Inspecting ladders is crucial for safety. Identifying defects prevents accidents and ensures reliability.

Ladders are essential tools in many tasks, from home repairs to construction projects. But they can pose risks if not properly maintained. Regular inspections help you spot potential issues early. In this blog post, we will explore three common defects to look for when inspecting ladders.

Understanding these defects can help you maintain a safe working environment. Whether you’re a professional or a DIY enthusiast, this guide will provide valuable insights to keep your ladders safe and functional. Let’s dive into these critical aspects of ladder safety and ensure every climb is secure.

Introduction To Ladder Safety

Ladder safety is crucial. Many accidents occur due to faulty ladders. Regular inspections can prevent these mishaps. Understanding what to check is essential. This blog will guide you through the process.

Importance Of Regular Inspections

Regular ladder inspections ensure your safety. They help identify potential issues before they cause accidents. Inspections should be routine. This maintains the ladder’s integrity and extends its lifespan.

Here are some reasons why regular inspections are important:

- Prevents accidents and injuries

- Increases ladder lifespan

- Ensures compliance with safety regulations

Common Ladder Use Cases

Ladders are used in many scenarios. Each use case requires a sturdy and safe ladder. Here are some common ladder use cases:

- Home maintenance and repairs

- Construction work

- Painting and decorating

- Warehouse and storage access

In each case, a proper inspection can prevent accidents. Safety should always be the top priority.

By understanding ladder safety and conducting regular inspections, you can avoid potential dangers. This blog will help you identify the three key defects to look for.

