Ladders are vital tools in various industries, from construction and maintenance to home improvement and even emergency rescues. However, despite their utility, ladders can pose significant risks if not properly maintained. Ladder-related accidents are a leading cause of workplace injuries, and one of the most effective ways to prevent accidents is by conducting regular ladder inspections.

Before you use a ladder, whether it’s for a construction project, cleaning, or accessing hard-to-reach places, it’s essential to check its condition to ensure it’s safe for use. An unsafe ladder can lead to falls, serious injuries, or even fatalities. In this comprehensive guide, we will walk you through the key aspects to look for when inspecting a ladder. From checking for structural integrity to ensuring the rungs and feet are in top condition, this guide will help you spot potential hazards and keep your ladder functioning at its best.

1. Understanding the Importance of Ladder Inspections

Before diving into the specifics of ladder inspection, it’s important to understand why regular checks are so critical. Ladders are exposed to various stressors, including the weight they carry, the conditions they’re stored in, and the way they’re used. Over time, these factors can cause wear and tear, which can compromise the ladder’s stability and safety.

- Prevent Accidents: Regular inspections help identify hidden issues that could lead to accidents, such as cracked rungs, worn-out feet, or unstable frames.

- Prolong Ladder Lifespan: By catching and repairing small issues early, you can extend the life of your ladder, avoiding unnecessary replacements.

- Compliance with Safety Regulations: In many industries, ladder inspections are a regulatory requirement. Ensuring that your ladder meets OSHA (Occupational Safety and Health Administration) standards is essential for compliance.

2. Types of Ladders and Their Common Uses

Before inspecting a ladder, it’s important to know what type of ladder you’re dealing with. Different ladders are built for different purposes, and each comes with unique inspection needs. Here are the most common types of ladders:

- Step Ladders: These are self-supporting ladders with a wide base, often used for indoor tasks such as painting or cleaning. They don’t require leaning against a wall but need extra care in inspecting the hinges and steps.

- Extension Ladders: These are ideal for reaching higher places. They need to be inspected for secure locking mechanisms, side rails, and feet.

- Folding Ladders: These are versatile ladders that can be folded for compact storage. Their locking mechanisms and hinges should be checked regularly.

- Platform Ladders: These ladders have a large platform at the top and are used for longer, more stable work at height. The inspection focuses on the platform stability and the condition of the platform steps.

Each type of ladder has different components, but the basic inspection checklist remains largely the same. Now let’s break down the essential elements to examine when inspecting a ladder.

3. What to Look for When Inspecting a Ladder

A thorough ladder inspection includes examining the following key parts: the ladder frame, rungs, feet, locking mechanisms, and overall stability. Let’s go through each of these in detail.

a. Frame and Structure

The frame of the ladder is its core support structure, and any damage here can compromise the entire ladder’s stability.

- Visual Inspection: Begin by examining the frame for any visible signs of damage such as cracks, dents, or bends. This is especially important for aluminum and fiberglass ladders, which can suffer from corrosion, especially in outdoor conditions.

- Rust or Corrosion: For metal ladders, look for rust spots or signs of corrosion, which weaken the frame and make the ladder unsafe to use. In fiberglass ladders, inspect for cracks or areas where the material may have become brittle due to sun exposure or aging.

- Proper Alignment: Check that the frame is properly aligned and that the legs are even. A misaligned frame could cause the ladder to lean or collapse when in use.

b. Rungs

The rungs are the most frequently used part of the ladder, so they should be in good condition to ensure safety during use.

- Cracks or Splits: Inspect each rung for cracks or splits, which can weaken the rung and make it susceptible to breaking under pressure.

- Surface Condition: Check for worn-out or slippery surfaces, particularly on wooden or metal rungs. If the rungs are slick or damaged, they can increase the risk of slips, especially if the ladder is used in wet or greasy conditions.

- Stability: Ensure the rungs are securely attached to the frame and don’t wiggle or move when pressure is applied. Loose rungs can lead to accidents.

c. Feet and Base

The feet of the ladder are essential for providing grip and stability. Without properly functioning feet, the ladder can slide or tip over easily.

- Rubber Feet: Check the rubber feet (or base pads) of the ladder for signs of wear or damage. Worn feet will reduce the ladder’s stability, making it prone to slipping on smooth or uneven surfaces.

- Even Base: Ensure that the base of the ladder is stable and in good condition. If the feet are damaged, they should be replaced immediately.

- Footwear Condition: On some ladders, especially on fiberglass or wood models, check the condition of the footwear or the bottom portion of the legs for wear and tear. Worn or chipped feet can make the ladder unstable on hard floors or uneven terrain.

d. Locking Mechanisms (For Extension Ladders)

For extension ladders and some other types of adjustable ladders, the locking mechanism is crucial to maintaining the ladder’s height and stability during use.

- Smooth Operation: Ensure the locking mechanism functions smoothly. It should click securely when the ladder is extended to the desired height.

- Check for Friction: Examine the locks for any signs of friction, sticking, or looseness. If the locks don’t engage properly, the ladder could collapse when weight is applied.

