OSHA requirements for ladders ensure safety at workplaces. They help prevent accidents and injuries.

Ladders are common tools in many industries, but they come with risks. OSHA, or the Occupational Safety and Health Administration, sets standards to keep workers safe. These requirements cover various aspects, from ladder design to proper usage. Understanding these rules can reduce hazards and create a safer work environment.

This blog will explore the essential OSHA ladder requirements. Knowing these guidelines helps in maintaining compliance and protecting employees. Let’s dive into the key points that every workplace should follow to ensure ladder safety.

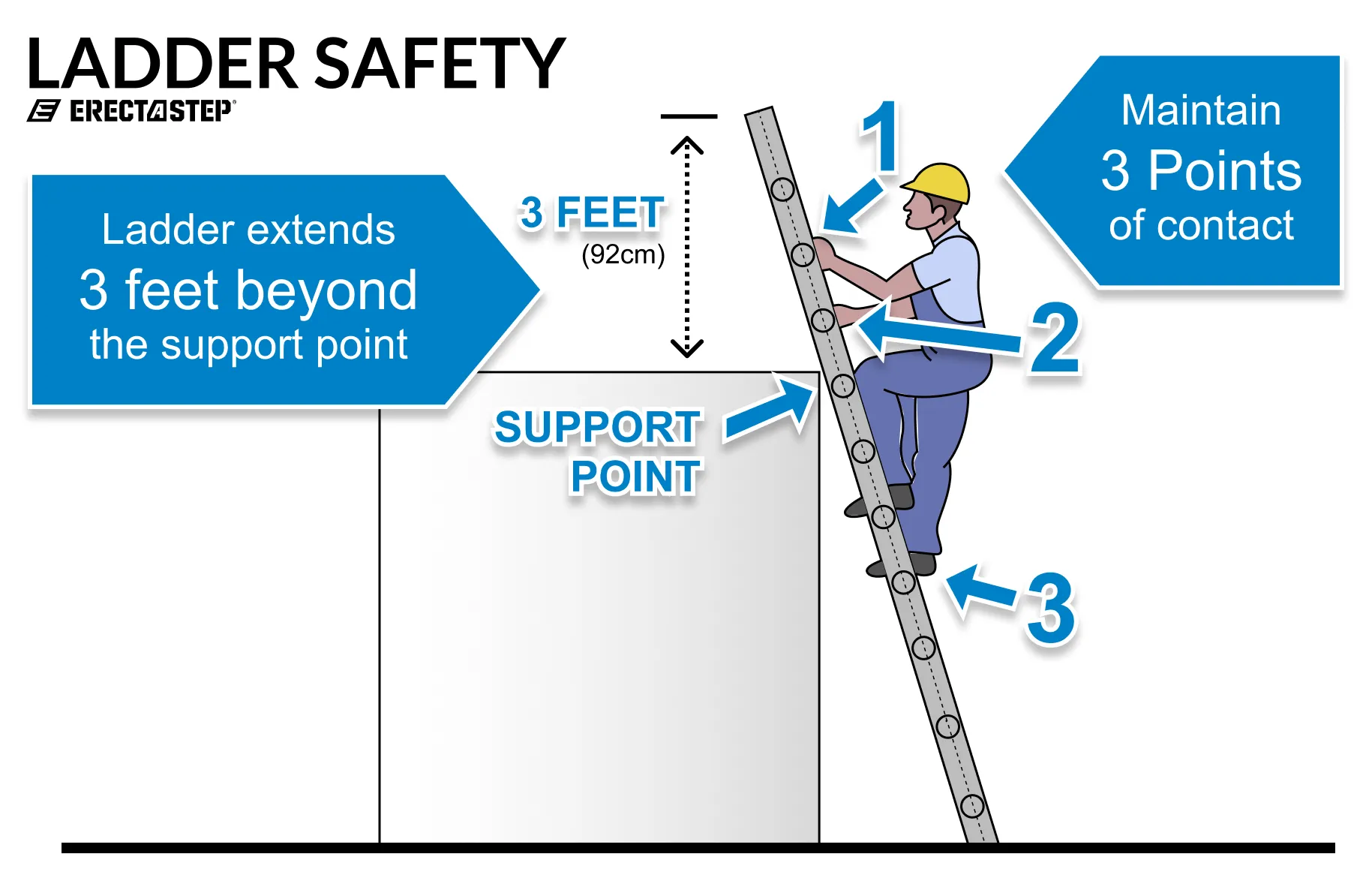

Credit: www.erectastep.com

Introduction To Osha Ladder Requirements

The Occupational Safety and Health Administration (OSHA) sets standards for ladder use in the workplace. These requirements ensure that workers use ladders safely. They help to prevent falls and injuries. Understanding these rules is vital for any employer or employee. This blog post will break down the key aspects of OSHA ladder requirements.