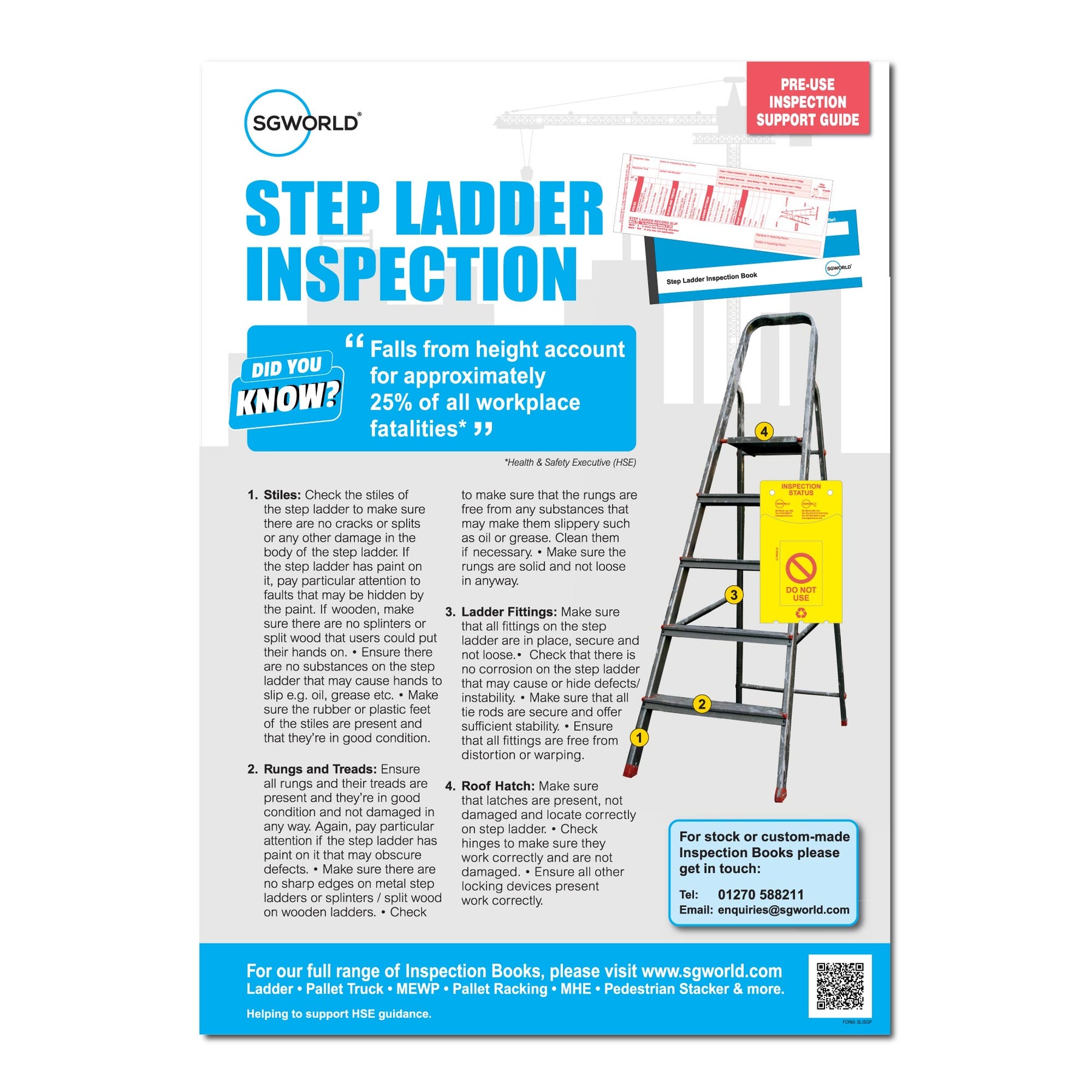

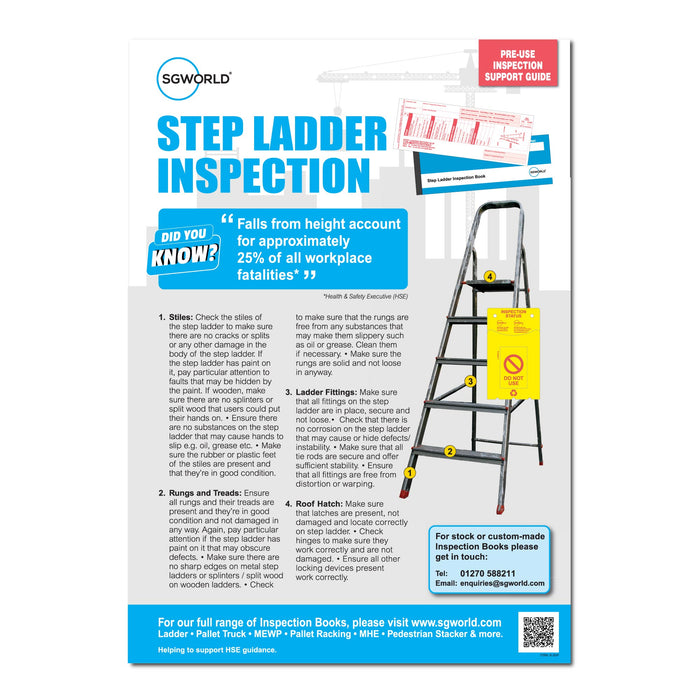

Credit: www.sgworld.com

Structural Integrity

Ensuring the structural integrity of a ladder is vital for safety. A ladder with compromised integrity can lead to accidents and injuries. Regular inspections help identify potential hazards early on. Here are three key defects to look for when assessing a ladder’s structural integrity.

Checking For Cracks And Bends

Cracks and bends weaken a ladder and make it unsafe. Examine the ladder’s rungs, rails, and other components. Look for any visible cracks in the material. Use your hands to feel for bends and distortions. Even small cracks can grow over time, leading to ladder failure.

Check both sides of the ladder. Pay attention to the joints and connections. Bent rungs or rails can indicate excessive stress or damage. Replace the ladder if you find any significant cracks or bends.

Inspecting Welds And Bolts

Welds and bolts hold the ladder together. Inspect these areas closely. Look for any signs of rust or corrosion. Rust weakens the metal, making the ladder less stable. Tighten any loose bolts and replace any that are missing.

Check the welds for cracks or gaps. Poorly welded joints can fail under pressure. Ensure the welds are smooth and intact. If you find any issues with the welds or bolts, consider repairing or replacing the ladder.

| Defect | Signs to Look For | Action |

|---|---|---|

| Cracks | Visible lines or fractures in material | Replace ladder |

| Bends | Distorted or uneven rungs/rails | Replace ladder |

| Rust/Corrosion | Discoloration or flaking metal | Clean and tighten bolts |

| Loose/Missing Bolts | Loose connections | Tighten or replace bolts |

| Poor Welds | Cracks or gaps in welds | Repair or replace ladder |

Stability And Balance

When inspecting ladders, checking for stability and balance is crucial. A ladder that wobbles or tilts can lead to accidents. Ensuring that your ladder maintains firm contact with the ground and does not sway is vital for safety.

Assessing Foot Pads And Shoes

The foot pads and shoes of a ladder are essential for stability. They provide the necessary grip and prevent the ladder from slipping. Inspect the foot pads for any signs of wear and tear. Ensure that they are not cracked or damaged. If they are worn out, replace them immediately.

Check the shoes of the ladder as well. These are the rubber or plastic coverings at the bottom of the ladder’s legs. They should be intact and securely attached. Any damage here can compromise the ladder’s stability.

