A coping saw is a type of hand saw with a thin, narrow blade. It’s used for intricate cutting and shaping wood, plastic, and metal.

A coping saw is essential for detailed woodworking projects. Its thin, narrow blade allows for tight curves and complex shapes, making it ideal for tasks like cutting moldings, trim, and creating intricate patterns.

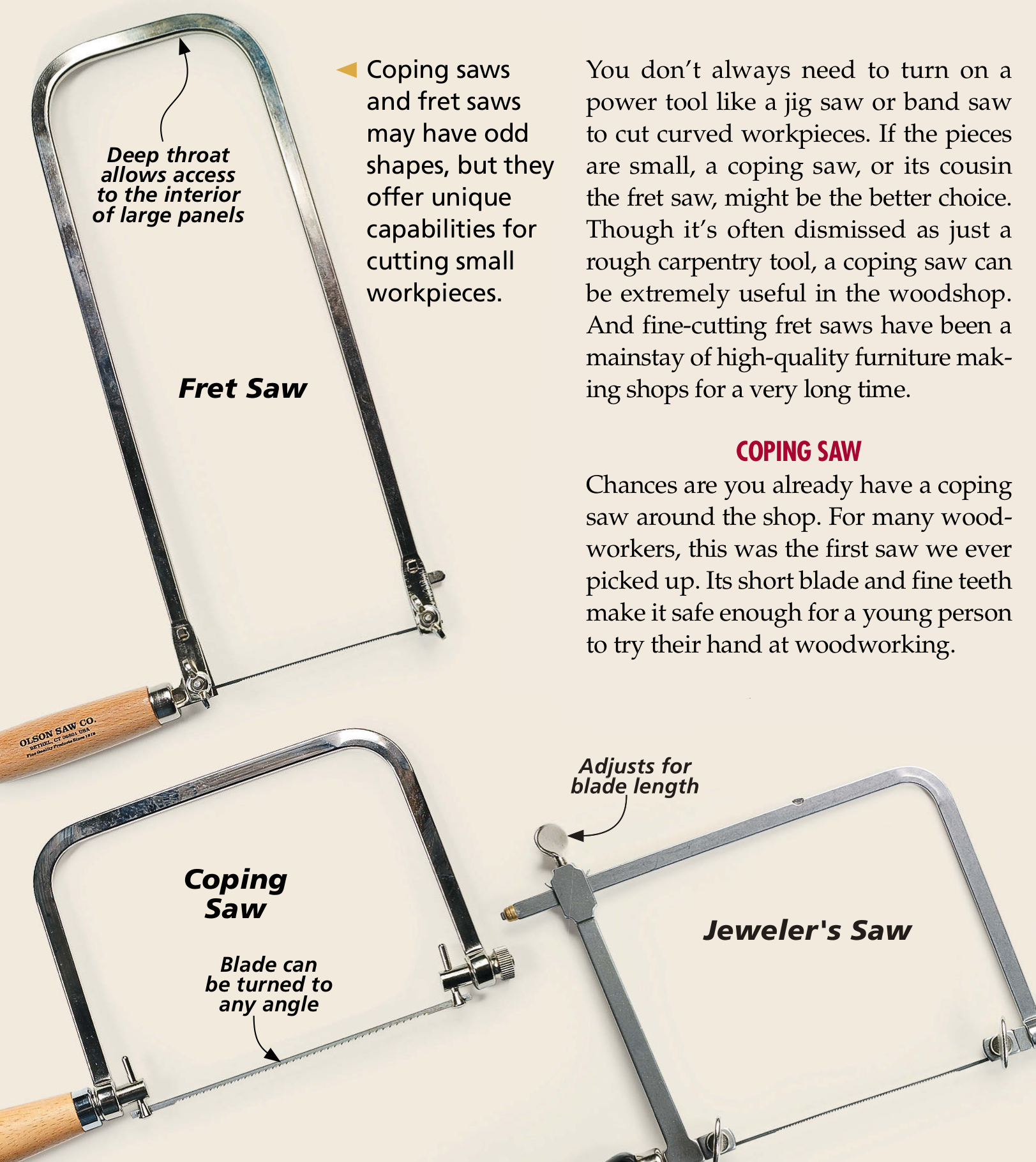

The saw’s design includes a U-shaped frame that holds the blade in tension, ensuring precise cuts.

Woodworkers, carpenters, and DIY enthusiasts often use it for tasks requiring high accuracy. It’s a versatile tool that can handle various materials, making it a valuable addition to any workshop.

Its ease of use and ability to make precise cuts make the coping saw indispensable for fine craftsmanship.

Credit: www.woodsmith.com

Introduction To Coping Saws

A coping saw is a handheld tool used in woodworking. It is designed for intricate cuts. The saw has a thin, narrow blade. This blade is ideal for cutting curves and shapes. The tool is lightweight and easy to handle.

