Discover how proper saw blade usage tips can double your blade’s lifespan and slash replacement costs. This guide covers critical maintenance routines, optimal cutting techniques, and smart storage practices for circular, table, and miter saws. Implement these steps to keep cuts clean and your wallet full.

Key Takeaways

- Match blade to material: Using the wrong blade (e.g., wood blade on metal) causes rapid dulling and dangerous kickback. Always select blades designed for your specific material.

- Control feed rate and RPM: Forcing cuts or running at incorrect speeds generates excess heat, warping blades and burning material. Let the blade cut at its natural pace.

- Clean blades after every use: Resin, pitch, and debris buildup drastically reduces cutting efficiency. A simple 5-minute cleaning routine prevents premature wear.

- Store blades properly: Hanging blades or using protective covers prevents nicks, rust, and warping that ruin expensive blades between projects.

- Recognize dullness signs early: Burning wood, excessive sawdust, or rough cuts signal it’s time for sharpening or replacement – don’t push a dull blade.

- Install blades correctly: A loose or misaligned blade vibrates, cuts inaccurately, and wears out fast. Always follow manufacturer torque specs.

Why Saw Blade Care Saves You Real Money (And Hassle)

That expensive carbide-tipped blade shouldn’t become a $50 paperweight after one project. Most DIYers and even pros waste hundreds yearly replacing blades that could last months or years with proper care. Saw blade usage tips aren’t just about sharpness – they’re about maximizing your investment through smart habits. A well-maintained blade cuts cleaner, faster, and safer. It reduces material waste from burning or chipping and prevents dangerous kickback caused by dull or damaged blades. This guide gives you actionable, step-by-step saw blade usage tips to extend life across circular saws, table saws, miter saws, and more. Stop throwing money away – learn how to make every blade count.

Step 1: Choosing the Right Blade is Half the Battle

You can’t maintain what you didn’t choose wisely. Starting with the correct blade prevents 80% of premature wear issues. Here’s how to pick smart:

Visual guide about Saw Blade Usage Tips to Extend Blade Life and Save Money

Image source: shuntool.com

Match the Blade to Your Material

Using a general-purpose wood blade on metal or masonry is a recipe for instant destruction. Always check the blade’s labeling:

- Wood: Look for “FTG” (Fiberglass Reinforced) or “ATB” (Alternate Top Bevel) teeth for clean cuts in plywood, dimensional lumber, and hardwoods. Higher tooth counts (40-80+) give smoother finishes; lower counts (24-40) cut faster in rough lumber.

- Metal: Requires specialized blades with “Cermet” or “Carbide” tips and a specific tooth geometry (often “FTG” or “Triple Chip”). Never use a wood blade on metal – it will shatter dangerously.

- Masonry/Concrete: Diamond-tipped blades are essential. Look for “continuous rim” for smooth cuts or “turbo rim” for faster, rougher cuts. Using a wood blade here destroys it instantly.

- Laminate/Plastic: Fine-toothed blades (60-100+ teeth) with a “Triple Chip” or “Hi-ATB” grind prevent chipping.

Pro Tip: When tackling mixed materials (like cutting plywood with nails), use a “demo” or “nail-cutting” blade designed for abuse. They sacrifice finish quality for durability.

Understand Tooth Count and Geometry

It’s not just about the number of teeth – the shape matters hugely:

- ATB (Alternate Top Bevel): Best for cross-cutting wood. The angled teeth slice fibers cleanly, producing smooth finishes. Ideal for plywood and finish carpentry.

- FTG (Fiberglass Reinforced / Flat Top Grind): Best for ripping wood. The flat-top teeth aggressively remove material along the grain. Common on general-purpose and rip blades.

- Triple Chip Grind (TCG): Excellent for hard plastics, laminates, and non-ferrous metals (aluminum, copper). The alternating flat and pointed teeth prevent melting and chipping.

- Low Tooth Count (24-40): Faster cuts, rougher finish, better for thick stock or dirty wood. Higher heat generation.

- High Tooth Count (60-100+): Slower cuts, smoother finish, better for thin stock or fine woodworking. Stays cooler.

