Discover essential saw blade safety tips to prevent serious injuries in your workshop. This guide covers blade inspection, proper technique, PPE, and maintenance for all major saw types. Follow these steps to cut confidently and keep your fingers intact.

Key Takeaways

- Inspect blades before EVERY use: Check for cracks, missing teeth, or warping. A damaged blade is a hazard waiting to happen.

- Always wear safety glasses & hearing protection: Flying debris and loud noise cause preventable eye and ear damage. Non-negotiable!

- Maintain firm control & proper stance: Keep both hands on the saw, feet shoulder-width apart, and body slightly offset from the blade path to avoid kickback.

- Use push sticks for small pieces: Never guide material with your fingers near the blade. Your hands stay safe with dedicated tools.

- Unplug saws before blade changes: Double-check power is OFF before touching the blade. One simple step prevents catastrophic accidents.

- Store blades properly: Protect teeth from damage and prevent accidental cuts by using blade guards or cases when not in use.

Hey There, DIYer! Let’s Talk Saw Blade Safety (Without the Ouch)

So, you’ve got a project that needs cutting. Maybe it’s building a bookshelf, framing a wall, or tackling that deck renovation. You grab your trusty saw, feel that surge of creative energy… and then you hesitate. What if I slip? What if the blade binds? What if I lose a finger? We get it. Saw blade safety isn’t just boring rules – it’s the difference between a satisfying project and a trip to the emergency room. OSHA reports that saw-related injuries are among the most common and severe in workshops and job sites. The scary part? Most are preventable with the right knowledge and habits.

This guide cuts through the fear (pun intended!) and gives you practical, actionable saw blade safety tips for circular saws, table saws, miter saws, and reciprocating saws. We’ll cover everything from inspecting your blade before you even plug in, to the exact stance you need to avoid kickback, to storing blades safely. By the end, you’ll know exactly how to use blades without getting hurt, turning anxiety into confident, safe cutting. Let’s get started!

Step 1: Your Blade’s First Date – The Pre-Use Inspection (Non-Negotiable!)

Think of this as your blade’s “getting to know you” session. Skipping it is like driving without checking your tires – a disaster waiting to happen. A damaged blade can shatter, kick back violently, or bind, causing severe injury.

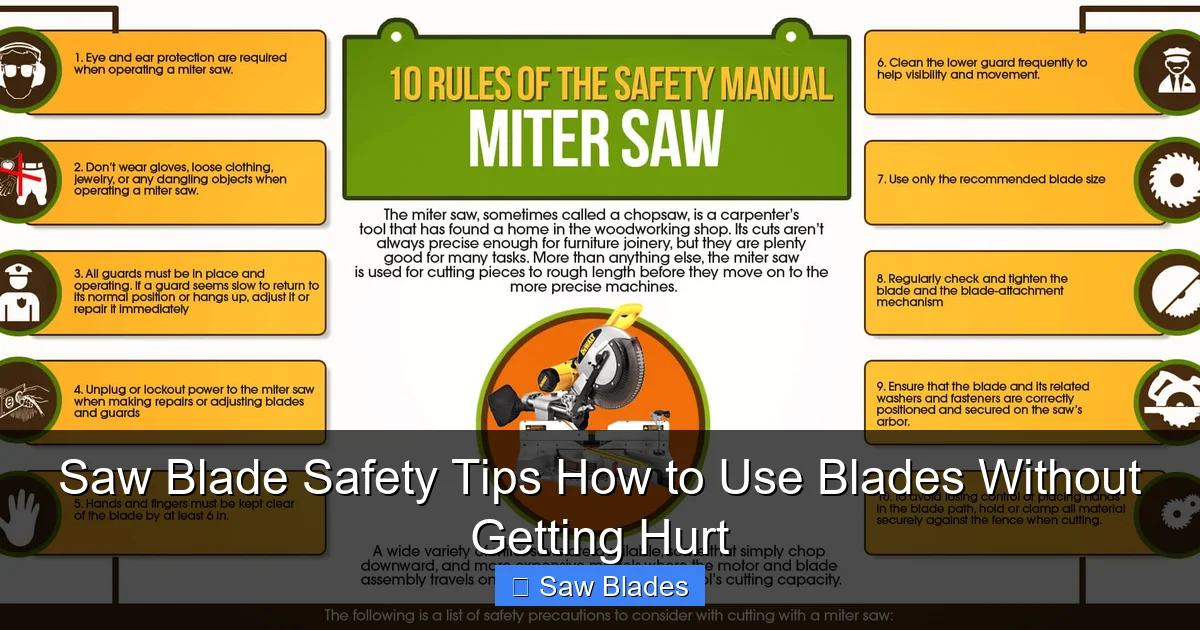

Visual guide about Saw Blade Safety Tips How to Use Blades Without Getting Hurt

Image source: storables.com

Look for the Obvious: Cracks, Chips, and Missing Teeth

Grab your blade (wearing gloves!) and hold it up to a bright light. Run your finger carefully along the edge (not the teeth!). Look for:

- Cracks: Especially near the arbor hole (the center hole) or between teeth. Even hairline cracks weaken the blade significantly. Discard immediately.