Evaluating Extension Locks

Extension locks are another critical component. They keep the ladder sections securely in place. Inspect the locks for any signs of rust or corrosion. They should move smoothly and lock firmly without any loose parts.

Ensure that the locks engage properly when the ladder is extended. Test them by extending and retracting the ladder a few times. If the locks do not function correctly, the ladder may collapse unexpectedly, leading to serious injuries.

| Component | What to Check | Action Needed |

|---|---|---|

| Foot Pads | Check for cracks or damage | Replace if worn out |

| Shoes | Ensure they are intact and secure | Replace if damaged |

| Extension Locks | Look for rust and smooth operation | Repair or replace if faulty |

Credit: esafety.com

Rungs And Steps

The rungs and steps of a ladder are crucial parts. Ensuring they are in good condition is vital for safety. Let’s explore three key defects to check during an inspection.

Ensuring No Slippage

Rungs and steps must provide a firm grip. Check for any signs of slippage. Use your hand to feel if the surface is smooth or slick. A slippery rung can lead to accidents. Look for worn-down textures or missing treads. These can be dangerous.

Ensure the rungs have anti-slip features. This might include rubber grips or textured surfaces. If the ladder is wet, dry it off. Water can make rungs slippery too. Always prioritize a secure footing.

Inspecting For Wear And Tear

Wear and tear are common over time. Inspect the rungs and steps for any signs of damage. Look for cracks, dents, or bends. These can weaken the ladder’s structure.

Pay attention to rust and corrosion. Metal ladders are prone to rusting. Wooden ladders can splinter. Both can affect stability. Use a flashlight to spot hidden damages. Regular checks can prevent accidents.

| Defect | Check For | Action Needed |

|---|---|---|

| Slippage | Smooth surface, missing treads | Add anti-slip features, dry off water |

| Wear and Tear | Cracks, dents, bends, rust, splinters | Repair or replace damaged parts |

Safety Features

Inspecting ladders is crucial for ensuring safety. One must pay attention to various safety features during an inspection. This section will guide you through the critical safety features to check. Ensuring these features are intact can prevent accidents and injuries.

Reviewing Safety Labels

Safety labels provide essential information. They often include the ladder’s weight capacity and proper usage instructions. Ensure these labels are present and readable. Missing or damaged labels can lead to misuse and accidents. Check for wear and tear on the labels. This can indicate the ladder’s overall condition.

Testing Locking Mechanisms

Locking mechanisms are vital for ladder stability. Test these mechanisms to ensure they function correctly. Engage and disengage the locks several times. They should move smoothly and lock securely. A faulty locking mechanism can cause the ladder to collapse. This can result in severe injuries. Regular testing can prevent these hazards.

Credit: www.sgworld.com

Maintenance Tips

Keeping your ladder in top shape is crucial for safety. Regular maintenance ensures longevity and reliability. Here are some practical tips to help you keep your ladder in excellent condition.

Regular Cleaning Practices

Clean your ladder after each use. Dirt and debris can cause slips and falls. Use mild soap and water for metal ladders. Wooden ladders should be wiped down with a damp cloth. Avoid soaking wooden ladders to prevent warping. Inspect for any damages while cleaning. Look for cracks, loose rungs, and worn-out steps.

Proper Storage Techniques

Store your ladder in a dry, cool place. Avoid exposure to extreme temperatures. Hang ladders horizontally on sturdy hooks. This prevents bending and warping. Ensure the storage area is free from moisture. Moisture can cause rust on metal ladders and rot on wooden ladders. Secure the ladder to prevent falls and injuries.

Frequently Asked Questions

What Should I Check For Ladder Stability?

Check if the ladder has firm, non-slip feet. Ensure it’s not wobbly or unstable.

How Do I Inspect Ladder Steps?

Look for cracks, bends, or missing rungs. Ensure each step is secure and undamaged.

Why Is Checking Ladder Hinges Important?

Hinges should be intact and rust-free. Damaged hinges can lead to accidents and injuries.

Are Ladder Labels Important?

Yes, labels provide safety instructions and weight limits. Ensure they are readable and in good condition.

How Often Should Ladders Be Inspected?

Inspect ladders before each use. Regular checks ensure safety and prevent accidents.

Conclusion

Inspecting ladders is vital for safety. Focus on identifying three key defects. Check for cracks, loose rungs, and rust. These issues compromise ladder stability. Regular inspections prevent accidents. Safety must always come first. Always inspect before using a ladder. Spot defects early to avoid injuries.

Ensure ladders are in good condition. This keeps everyone safe. Happy climbing!