Example: Cutting 3/4″ oak plywood for a bookshelf? A 60-tooth ATB blade gives a clean finish without tear-out. Cutting 2×4 studs for framing? A 24-tooth FTG blade rips through faster with less effort.

Step 2: Perfect Installation – The Foundation of Longevity

A blade installed incorrectly will wear out fast, no matter how good it is. Skipping this step negates all other care efforts.

Visual guide about Saw Blade Usage Tips to Extend Blade Life and Save Money

Image source: i.ebayimg.com

Clean the Arbor and Flange

Before mounting any blade, wipe the saw’s arbor (the shaft) and the flange (the metal washer) with a clean, dry cloth. Remove sawdust, pitch, or rust. A dirty surface prevents the blade from seating flat, causing vibration and uneven wear. This is crucial for table saws and miter saws where precision matters.

Check Blade Direction and Orientation

Most blades have an arrow showing the correct rotation direction. Installing it backward is disastrous – it won’t cut and can damage the saw. Also, ensure the blade’s kerf (cut width) matches your saw’s riving knife or splitter if applicable. For blades with a specific “top” (like some dado sets), orient it correctly.

Tighten to Manufacturer Specs (This is Critical!)

Under-tightening causes the blade to slip on the arbor, creating heat and ruining the bore. Over-tightening can warp the blade or damage the arbor threads. Always use the correct wrench and tighten to the torque specified in your saw’s manual. For most circular saws and job-site table saws, this is typically hand-tight plus a 1/4 to 1/2 turn with the wrench. Never use excessive force. If you need detailed steps for your specific saw, check our guide on how to change the blade on a Ryobi table saw or how to change a blade on a circular saw for model-specific nuances.

Step 3: Mastering the Cut – Technique Extends Life

How you cut is as important as the blade itself. Poor technique generates destructive heat and force.

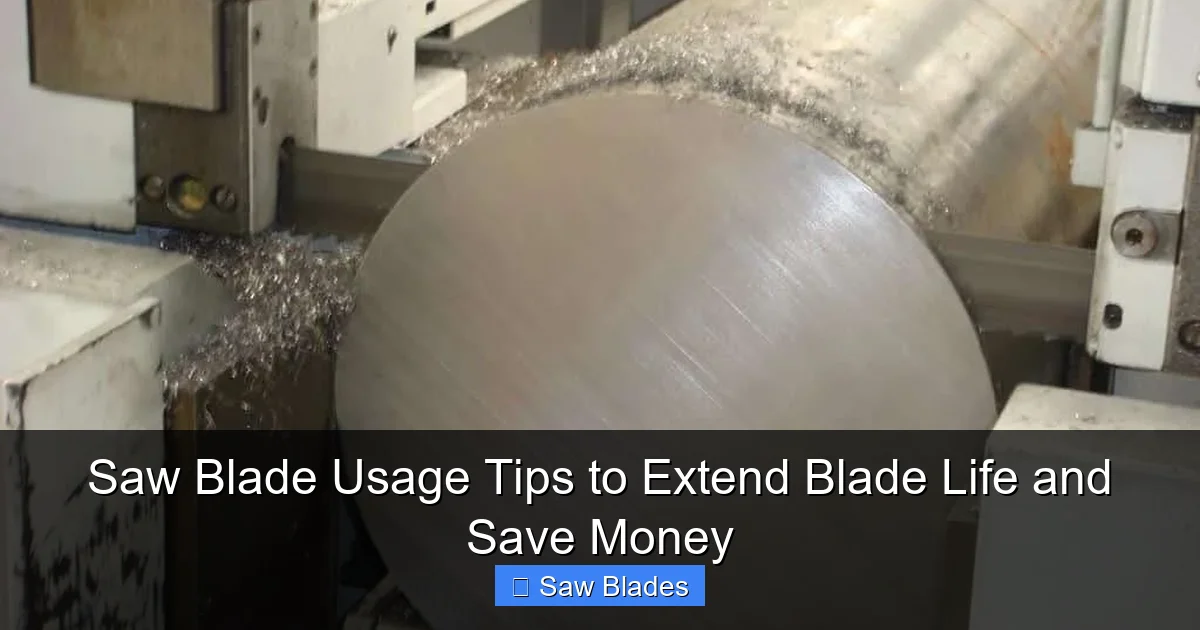

Visual guide about Saw Blade Usage Tips to Extend Blade Life and Save Money

Image source: unist.com.au

Respect the RPM (Revolutions Per Minute)