- Chipped or Missing Teeth: A single missing tooth can throw the entire blade off balance, causing vibration and potential breakage. Minor chips might be acceptable for rough work, but inspect closely.

- Warping or Bending: Place the blade flat on a known level surface (like a table saw table). Does it rock? Is there a visible curve? A warped blade won’t cut straight and is dangerous.

Pro Tip: Compare your blade to a new one of the same type if possible. Subtle damage is easier to spot side-by-side.

Check the Mounting: Is it Secure?

A loose blade is a flying blade. Before mounting:

- Ensure the arbor flange (the metal disc the blade screws onto) is clean and free of sawdust or debris.

- Verify the blade is the correct size and type for your saw (e.g., 7-1/4″ blade for a standard circular saw).

- Hand-tighten the arbor nut or bolt firmly before using the wrench. Overtightening can warp the blade; undertightening is dangerous.

- CRITICAL: Always unplug the saw or remove the battery before changing or inspecting the blade. Double-check! This is where most catastrophic accidents happen. For detailed steps on safe blade changes, see our guide on how to change a circular saw blade or changing a Ryobi table saw blade.

Step 2: Suit Up! Essential Safety Gear You Can’t Cut Corners On

Your tools are sharp, powerful, and unpredictable. Your gear is your last line of defense. Don’t be the person who says, “It’ll only take a second…”

Visual guide about Saw Blade Safety Tips How to Use Blades Without Getting Hurt

Image source: diywoodenplans.com

Eye Protection: Non-Negotiable, Always

Flying wood chips, metal shards, or even a tiny piece of broken blade can cause permanent eye damage in an instant. Safety glasses with side shields are the absolute minimum. For table saws or when cutting materials that create fine dust (like MDF), safety goggles offer better protection. Make sure they meet ANSI Z87.1 standards. No exceptions.

Hearing Protection: Save Your Ears

Saws are LOUD. Prolonged exposure causes irreversible hearing loss. Use earplugs or over-ear hearing protection rated for the noise level of your saw (usually 85+ dB). Comfort is key – if they’re uncomfortable, you won’t wear them consistently.

Hand & Body Protection: Beyond the Obvious

- Work Gloves (Use Judiciously): For handling rough material before cutting, thin mechanics gloves can help. BUT: Never wear loose-fitting gloves while operating the saw – they can get caught in the blade. For pushing small pieces, use dedicated push sticks (see Step 3).

- Long Sleeves & Pants: Protect arms and legs from flying debris and accidental contact. Avoid loose jewelry or clothing that could snag.

- Respirator/Dust Mask: Especially crucial for table saws, miter saws, and cutting composites. Inhaling fine sawdust is a serious long-term health risk. Use a NIOSH-approved N95 mask or better.

Step 3: Master the Cut – Safe Cutting Techniques That Save Fingers

Knowing how to cut is as important as the blade itself. Poor technique is a major cause of kickback and contact injuries.

Visual guide about Saw Blade Safety Tips How to Use Blades Without Getting Hurt

Image source: sawreviewed.com

Your Stance: The Foundation of Control

- Stand with feet shoulder-width apart for stability.

- Position your body slightly offset from the direct line of the blade’s path. This is VITAL for avoiding kickback – if the blade binds, the saw will try to jump back towards you. Standing slightly to the side gives you space.

- Keep your head and torso upright. Don’t hunch over the saw.

Pro Tip: Imagine the saw has a “kickback zone” directly behind it. Never stand squarely in that zone.

Hand Placement: Firm Control, Safe Distance

- Always use both hands on the saw’s handles. One hand on the main trigger handle, the other on the auxiliary handle.

- Keep your fingers away from the blade path and the trigger when not actively cutting.

- For Small Pieces: USE PUSH STICKS! This is non-negotiable for table saws and miter saws. Your fingers should NEVER be near the blade when guiding material. Push sticks (or push blocks) keep your hands safely behind the material. Learn how to make or use them – it’s a lifesaver.

Feed Rate & Blade Engagement: Smooth is Safe

- Start Slowly: Let the blade reach full speed before contacting the material. For circular saws, this means holding it just above the wood for a second.

- Steady Pressure: Apply firm, consistent pressure to feed the material through the cut. Don’t force it – let the blade do the work. Forcing causes binding and kickback.

