Confused by saw blade options? This guide simplifies everything for beginners. You’ll learn how blade teeth, materials, and designs affect your cuts across circular, band, and specialty saws. Stop guessing and start cutting with confidence using our practical selection tips.

Key Takeaways

- Blade teeth matter most: More teeth = smoother cuts (crosscutting), fewer teeth = faster rough cuts (ripping).

- Match blade to material: Wood blades have carbide tips; metal blades need fine teeth and coolant; diamond blades cut stone/concrete.

- Arbor size is non-negotiable: Your blade’s center hole MUST fit your saw’s arbor diameter (e.g., 5/8″ or 1″).

- Specialty blades save time: Use laminate blades for plywood, non-ferrous blades for aluminum, and demolition blades for tough jobs.

- Safety first: Always wear eye protection and ensure blades are sharp/dull blades cause dangerous kickback.

- Storage prevents damage: Hang blades or use protective covers to avoid bending teeth or rust.

Why Saw Blade Types Matter (Even for Beginners!)

Imagine trying to cut a delicate dovetail joint with a jigsaw blade designed for demolition. Disaster, right? That’s why understanding saw blade types is your secret weapon for safe, efficient, and professional-looking results. Whether you’re building a bookshelf, fixing a deck, or tackling a DIY metal project, the right blade transforms frustration into flawless cuts.

This guide cuts through the confusion. We’ll explain blade anatomy, decode tooth counts, and show you exactly which blade to grab for wood, metal, tile, and more. No prior experience needed—just grab your safety glasses, and let’s get started!

Blade Anatomy 101: The Parts That Make the Cut

Before diving into types, know these key parts. They determine how a blade performs:

Visual guide about Ultimate Saw Blade Types Explained for Beginners

Image source: woodsmithspirit.com

Teeth: The Cutting Powerhouses

Teeth do the actual cutting. Their shape, size, and count define the blade’s purpose:

- Tooth count (TPI): Teeth per inch. Higher TPI = smoother cuts (e.g., 80 TPI for plywood). Lower TPI = faster rough cuts (e.g., 24 TPI for dimensional lumber).

- Tooth geometry: Alternate Top Bevel (ATB) teeth slice cleanly for crosscuts. Flat Top Grind (FTG) teeth rip wood fibers apart for ripping.

Gullets: The Chip Clearers

These U-shaped spaces between teeth eject sawdust. Deeper gullets handle thick materials (like ripping lumber); shallow gullets suit fine finishes.

Plate & Kerf: The Foundation

- Plate: The blade’s flat metal body. Thicker plates resist warping.

- Kerf: The width of the cut. Standard kerf is 1/8″; thin-kerf blades (3/32″) save material but need more power.

Arbor Hole: The Critical Fit

This center hole MUST match your saw’s arbor size (usually 5/8″ or 1″). A loose fit causes dangerous wobble—never force a blade!

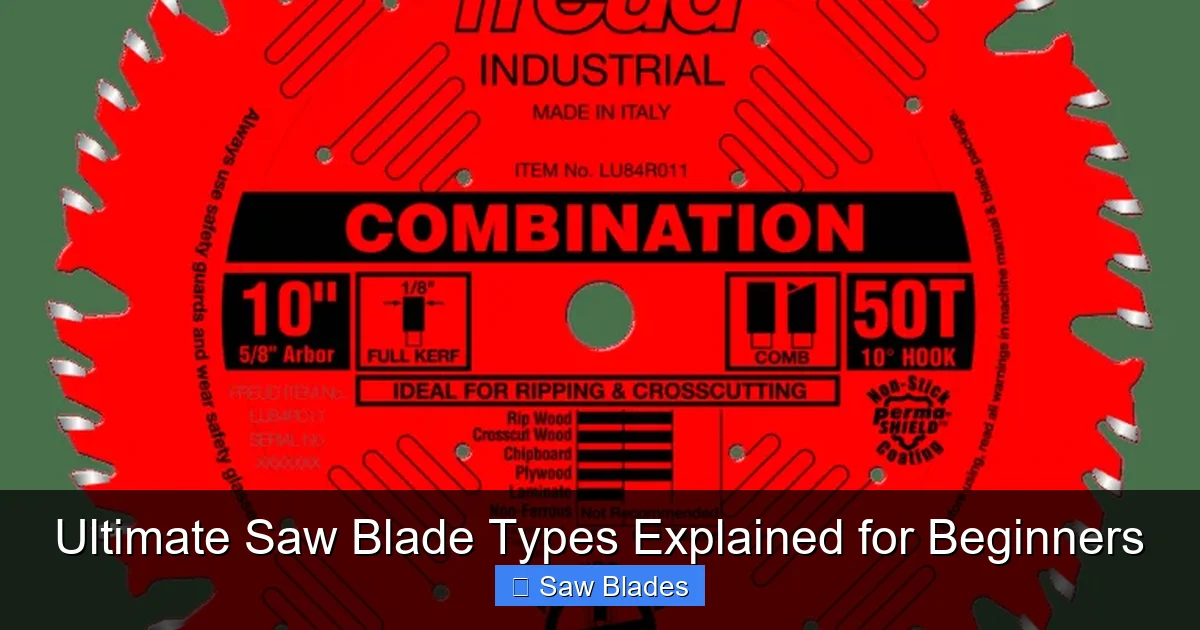

Circular Saw Blades: Your All-Around Workhorses

These spin fast for straight cuts in wood, metal, or plastic. Here’s how to pick the right one:

Visual guide about Ultimate Saw Blade Types Explained for Beginners

Image source: i.pinimg.com

Woodworking Blades

- Ripping blades (24-40 TPI): Fewer teeth, deep gullets. Perfect for cutting along the wood grain (e.g., splitting 2x4s). Use a proper blade changing technique to avoid damage.