Importance Of Compliance

Compliance with OSHA ladder requirements is crucial. It protects workers from potential hazards. Employers must provide safe equipment. This reduces the risk of accidents. Failing to comply can result in hefty fines. It can also lead to serious injuries or fatalities. Ensuring that ladders meet OSHA standards is a simple yet effective way to safeguard your team.

Common Misconceptions

Many people have misconceptions about ladder safety. One common myth is that any ladder can be used for any task. This is not true. Ladders are designed for specific purposes. Using the wrong ladder can be dangerous. Another misconception is that older ladders are just as safe as new ones. Regular inspections are necessary. Old ladders can have hidden defects. They may not meet current OSHA standards.

| Misconception | Reality |

|---|---|

| Any ladder can be used for any task | Ladders are designed for specific purposes |

| Old ladders are just as safe as new ones | Old ladders may have hidden defects |

By understanding these key points, you can ensure a safer work environment. Always follow OSHA guidelines. Regularly inspect your ladders. Use the right ladder for the job. These simple steps can prevent accidents and save lives.

Credit: www.osha.gov

Types Of Ladders Covered

Understanding the different types of ladders is crucial for workplace safety. OSHA has specific requirements for various ladder types to ensure safety. These types include fixed ladders and portable ladders. Each type has unique features and safety standards that must be followed.

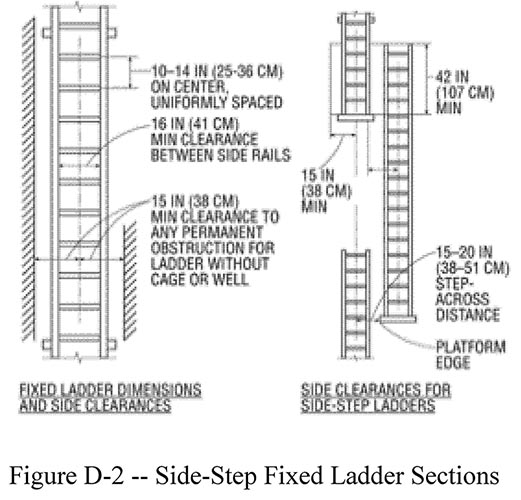

Fixed Ladders

Fixed ladders are permanently attached to a structure. They are often used in industrial settings. OSHA standards require fixed ladders to have a minimum rung width of 16 inches. The spacing between rungs should be uniform and not exceed 12 inches.

Fixed ladders over 24 feet in height must have a ladder safety system. These systems include cages, wells, or personal fall arrest systems. OSHA also requires a clear width of at least 15 inches on each side of the ladder centerline.

| Requirement | Specification |

|---|---|

| Minimum Rung Width | 16 inches |

| Rung Spacing | 12 inches |

| Height for Safety Systems | Over 24 feet |

| Clear Width | 15 inches |

Portable Ladders

Portable ladders are not fixed and can be moved as needed. They include step ladders and extension ladders. OSHA requires portable ladders to support at least four times the maximum intended load. Step ladders must have spreaders to lock the ladder open. This prevents accidental collapse.

Extension ladders should have a minimum overlap of 3 feet for sections up to 36 feet. For sections over 36 feet, the overlap must be 4 feet. Always inspect portable ladders before use to ensure they are in good condition.

- Step ladders must have spreaders.

- Extension ladders require a 3-foot overlap for sections up to 36 feet.

- For sections over 36 feet, a 4-foot overlap is necessary.

Following these OSHA requirements helps prevent accidents. Safety is a priority in any work setting. Knowing the standards for fixed and portable ladders is essential.

General Ladder Safety Rules

Ladders are essential tools in many workplaces. They help workers reach heights safely. But improper use can lead to accidents. OSHA has specific requirements for ladder safety. Knowing these rules can prevent injuries and ensure safe operations.

Inspection Protocols

Before using a ladder, always inspect it. Look for cracks or missing parts. Ensure all rungs and steps are intact. Check the feet of the ladder for wear. Make sure it is clean and free of oil or grease.

- Visual Check: Look for visible damage.

- Structural Integrity: Test for stability.

- Moving Parts: Ensure locks and hinges work.

If you find any defects, do not use the ladder. Report it to your supervisor immediately.

Safe Usage Guidelines

Using a ladder safely requires following specific guidelines. Always place the ladder on a stable surface. Ensure it is fully extended and locked in place before climbing.

- Three Points of Contact: Keep two hands and one foot, or two feet and one hand, on the ladder at all times.

- Proper Angle: Position the ladder at a 75-degree angle.

- Weight Limit: Do not exceed the ladder’s weight capacity.

- Top Rung: Never stand on the top rung or step.

