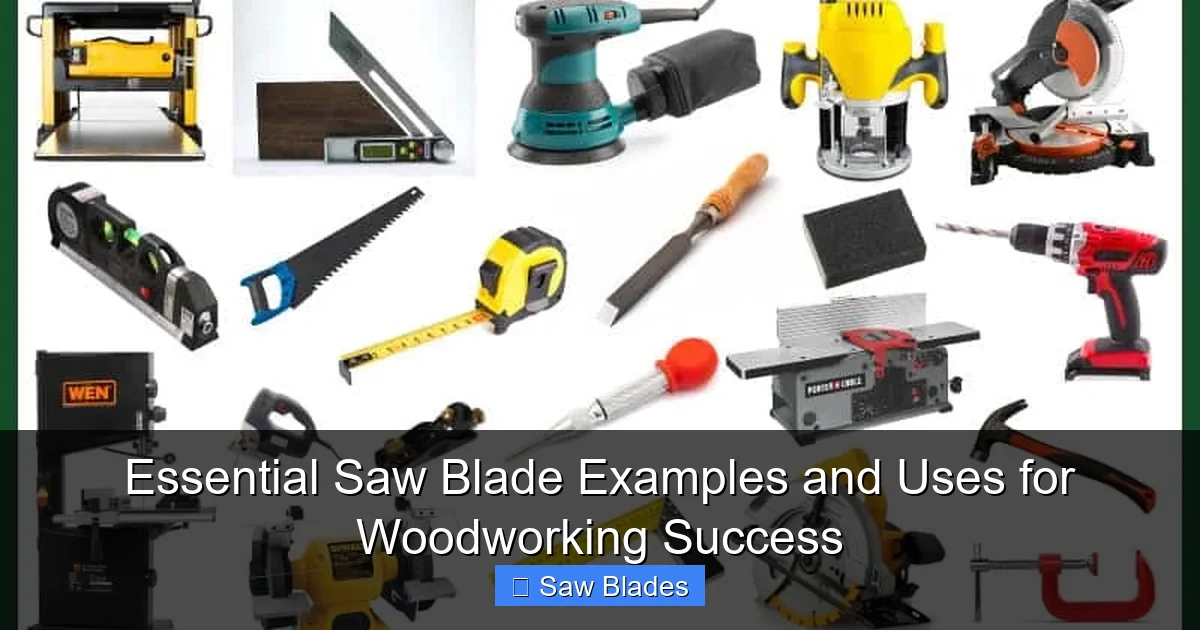

Visual guide about Essential Saw Blade Examples and Uses for Woodworking Success

Image source: res.cloudinary.com

Top Circular Saw Blade Examples and Uses

- 24-tooth FTG Rip Blade: Demolishing plywood sheets or framing walls. Fast, aggressive, and cheap. Use for: Construction lumber, rough cuts.

- 40-tooth ATB General Purpose: Your new default blade. Handles 80% of tasks—ripping, crosscutting, plywood. Use for: Decking, subflooring, DIY furniture.

- 60-tooth ATB Crosscut Blade: Cabinet-grade smoothness. Eliminates sanding on visible edges. Use for: Shelving, tabletops, trim work.

- 80-tooth Plywood Blade: Ultra-fine teeth prevent veneer tear-out. Use for: Baltic birch, furniture-grade plywood.

Pro Tip: Always cut plywood face down to minimize splintering on the visible side. Need to swap blades? Follow our step-by-step guide for circular saw blade changes to stay safe.

Table Saw Blades: Precision at High Speed

Your table saw is only as good as its blade. Ditch that old 10″ 24-tooth blade—it’s holding you back.

Visual guide about Essential Saw Blade Examples and Uses for Woodworking Success

Image source: thetoolspick.com

Must-Have Table Saw Blade Examples and Uses

- 24-tooth FTG Rip Blade: Heavy-duty ripping of 2x4s or hardwoods. Use for: Lumber mills, rough carpentry.

- 40-tooth ATB Combination Blade: The versatile MVP. Decent rip and crosscut performance. Use for: Workshop general use.

- 80-tooth ATB Crosscut Blade: Mirror-finish cuts on hardwoods. Use for: Fine furniture, musical instruments.

- Dado Blade Set (6″ or 8″): Creates grooves, dados, and rabbets in one pass. Use for: Shelving, cabinet joinery.

- Thin-Kerf Blade (1/8″ vs. 3/32″): Removes less material = less waste, smoother cuts, and reduced motor strain. Use for: Precision work on expensive woods.

Warning: Never use a dado blade in a miter saw—it’s designed for table saw arbors only. Curious how table saws work? Learn why table saws are indispensable for serious woodworking.

Miter Saw Blades: Clean Crosscuts Made Simple

Miter saws excel at crosscuts but demand high-tooth-count blades. A coarse rip blade here is a recipe for tear-out.

Best Miter Saw Blade Examples and Uses

- 60-tooth ATB Crosscut Blade: Standard for trim work. Clean cuts on softwoods. Use for: Baseboards, crown molding.

- 80-tooth ATB Crosscut Blade: Professional finish on hardwoods and plywood. Use for: Furniture frames, picture frames.