- Avoid Freehand Cuts (Especially on Table Saws): Always use a fence, miter gauge, or guide rail to keep the cut straight and prevent the material from twisting into the blade. If you need to work at height, ensure your ladder setup follows essential ladder safety precautions.

- Watch for Kickback Triggers: Cutting warped wood, hitting nails, or having the blade bind (e.g., by cutting too close to the edge) causes kickback. If the saw suddenly jerks back, release the trigger IMMEDIATELY and regain control.

Step 4: Keep it Sharp & Safe – Blade Maintenance & Storage

A dull blade isn’t just inefficient – it’s dangerous. It requires more force, increases the risk of binding and kickback, and creates excessive heat that can warp the blade or burn the wood.

Cleaning: Remove the Gunk

Sawdust, pitch, and resin buildup on the blade reduces cutting efficiency and can cause overheating.

- Unplug the saw and remove the blade.

- Use a dedicated blade cleaning solution and a stiff-bristled brush (not wire wool – it damages teeth).

- Scrub gently between the teeth and on the blade body. Rinse thoroughly and dry completely before storage.

Pro Tip: Clean blades after every few uses, especially when cutting pine or plywood which gums up quickly.

Storage: Protect Your Investment (and Yourself)

- Always use the blade guard: Most saws come with a riving knife and blade guard assembly. Never remove or disable these safety features! They prevent accidental contact and help reduce kickback severity.

- Store blades individually: Don’t toss blades loose in a toolbox. Use the original plastic guards, blade sleeves, or a dedicated blade storage case. This protects the teeth from damage and prevents you from cutting yourself when reaching in.

- Hang or store flat: Avoid stacking heavy items on blades. Store them vertically on a rack or flat in a drawer.

Knowing how to tell if a diamond saw blade is dull is crucial for tile and masonry work – excessive chipping, slow cutting, or visible wear on the rim are key signs.

Step 5: Troubleshooting Common Saw Blade Safety Issues

Even with precautions, things can go wrong. Here’s how to handle common safety-related problems:

Problem: The Saw is Vibrating Excessively

- Likely Cause: Warped blade, loose arbor nut, damaged teeth, or incorrect blade for the material.

- Safety Fix: STOP IMMEDIATELY. Unplug the saw. Inspect the blade for warping or damage (Step 1). Check the arbor nut is tight. Ensure you’re using the right blade (e.g., fine-tooth for plywood, coarse for framing).

Problem: Kickback is Happening Frequently

- Likely Cause: Cutting warped wood, blade binding (cutting too close to edge), dull blade, missing riving knife, or improper stance.

- Safety Fix: Always use a sharp blade. Ensure the riving knife is installed and aligned correctly (it should be slightly behind the blade). Cut only straight, dry lumber. Maintain proper stance (Step 3). Use push sticks religiously for small pieces. Never stand directly behind the blade path.

Problem: Blade is Burning the Wood

- Likely Cause: Dull blade, incorrect feed rate (too slow), wrong blade type (e.g., too many teeth for rough lumber), or excessive sap/resin buildup.

- Safety Fix: A burning blade creates excessive heat, increasing fire risk and potentially warping the blade. Sharpen or replace the blade. Increase feed rate slightly (let the blade cut). Clean the blade thoroughly. Use the correct blade for the material (fewer teeth for rip cuts, more for crosscuts).

Problem: Blade Seems Loose During Cut

- Likely Cause: Arbor nut not tightened sufficiently, worn arbor flange, or incorrect blade size.

- Safety Fix: STOP. Unplug the saw. Remove the blade and inspect the arbor flange for damage. Reinstall the blade, ensuring it’s the correct size, and tighten the arbor nut firmly (but don’t overtighten). If the flange is damaged, the saw needs repair.

Conclusion: Safety is Your Most Important Tool

Let’s be real: saw blade safety tips aren’t the most exciting part of woodworking or construction. But they are the absolute foundation that lets you enjoy the creative process without fear. Remember, 90% of saw injuries are preventable with the habits we’ve covered: inspecting your blade, wearing proper PPE, using correct technique (especially push sticks!), and maintaining your tools.

Don’t let complacency creep in. That “quick cut” without safety glasses? The small piece you try to guide with your fingers? The blade you didn’t inspect because it “looked fine”? These are the moments where accidents happen. Make these safety steps automatic, like buckling your seatbelt. They take seconds but can save your sight, your hearing, or even your life.

You’ve got the knowledge now. Respect the blade, respect the power, and respect your own safety. Go build something amazing – safely. Your future self (and your fingers) will thank you.

🎥 Related Video: Table Saw Safety to Avoid Kickback #tablesaw #kickback #tablesawkickback #safety #woodworking

📺 Statedwoods Co