- Clear Mechanism: Make sure the locking pins, levers, or ropes (depending on the design) are not obstructed by dirt or debris.

e. Hinges and Joints (For Step and Folding Ladders)

For folding and step ladders, the hinges are a critical part of the ladder’s design and should be checked for wear or damage.

- Sturdy Hinges: Make sure the hinges are in good working order and are securely attached. Loose or worn-out hinges can cause the ladder to collapse unexpectedly.

- Smooth Folding: The ladder should open and close smoothly without any resistance or squeaks. If the folding mechanism is stiff, apply some lubricant to the hinges.

f. Weight Capacity

Each ladder has a specified weight capacity that indicates the maximum weight it can safely support, including both the user and any tools or materials being carried.

- Manufacturer’s Rating: Check the manufacturer’s label for the weight rating. This should include both the person’s weight and any additional weight (such as tools or equipment) that will be used while on the ladder.

- Overloading Risk: Never exceed the ladder’s rated weight capacity. Overloading a ladder can lead to instability and the risk of the ladder breaking.

g. Overall Stability

Once you’ve checked individual components, the next step is to test the ladder’s overall stability.

- Shaking Test: Give the ladder a light shake to check for any looseness or wobbling. A stable ladder should not wobble or sway when pressure is applied.

- Level Surface: Ensure the ladder is placed on a flat, level surface. Using the ladder on an uneven surface can lead to tipping or sliding.

h. Manufacturer’s Instructions and Recalls

Always consult the ladder’s manufacturer guidelines and any recall notices to ensure the ladder is in proper working condition and meets safety standards.

- Check for Recalls: Sometimes, ladders are subject to product recalls due to safety concerns. Regularly check the manufacturer’s website or trusted recall databases to ensure your ladder has not been recalled.

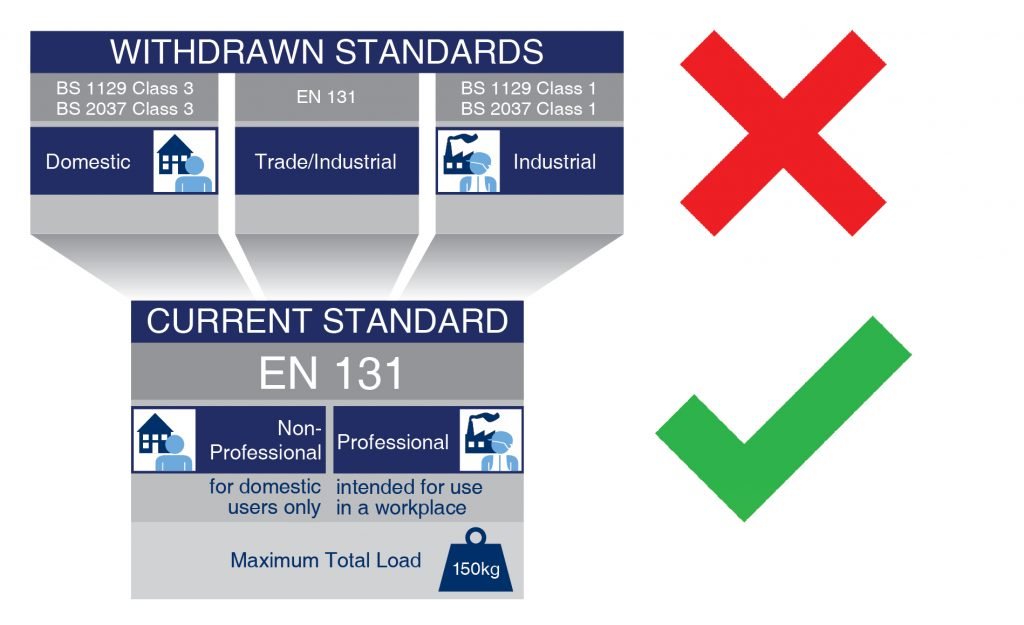

- Adherence to Standards: Ensure your ladder meets the relevant safety standards, such as OSHA or ANSI (American National Standards Institute), which govern ladder safety and quality.

4. How to Document Ladder Inspections

If you use ladders in a professional environment, it’s important to document your ladder inspections. Regular documentation helps maintain a history of your ladder’s condition and ensures that you can demonstrate compliance with safety regulations.

- Inspection Logs: Create a checklist for each ladder, noting the date of inspection, what was checked, and any issues found. Keep records of any repairs or replacements made.

- Scheduled Inspections: Perform inspections at regular intervals—ideally before each use or on a monthly basis if the ladder is in constant use.

5. Conclusion: Ensuring Safe Ladder Use

Inspecting a ladder may seem like a simple task, but it’s one of the most critical steps in maintaining a safe working environment. By following the detailed steps outlined in this guide, you can ensure that your ladder is in top condition and ready for use, reducing the risk of accidents and prolonging the life of your ladder.

Remember, a ladder is only as safe as its condition. Regular, thorough inspections will not only protect the users but also help ensure that your ladders continue to meet industry safety standards and perform reliably for years to come.

RELATED POST