Do not carry heavy or bulky items while climbing. Use a tool belt or hoist materials instead. Always face the ladder when ascending or descending.

Following these safe usage guidelines ensures you stay secure while working on ladders. Proper ladder safety can prevent accidents and keep everyone safe.

Specific Requirements For Fixed Ladders

Fixed ladders are essential for many workplaces. The Occupational Safety and Health Administration (OSHA) has specific rules for them. These rules keep workers safe. Let’s explore these requirements.

Design Standards

OSHA has clear design standards for fixed ladders. Fixed ladders must be able to support the maximum intended load. The rungs must be uniformly spaced, usually 12 inches apart. Each rung must be at least 16 inches wide.

| Design Element | Requirement |

|---|---|

| Load Capacity | Support maximum intended load |

| Rung Spacing | 12 inches apart |

| Rung Width | At least 16 inches |

Side rails must extend 42 inches above the top of the ladder. This provides a secure handhold for workers. If the ladder is over 24 feet, safety devices like cages or wells are required.

Maintenance Requirements

Regular maintenance is crucial. Fixed ladders must be inspected before each use. Look for damage or wear. Rungs and rails must be in good condition. Loose or damaged parts need immediate repair.

- Inspect before each use

- Check for damage or wear

- Repair loose or damaged parts

Cleaning the ladder is also important. Dirt and grease can cause slips. Keep the ladder clean and dry. This ensures a safe climb every time.

Specific Requirements For Portable Ladders

Understanding OSHA requirements for portable ladders ensures workplace safety. OSHA sets strict guidelines to prevent accidents. This section covers key areas like material specifications and load capacity limits for portable ladders.

Material Specifications

OSHA specifies materials for portable ladders to ensure durability and safety. Common materials include wood, aluminum, and fiberglass. Each material has unique properties and usage scenarios.

- Wood: Must be free from defects and decay.

- Aluminum: Lightweight and resistant to corrosion.

- Fiberglass: Non-conductive, ideal for electrical work.

All materials must meet OSHA standards. Proper maintenance is crucial. Inspect ladders regularly for damage.

Load Capacity Limits

OSHA mandates load capacity limits for portable ladders. This ensures the ladder can support its intended weight. Ladders are categorized based on their duty rating.

| Duty Rating | Load Capacity |

|---|---|

| Type I | 250 lbs |

| Type IA | 300 lbs |

| Type IAA | 375 lbs |

Select the right ladder type based on the job requirements. Overloading a ladder is dangerous. Always adhere to the specified load limits.

By following OSHA’s specific requirements for portable ladders, you can ensure a safer working environment. Regular inspections and proper usage are key to compliance.

Credit: www.erectastep.com

Training And Certification

Ensuring ladder safety is crucial in the workplace. OSHA mandates specific training and certification requirements. This guarantees that employees are well-prepared to use ladders safely. Proper training helps prevent accidents and ensures compliance with OSHA standards.

Employee Training Programs

Employee training programs are essential for ladder safety. These programs should cover the following key points:

- Proper ladder selection

- Inspection procedures

- Safe usage techniques

- Fall prevention strategies

Training should be interactive and hands-on. Employees learn best by practicing ladder safety in real-world scenarios. Training sessions should be conducted regularly. This ensures that all employees stay up-to-date with the latest safety practices.

Record-keeping Practices

Maintaining accurate records is a vital part of OSHA compliance. Employers should document all training sessions. This includes:

- Dates of training

- Names of attendees

- Topics covered

- Trainer information

Accurate record-keeping helps in tracking employee progress. It also provides proof of compliance during OSHA inspections. Employers should store these records in a secure and easily accessible location. Digital record-keeping can be beneficial for easy retrieval and backup.

Frequently Asked Questions

What Are The Basic Osha Ladder Requirements?

OSHA requires ladders to be stable, non-slip, and regularly inspected. They should be used correctly to avoid falls.

How Often Should Ladders Be Inspected?

Ladders should be inspected before each use. Regular checks ensure they are safe and functional.

Can Ladders Be Painted According To Osha?

No, OSHA prohibits painting ladders. Paint can hide defects and damage, making them unsafe.

What Materials Are Approved For Ladders By Osha?

OSHA approves ladders made of wood, metal, and fiberglass. These materials are strong and durable.

Are There Weight Limits For Ladders Under Osha?

Yes, OSHA sets weight limits. Ladders must support the user’s weight and any tools or materials.

Conclusion

Understanding OSHA requirements for ladders is crucial for workplace safety. Following these guidelines reduces risks and accidents. Regular inspections and proper training ensure everyone’s safety. Always use the right ladder for the task. Maintain three points of contact while climbing.

Secure the ladder on stable ground. Remember, safety first. Simple steps can prevent serious injuries. Stay informed and stay safe.