Brief History

The coping saw has a long history. It dates back to the 16th century. Craftsmen used it for fine woodworking. The saw evolved over time. Today, it is a staple in many workshops. Its design remains largely unchanged. This speaks to its effectiveness and utility.

Key Features

| Feature | Description |

|---|---|

| Blade | Thin, narrow, and replaceable |

| Frame | U-shaped, allowing for deep cuts |

| Handle | Ergonomic for comfortable grip |

The coping saw blade is usually around 6 inches long. It can be easily replaced. The U-shaped frame holds the blade in place. This frame allows for deep cuts without obstruction. The handle is ergonomic. It ensures a comfortable grip during use.

- Blade Tension: Adjustable for precise cutting

- Versatility: Suitable for wood, plastic, and metal

- Portability: Lightweight and easy to carry

The blade tension can be adjusted. This ensures precise cutting. The saw is versatile. It can cut wood, plastic, and metal. The lightweight design makes it portable. It is easy to carry and store.

Design And Structure

The design and structure of a coping saw make it unique. It has three main parts: the frame, blade, and handle. Each part is important for different tasks.

Frame

The frame of a coping saw is U-shaped. It holds the blade in place. The frame is often made of metal. This makes it strong and durable. The frame can be adjusted to fit different blade lengths. This helps in cutting various shapes and materials.

Blade

The blade is thin and narrow. It has small, sharp teeth. The blade is replaceable, which adds flexibility. Blades come in different sizes and tooth patterns. This allows for precise cuts. The blade can be rotated. This helps in making curved cuts easily.

Handle

The handle is usually made of wood or plastic. It is designed for a comfortable grip. The handle connects to the frame. It helps control the saw during cutting. A good handle reduces hand fatigue. This makes it easier to use for longer periods.

How A Coping Saw Works

A coping saw is a versatile tool for cutting intricate shapes. It is used in woodworking, metalworking, and crafting. This tool has a thin, narrow blade attached to a U-shaped frame. Let’s explore how this amazing tool works.

Cutting Action

The cutting action of a coping saw is unique. The blade is thin and narrow, which allows for tight curves and detailed cuts. You pull or push the saw to cut through the material. This action makes it perfect for cutting out patterns and shapes.

The blade’s teeth point towards the handle. This design ensures smooth cuts on the pull stroke. The saw can cut wood, plastic, and even some metals. It excels in making precise cuts and intricate designs.

Blade Tension

Blade tension is crucial for a coping saw’s performance. The blade must be tight for clean and accurate cuts. Most coping saws have a mechanism to adjust the blade tension. This mechanism is usually a knob or lever on the frame.

Adjust the tension to ensure the blade does not bend or break. A properly tensioned blade cuts smoothly and accurately. If the blade is too loose, it will wobble and make uneven cuts. If it is too tight, it may break.

| Feature | Description |

|---|---|

| Blade | Thin and narrow, ideal for detailed cuts |

| Frame | U-shaped to hold the blade tightly |

| Teeth Direction | Point towards the handle for smooth cuts |

| Tension Mechanism | Knob or lever for adjusting blade tension |

In summary, the coping saw is a handy tool. Understanding its cutting action and blade tension helps you use it effectively. This tool is essential for intricate and detailed cutting tasks.

Common Uses

A coping saw is a versatile tool. It is used in many different tasks. This saw can cut intricate shapes and curves. Let’s explore its common uses in various fields.

Woodworking

In woodworking, a coping saw is essential. It can cut curves and detailed shapes in wood. This saw is perfect for making dovetail joints. Many woodworkers use it for trimming and molding. It is also great for cutting out designs from wood panels.

Metalworking

A coping saw isn’t just for wood. It can also cut soft metals. Metalworkers use it for crafting intricate designs. It is useful for cutting thin metal sheets. The fine blade allows precise cuts. It is perfect for detailed metal projects.

Crafting

Crafting enthusiasts love the coping saw. It is perfect for cutting various materials. People use it for hobbies like model making. It can cut plastic, foam, and other soft materials. Its versatility makes it a favorite among crafters.

| Field | Common Uses |

|---|---|

| Woodworking | Cutting curves, dovetail joints, trimming, molding |

| Metalworking | Crafting designs, cutting thin metal sheets |

| Crafting | Model making, cutting plastic, foam |

The coping saw is a must-have tool for many tasks. Its versatility makes it indispensable in many fields.

Choosing The Right Blade

Choosing the right blade for your coping saw is crucial. It can affect the quality of your cuts. There are different blade options depending on the material and type of cut you need. Let’s dive into the details.

Material Types

The material type of the blade is important. Different materials require different blades. Here are some common materials and their matching blades:

| Material | Blade Type |

|---|---|

| Wood | Standard wood blade |

| Plastic | Fine-toothed blade |

| Metal | Hardened steel blade |

Tooth Patterns

Tooth patterns determine the smoothness and speed of your cuts. Here are some common patterns:

- Coarse Teeth: Faster cuts, but rougher edges.

- Fine Teeth: Smoother cuts, but slower.