- Crosscut blades (60-80 TPI): More teeth, shallow gullets. Slices across the grain for clean edges on plywood or trim.

- Combination blades (40-50 TPI): A jack-of-all-trades for beginners. Good for general DIY but not ideal for fine work.

- Specialty wood blades:

- Laminate blades: Extra-fine teeth (80+ TPI) prevent chipping on countertops.

- Plywood blades: Anti-friction coatings reduce splintering.

Metal-Cutting Blades

- Ferrous metal blades: Cut steel, iron. Feature fine teeth (14-36 TPI) and aluminum oxide or ceramic grit. Requires coolant to prevent overheating.

- Non-ferrous metal blades: For aluminum, copper. Have polished tops to avoid material sticking. Use at high RPMs.

Pro tip: Never use a wood blade on metal—it can shatter! Always check your saw’s RPM rating matches the blade.

Band Saw Blades: Curves and Resawing Masters

Band saws use continuous-loop blades for curves, resawing, or intricate cuts. Key factors:

Visual guide about Ultimate Saw Blade Types Explained for Beginners

Image source: thedailygardener.com

Blade Width & TPI

- Narrow blades (1/8″–1/4″): 14+ TPI. Tight curves (e.g., scrollwork).

- Medium blades (1/2″–3/4″): 6–10 TPI. General woodworking.

- Wide blades (1″+): 3–6 TPI. Resawing thick lumber.

Tooth Patterns

- Regular tooth: Standard for wood.

- Hook tooth: Aggressive cut for fast resawing.

- Skip tooth: Large gullets clear chips in green wood.

Beginner note: Start with a 1/2″ x 10 TPI hook tooth blade—it’s versatile for most projects. Learn how to sharpen band saw blades to extend its life.

Reciprocating Saw Blades: The Demolition Dynamos

These push-pull blades handle rough cuts in wood, metal, or drywall. Choose based on:

Blade Length & Material

- Wood blades (4″–12″): 5–10 TPI. Carbide tips for nails/screws. Use demolition blades for tough jobs.

- Metal blades (3″–9″): 14–24 TPI. Bi-metal or carbide for pipes/rebar.

- Demolition blades: Extra-thick with carbide grit. Cuts through nails, plaster, and wood.

Tooth Design

- Wavy set: Smooth cuts in metal.

- Alternate set: Aggressive wood cutting.

Safety first: Always cut away from your body and wear gloves—recip blades get HOT.

Diamond Blades: Cutting Stone, Concrete & Tile

These use industrial diamonds bonded to the edge for ultra-hard materials:

Blade Types

- Continuous rim: Smooth cuts in tile/stone. Best for wet cutting.

- Turbo rim: Faster dry cuts in concrete. Segmented edges prevent overheating.

- Segmented rim: Aggressive concrete/asphalt cutting. “Turbo” segments stay cool.

Critical Tips

- Wet vs. dry: Wet blades last longer but need water hookup. Dry blades are portable but overheat faster.

- Grit size: Coarse grit (for concrete), fine grit (for tile).

- Check for dullness: If it sparks excessively or cuts slowly, it’s time to replace. Learn how to tell if a diamond saw blade is dull.

Specialty Blades You’ll Actually Use

Don’t overlook these game-changers:

Miter Saw Blades

- Crosscut blades (80–100 TPI): Fine teeth for trim and molding.

- Combination blades (60 TPI): All-in-one for framing and finish work.

- Non-ferrous blades: For aluminum or brass (use with miter saws rated for metal).