- 100-tooth ATB Fine Finish Blade: Near-sanding-free results on delicate materials. Use for: Veneered plywood, exotic hardwoods.

- Laminated Plywood Blade (TCG or Hi-ATB): Prevents chipping on melamine and laminates. Use for: Kitchen cabinets, countertops.

Pro Tip: For double-bevel miter saws, ensure your blade’s arbor hole matches the saw’s shaft size (usually 5/8″ or 1″). Confused about bevel types? See our breakdown of single vs. double-bevel miter saws.

Band Saw Blades: Curves and Resawing Masters

Band saws handle curves and thick resawing—but blade width and tooth pitch are critical.

Band Saw Blade Examples and Uses

- 1/4″ Width, 14 TPI (Teeth Per Inch): Tight curves (1/2″ radius). Use for: Scrollwork, jigsaw puzzles.

- 3/8″ Width, 6-10 TPI: General curves and resawing. Use for: Guitar bodies, bowl blanks.

- 1/2″ Width, 3-6 TPI: Heavy resawing of thick hardwoods. Use for: Lumber milling, veneer slicing.

- Skip-Tooth Blade: Wider gullet clears sawdust fast. Use for: Green wood, plastics.

Safety Note: Always lower the upper guide assembly to 1/4″ above your workpiece. Never force the blade—let it cut at its own pace.

Specialty Blades for Tricky Jobs

When standard blades fail, these specialists save the day.

Reciprocating Saw Blades

- Wood Cutting (Bi-Metal, 5-8 TPI): Demolition, pruning. Use for: Cutting tree branches, removing old cabinets.

- Metal Cutting (Carbide Grit, 10-14 TPI): Cuts pipes, rebar. Use for: HVAC work, auto repair.

- Demolition (Carbide-Tipped, 6 TPI): Cuts nails and screws embedded in wood. Use for: Renovation tear-outs.

Explore more in our reciprocating saw blade guide.

Jigsaw Blades

- Downward Curve (T-Shank): Smooth top cuts on plywood. Use for: Countertops, shelves.

- Upward Curve (U-Shank): Aggressive cuts for rough work. Use for: Drywall, insulation.

- Fine-Tooth (20+ TPI): Clean cuts on laminates. Use for: Cabinet backs, veneer.

Diamond Blades

- Continuous Rim: Smooth cuts on tile, stone. Use for: Bathroom renovations.

- Turbo Rim: Faster cuts with less chipping. Use for: Concrete, masonry.

Critical: Diamond blades must be used wet for concrete/stone to prevent overheating. Dry cutting destroys them. Learn how to spot a dull diamond blade before it ruins your project.

Troubleshooting Common Blade Problems

Even the best blade can misbehave. Here’s how to fix it:

Problem: Tear-Out on Plywood Edges

Cause: Too few teeth or dull blade.

Fix: Use 60+ tooth blade, cut face-down, apply painter’s tape over cut line.

Problem: Burning or Smoking Wood

Cause: Dull blade, wrong tooth count, or too slow feed rate.

Fix: Sharpen or replace blade, increase feed speed, switch to higher TPI blade for crosscuts.

Problem: Blade Binds or Kicks Back

Cause: Warped blade, incorrect blade for material, or forcing the cut.

Fix: Inspect blade for damage, use riving knife/splitter, let the blade cut at its own pace.

Problem: Wavy or Uneven Cuts

Cause: Loose arbor nut, dull blade, or improper saw alignment.

Fix: Tighten arbor nut, replace blade, check saw calibration.

Blade Care: Extend Life and Performance

A $50 blade can last years with proper care. Neglect it, and you’ll replace it monthly.

Cleaning Pitch and Resin

Buildup gums up teeth and causes burning. Every 2-3 uses:

- Remove blade from saw.

- Soak in warm water with dish soap for 10 minutes.

- Scrub gently with a brass brush (never steel—it scratches carbide).

- Rinse and dry thoroughly.

Storage Tips

- Hang blades vertically on a pegboard—never stack them.

- Use blade protectors or cardboard sleeves to prevent nicks.

- Store in a dry place to avoid rust.

When to Replace a Blade

Don’t wait for catastrophic failure. Replace when:

- Teeth are visibly chipped or broken.

- Cutting requires excessive force.

- Wood burns consistently despite proper technique.

- You hear grinding or screeching noises.

Conclusion: Your Path to Perfect Cuts Starts Here

Mastering saw blade examples and uses isn’t about memorizing specs—it’s about understanding how each blade interacts with wood, metal, or stone. Start with three essentials: a 40-tooth general-purpose blade, an 80-tooth crosscut blade, and a dado set for your table saw. As your projects grow more complex, add specialty blades like plywood-specific or metal-cutting options. Remember: the right blade reduces waste, prevents injuries, and turns frustrating cuts into moments of pride. Keep your blades clean, sharp, and appropriately matched to the task. Now grab that saw—your next flawless cut is waiting.

🎥 Related Video: scroll saw use

📺 Wood Art

how to use scroll saw #wood #woodart #art #artist #making #mom #scrollsaw #scroll #scrollsawproject #woodenwork scroll saw …