Running a blade too fast for the material or blade diameter creates excessive heat. This softens carbide tips, welds sawdust to the blade (glazing), and warps the plate. Most modern saws have fixed RPM, but for variable-speed tools (like some circular saws or angle grinders), adjust accordingly:

- Smaller Diameter Blades (4″ – 7″): Generally run at higher RPM (5,000 – 12,000+). Good for thinner materials.

- Larger Diameter Blades (8″ – 12″): Run at lower RPM (3,000 – 5,000). Essential for thicker stock to prevent overheating.

- Material Matters: Hardwoods and metals require lower RPM than softwoods or plastics. If you smell burning or see blue discoloration on the blade, you’re going too fast!

Pro Tip: When cutting dense hardwoods or metals, reduce feed rate slightly instead of cranking up RPM.

Control Your Feed Rate – Let the Blade Cut

This is the #1 mistake! Pushing too hard forces the blade, generating massive heat and strain. Pulling back or going too slow causes friction and burning. The sweet spot is a steady, moderate feed rate where the blade cuts efficiently with minimal resistance. You should hear a consistent cutting sound, not a strained whine or grinding noise. If the saw bogs down, ease up slightly – don’t force it. Forcing a cut dulls the blade exponentially faster.

Support Your Workpiece Properly

Unsupported stock can pinch the blade or cause kickback, both dangerous and damaging. Use sawhorses, outfeed tables, or clamps to keep material stable and flat. Ensure the cut line is fully supported on both sides of the blade. This prevents the blade from binding and reduces vibration, which accelerates wear.

Step 4: The Essential Cleaning Routine (5 Minutes Saves $50)

Resin, pitch, sap, and sawdust are blade killers. They insulate the teeth, reducing cutting efficiency and causing the blade to work harder (generating heat). Cleaning after every use is non-negotiable for longevity.

Gather Your Supplies

- Stiff-bristled brush (brass or nylon – never wire on carbide)

- Blade cleaning solution (commercial blade cleaner, Simple Green, or a 50/50 mix of white vinegar and water)

- Old toothbrush or small detailing brush

- Rag or paper towels

- Plastic scraper (optional, for heavy buildup)

Step-by-Step Cleaning

- Remove the Blade: Always unplug the saw or remove the battery first! Safety first.

- Initial Brush-Off: Use the stiff brush to remove loose sawdust and debris from the teeth and plate. Brush along the tooth direction.

- Apply Cleaner: Spray or soak the blade in your cleaning solution. Let it sit for 5-10 minutes to loosen pitch and resin. Don’t let it dry on.

- Scrub Gently: Use the brush (and toothbrush for gullet areas) to scrub between teeth and along the plate. Focus on areas with heavy buildup. A plastic scraper can help with stubborn gunk – be gentle to avoid nicking teeth.

- Rinse & Dry Thoroughly: Rinse with clean water if using a water-based cleaner. Wipe completely dry with a rag. Moisture causes rust.

- Inspect While Cleaning: Look for damaged teeth, cracks, or excessive wear. This is the perfect time to assess if sharpening is needed.

Pro Tip: For heavily gummed-up blades (common with pine or plywood), soaking in oven cleaner (follow safety instructions!) for 15-30 minutes can work wonders, but rinse EXTREMELY well afterward.

Step 5: Smart Storage – Protect Your Investment

How you store blades between uses prevents nicks, rust, and warping.

Never Stack Blades Loosely

Blades rubbing against each other dull teeth and warp plates. This is the fastest way to ruin expensive blades in storage.

Use Blade Protectors or Covers

Always use the plastic guard that came with the blade, or invest in reusable blade protectors. These shield the teeth from impacts and prevent contact with other blades or metal objects.