- Skip Tooth: Good for soft materials, less clogging.

Choosing the right tooth pattern depends on your project needs. For detailed work, use fine teeth. For quick cuts, use coarse teeth.

Understanding these factors will help you select the perfect blade. This ensures your coping saw performs its best.

Step-by-step Guide To Using A Coping Saw

A coping saw is a versatile tool for intricate cuts in wood, plastic, or metal. This guide will help you use a coping saw effectively and safely.

Preparation

Before starting, gather your materials and tools. Ensure your coping saw blade is sharp and properly tensioned.

| Materials | Tools |

|---|---|

| Wood, plastic, or metal | Coping saw |

| Pencil | Workbench |

| Clamps | Safety goggles |

Mark your cutting line with a pencil. Secure your material with clamps on a stable workbench.

Cutting Techniques

- Start the Cut: Place the saw blade on the marked line. Use light, steady strokes.

- Follow the Line: Keep the blade aligned with the marked line. Turn the saw handle slowly for curves.

- Finish the Cut: Complete the cut with gentle strokes. Avoid forcing the blade through the material.

Practice these techniques on scrap material to gain confidence.

Safety Tips

- Wear Safety Goggles: Protect your eyes from debris.

- Keep Hands Clear: Hold the material firmly but keep hands away from the blade.

- Use a Stable Work Surface: Ensure your workbench is secure.

- Blade Tension: Check blade tension regularly to avoid breaks.

By following these steps, you can safely use a coping saw for various projects.

Maintenance And Care

Proper maintenance and care of a coping saw ensure its longevity. It also guarantees precise cuts every time. This section covers essential tips on cleaning, blade replacement, and storage.

Cleaning

Regular cleaning is crucial for a coping saw. Dust and debris can affect its performance. Follow these steps:

- Wipe the blade with a dry cloth after each use.

- Use a soft brush to remove dust from tight spots.

- Apply a light coat of oil to prevent rust.

Blade Replacement

A dull blade can ruin your projects. Replacing it is simple and quick:

- Loosen the tension knob.

- Remove the old blade carefully.

- Insert the new blade, ensuring teeth point towards the handle.

- Tighten the tension knob until the blade is taut.

Storage

Storing your coping saw properly extends its life. Here’s how:

- Hang the saw on a pegboard or store in a toolbox.

- Keep it in a dry place to avoid rust.

- Avoid stacking heavy items on it.

Credit: www.popularwoodworking.com

Comparing Coping Saws To Other Saws

Comparing coping saws to other saws can help you choose the right tool. Each saw has specific uses and advantages. Below, we compare coping saws with jigsaws, hacksaws, and scroll saws.

Jigsaw

A jigsaw is an electric saw with a small, straight blade. It cuts intricate shapes and curves in wood, metal, and plastic. The blade moves up and down quickly. Jigsaws are versatile and easy to use.

- Electric-powered

- Fast cutting

- Best for thick materials

In contrast, a coping saw has a narrow, replaceable blade. It is ideal for detailed work and tight corners. Coping saws are manually operated and provide more control.

Hacksaw

A hacksaw is designed for cutting metal and plastic. It has a straight blade held in a frame. Hacksaws are strong and durable.

| Feature | Coping Saw | Hacksaw |

|---|---|---|

| Blade Type | Thin, replaceable | Thick, replaceable |

| Material | Wood, plastic | Metal, plastic |

| Usage | Intricate cuts | Straight cuts |

The coping saw excels in making curved cuts. Meanwhile, the hacksaw is best for straight cuts in tougher materials.

Scroll Saw

A scroll saw is a stationary saw with a fine blade. It is used for precision work on wood and metal. The blade moves up and down rapidly.

- High accuracy

- Ideal for detailed patterns

- Stationary tool

Compared to a coping saw, a scroll saw is more suitable for complex designs. The coping saw, being handheld, offers greater flexibility and mobility.

Each saw has its strengths. Choose the best one for your project needs.

Credit: home.howstuffworks.com

Frequently Asked Questions

- What Is A Coping Saw?

A coping saw is a hand tool with a thin, narrow blade used for cutting intricate shapes in wood.

- How Does A Coping Saw Work?

The blade is tensioned in a U-shaped frame, allowing precise cuts by pushing or pulling the saw.

- What Materials Can A Coping Saw Cut?

A coping saw can cut wood, plastic, and thin metal, making it versatile for various projects.

- Why Use A Coping Saw For Woodworking?

It allows for detailed, intricate cuts that other saws can’t achieve, making it ideal for fine woodworking.

- How Do You Change A Coping Saw Blade?

Loosen the frame tension, remove the old blade, insert the new one, and re-tighten the frame.

Conclusion

A coping saw is essential for intricate cutting tasks. Its unique design allows for precision and control. Perfect for woodworking and crafts, it handles curves and angles effortlessly.

Invest in a quality coping saw to enhance your DIY projects. Understanding its uses can greatly improve your craftsmanship.