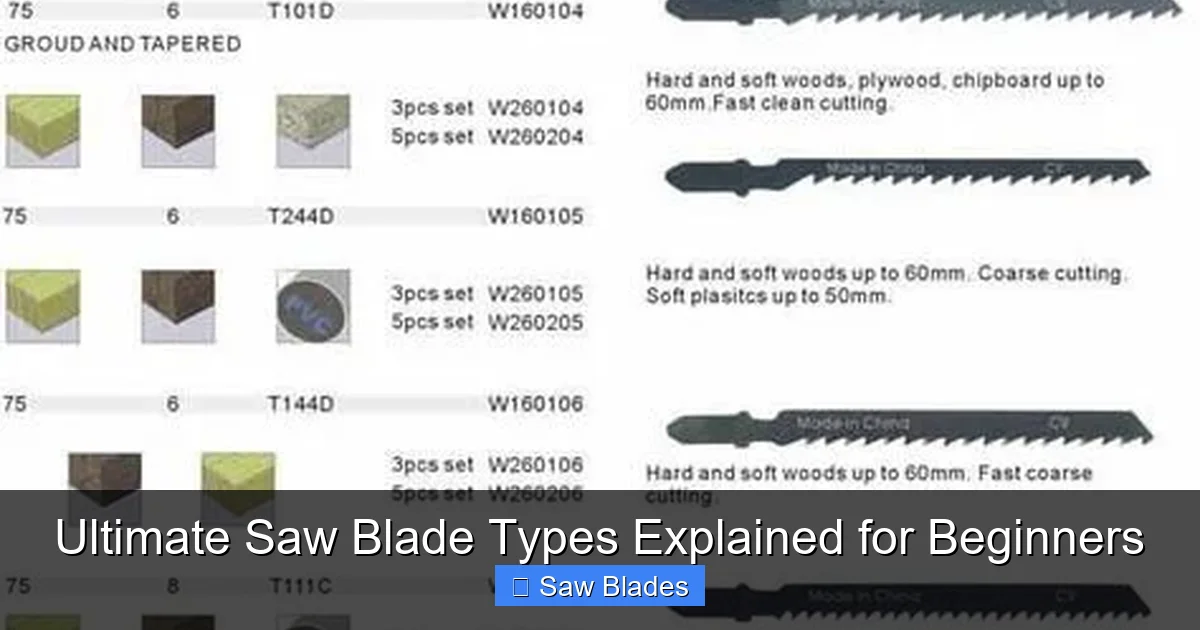

Jigsaw Blades

- Wood blades: U-shank or T-shank, 6–10 TPI.

- Metal blades: Fine teeth (14–24 TPI), bi-metal.

- Progressive pitch: Starts coarse for entry, finishes fine.

Hole Saws

- Bi-metal: For wood/metal (most common).

- Carbide-tipped: For tile/stone.

- Diamond grit: For porcelain or glass.

Pro tip: Always use pilot drills with hole saws to prevent wandering.

How to Choose the Perfect Blade: A 5-Step Checklist

Stop guessing! Follow this:

Step 1: Identify Your Material

Wood? Metal? Tile? This dictates blade type first. Never use a wood blade on metal—it’s dangerous!

Step 2: Match the Saw

Check your saw’s manual for:

- Arbor size (5/8″ or 1″)

- Max RPM (e.g., 5,800 RPM)

- Blade diameter (7 1/4″ for most circular saws)

Step 3: Determine Cut Quality Needed

- Rough cuts (framing): 24–40 TPI blade.

- Smooth finishes (cabinetry): 60–100 TPI blade.

Step 4: Consider Special Needs

- Cutting plywood? Use a plywood blade with anti-friction coating.

- Demolition work? Grab a reciprocating demolition blade.

- Wet cutting tile? Choose a continuous rim diamond blade.

Step 5: Safety Check

- Inspect for cracks or missing teeth.

- Ensure the blade is sharp (dull blades cause kickback).

- Wear safety glasses and hearing protection.

Troubleshooting Common Blade Problems

Stuck with a bad cut? Here’s why:

Problem: Burning or Smoking Wood

Cause: Dull blade, too slow feed rate, or wrong TPI.

Fix: Replace blade, push material faster, or use a lower-TPI blade for ripping.

Problem: Chipping on Plywood

Cause: Blade too dull or wrong tooth geometry.

Fix: Use a sharp crosscut blade with ATB teeth and apply masking tape over the cut line.

Problem: Blade Wobble or Vibration

Cause: Loose arbor nut, damaged blade, or incorrect arbor size.

Fix: Tighten arbor nut, replace blade, or verify arbor fit.

Problem: Metal Blade Overheating

Cause: Cutting too slowly or using a wood blade on metal.

Fix: Use a metal-cutting blade with coolant, and maintain steady pressure.

Blade Care & Storage: Extend Your Investment

Good blades last years with proper care:

Cleaning

- Rinse wood blades with water to remove pitch (dry thoroughly).

- Use a brass brush on metal blades to clear debris.

- Never soak carbide-tipped blades—it ruins the bond.

Storage

- Hang blades on a rack to avoid bending.

- Use blade guards or cardboard sleeves.

- Store in a dry place to prevent rust.

Pro tip: Label blades with their purpose (e.g., “Plywood 80T”) to avoid confusion.

Conclusion: Your Path to Perfect Cuts Starts Here

Understanding saw blade types isn’t just for pros—it’s the foundation of safe, efficient DIY. Remember: match the blade to your material, respect the arbor size, and prioritize tooth count for your cut type. Start with a versatile 40-tooth circular blade and a demolition recip blade, and you’ll conquer 80% of beginner projects.

Don’t fear mistakes—they’re part of learning. Every time you swap blades correctly, you’re building skills that turn “I hope this works” into “I nailed it!” Now grab that saw, pick your blade wisely, and create something amazing.

🎥 Related Video: Beginner Woodworker Tips on Buying the Right Saw Blades

📺 731 Woodworks

What is the best saw blade for a table saw? Best saw blade for miter saw? Best saw blade for hardwood? This is the beginner …