Hang or Store Vertically

Store blades on a pegboard hook or in a dedicated blade storage rack. This keeps them off damp floors, prevents warping from uneven pressure, and makes them easy to see and access. If stacking is unavoidable (e.g., in a drawer), place a piece of cardboard between each blade.

Control Humidity

Moisture causes rust. Store blades in a dry place. A small silica gel packet in your toolbox or blade storage area helps absorb moisture. Lightly coat the plate (not the teeth!) with a thin layer of machine oil or paste wax if storing long-term in a humid climate.

Troubleshooting Common Blade Problems

Spotting issues early saves blades and projects.

Problem: Burning Wood or Material

Causes: Dull blade, incorrect feed rate (too slow), wrong blade for material, excessive RPM, dirty blade (glazing).

Solution: Clean blade thoroughly. Check RPM and feed rate. Ensure correct blade type. If burning persists, blade is likely dull and needs sharpening/replacement.

Problem: Rough Cuts, Tear-Out, or Chipping

Causes: Dull blade, incorrect tooth geometry (e.g., using FTG for crosscuts), blade installed backwards, insufficient support, wrong blade for material (e.g., coarse blade on plywood).

Solution: Verify blade direction and type. Use a finer-toothed blade (ATB) for crosscuts. Ensure workpiece is fully supported. Check for dullness.

Problem: Blade Wobble or Vibration

Causes: Blade not tightened properly, warped blade, dirty arbor/flange, damaged arbor bearing.

Solution: Reinstall blade, cleaning arbor/flange and tightening correctly. Inspect blade for warping (lay flat on glass). If wobble persists after correct installation, the blade may be warped or the saw needs service.

Problem: Excessive Sawdust or “Powder” Instead of Chips

Causes: Dull blade, incorrect feed rate (too fast or slow), wrong blade for material, excessive RPM.

Solution: Clean blade. Adjust feed rate and RPM. Ensure correct blade type. Likely indicates dullness – time for sharpening.

Problem: Blue Discoloration on Blade

Causes: Severe overheating from excessive feed rate, incorrect RPM, or cutting very hard material with the wrong blade.

Solution: This indicates the blade is damaged. Carbide tips are softened, and the plate is warped. The blade needs replacement. Adjust technique immediately to prevent recurrence.

Step 6: Knowing When to Sharpen or Replace

Don’t wait until the blade is useless. Recognize the signs.

Signs It’s Time for Sharpening

- Cutting requires significantly more force than when new.

- Burning occurs even with correct technique and clean blade.

- Cut quality is noticeably rougher.

- Excessive sawdust production.

- Visible wear on the carbide tips (tips look flat or rounded).

Most quality carbide blades can be sharpened 3-10 times before the tips are too short. Professional sharpening is cost-effective for expensive blades.

Signs It’s Time for Replacement

- Cracked or chipped carbide tips (especially multiple).

- Severe warping (won’t sit flat on arbor).

- Blue discoloration on the plate.

- Teeth are visibly broken or missing.

- Blade has been sharpened to the limit (tips are very short).

- For diamond blades: Significant segment loss, core warping, or if you’re unsure, check our guide on how to tell if a diamond saw blade is dull for specific signs.

Never try to sharpen a blade with damaged tips or a warped plate – it’s unsafe and ineffective.

Conclusion: Small Habits, Big Savings

Extending your saw blade life isn’t about one magic trick – it’s the cumulative effect of smart choices every time you use your saw. By selecting the right blade, installing it correctly, mastering your cutting technique, cleaning diligently, and storing properly, you transform blade care from a chore into a routine that pays massive dividends. You’ll enjoy cleaner cuts, faster work, fewer frustrating tool failures, and most importantly, significant savings by replacing blades far less often. Implement these saw blade usage tips consistently, and that premium blade will serve you reliably for project after project. Your saw – and your wallet – will thank you. Start with just one tip today: clean your blade after your next cut. You’ll immediately notice the difference in performance.

🎥 Related Video: How to repair a bandsaw blade/and save money #woodworking #woodwork #repair #bandsaw

📺 Saif Ali Crafts

How to repair a bandsaw blade/and save money #woodworking #woodwork #repair #bandsaw #diy #wood #ad #bois #tools #tool …