A tenon saw is a hand saw with a stiffened back, primarily used for precise woodworking cuts. It’s ideal for cutting tenons and other fine joinery.

A tenon saw, with its distinct stiffened back, ensures accurate and clean cuts in woodworking. Craftsmen often rely on it for tasks requiring precision, such as creating tenons and other intricate joinery. Its design helps maintain a straight line, reducing the risk of the blade bending during use.

Woodworkers value the tenon saw for its ability to produce smooth and accurate cuts, essential in furniture making and detailed carpentry.

This tool’s reliability and precision make it indispensable in any woodworker’s toolkit, enhancing the quality and craftsmanship of their projects.

Credit: www.quora.com

Introduction To Tenon Saws

A tenon saw is a type of hand saw. It’s commonly used in woodworking. This saw is known for its precision and fine cuts. Carpenters and woodworkers often rely on it. Its unique design makes it ideal for specific tasks.

Definition

A tenon saw has a stiff, straight blade. This blade usually has a reinforced spine. The teeth are finely set for smooth cuts. It’s used to cut wood joints, especially tenons. The reinforced spine prevents bending, ensuring accurate cuts.

Historical Background

The tenon saw dates back to ancient woodworking. It evolved from basic hand tools. Over time, its design improved for better precision. Early craftsmen recognized its value. They used it to create intricate wood joints. This saw became essential in furniture making. Today, it’s still a favorite among woodworkers.

Key Features

A tenon saw is a crucial tool for woodworkers. Understanding its key features helps in selecting the right saw for your needs. Below are the primary characteristics that make a tenon saw unique and effective.

Blade Design

The blade of a tenon saw is rigid and straight. It usually ranges from 8 to 12 inches in length. The blade design features a reinforced spine, known as a back. This back keeps the blade stiff, ensuring precise cuts. The teeth are typically fine and closely spaced. This design allows for smoother and more accurate cuts in hardwoods.

Here is a quick overview of blade features:

- Length: 8 to 12 inches

- Teeth: Fine and closely spaced

- Reinforced Spine: Provides stability

Handle Design

The handle of a tenon saw is designed for comfort and control. It is often made from wood or plastic. The grip is usually closed, allowing for a firm hold. This handle design reduces hand fatigue during long use. The closed handle also offers better control, essential for making accurate cuts.

Key features of the handle include:

- Material: Wood or plastic

- Grip: Closed for a firm hold

- Comfort: Reduces hand fatigue

Types Of Tenon Saws

Tenon saws come in various types, each designed for specific tasks. Understanding these types helps choose the right saw for your woodworking project. Here, we’ll explore two main types: rip-cut tenon saws and cross-cut tenon saws.

Rip-cut Tenon Saws

Rip-cut tenon saws are used for cutting along the grain. They have fewer teeth per inch (TPI), usually around 5-7 TPI. This design allows the saw to cut faster and more aggressively.

- Teeth Design: The teeth are shaped like chisels.

- Usage: Ideal for making long, straight cuts.

- Material: Typically made of high-carbon steel.

Rip-cut tenon saws are perfect for creating deep, straight cuts in wood. These saws are essential for projects requiring precise long cuts.

Cross-cut Tenon Saws

Cross-cut tenon saws are used for cutting across the grain. They have more teeth per inch, usually around 10-14 TPI. This makes for a smoother cut.

- Teeth Design: The teeth are beveled, acting like knives.

- Usage: Great for making clean, precise cuts.

- Material: Often made from tempered steel.

Cross-cut tenon saws are essential for tasks requiring neat, clean cuts. They are perfect for cutting wood pieces to length.

| Type | Teeth Per Inch (TPI) | Best For |

|---|---|---|

| Rip-Cut Tenon Saws | 5-7 TPI | Cutting along the grain |

| Cross-Cut Tenon Saws | 10-14 TPI | Cutting across the grain |

Choosing the right tenon saw depends on the type of cut you need. Both rip-cut and cross-cut tenon saws are invaluable in woodworking.

Credit: www.lie-nielsen.com

Primary Uses

The tenon saw is an essential tool in woodworking. It’s used for precise, clean cuts. These saws are perfect for intricate jobs. Their stiff back ensures straight cuts. Let’s explore its primary uses below.

Joinery Work

Joinery work needs precision. The tenon saw excels here. It’s ideal for cutting tenons and mortises. These are joints in wood. The saw’s stiff back helps control depth and angle. This results in accurate cuts. Woodworkers use it for making strong joints. These joints hold furniture and structures together.

Furniture Making

Furniture making demands accuracy. The tenon saw is perfect for this. It cuts cleanly through hardwoods. This is important for making tight-fitting joints. Furniture like tables, chairs, and cabinets benefit from this precision. The saw’s stiff back ensures straight cuts. This leads to beautifully crafted furniture.

Advantages Of Using Tenon Saws

A tenon saw is a specialized tool used in woodworking. It offers various benefits, making it a favorite for many woodworkers.

Precision

Tenon saws have a stiff back, ensuring precise cuts. The sharp teeth allow for clean and accurate cuts. This precision is essential for creating tight joints in wood projects.

Using a tenon saw reduces errors, saving time and materials. Woodworkers can create detailed designs with ease.

Control

Tenon saws provide excellent control over cutting. The rigid blade minimizes wobbling, allowing for straight cuts. Woodworkers can handle the saw comfortably, reducing strain.

The design of the tenon saw makes it perfect for intricate tasks. It is ideal for cutting small pieces and detailed work.

| Feature | Benefit |

|---|---|

| Stiff Back | Ensures precision |

| Sharp Teeth | Clean cuts |

| Rigid Blade | Enhanced control |

- Reduces errors in cutting

- Ideal for intricate tasks

- Comfortable to handle

How To Choose A Tenon Saw

Choosing the right tenon saw is crucial for woodworking projects. The right saw ensures precise and clean cuts. Here’s how to choose the perfect tenon saw for your needs.

Blade Material

The blade material affects the saw’s performance and durability. Common materials include high-carbon steel and stainless steel. High-carbon steel blades are sharp and stay sharp longer. Stainless steel blades resist rust and corrosion. Consider your environment and project needs when selecting a blade material.

Teeth Per Inch

The number of teeth per inch (TPI) determines the smoothness of the cut. A higher TPI means finer cuts, suitable for detailed work. A lower TPI is better for rough cuts. Here’s a quick guide:

- 14-20 TPI: Fine cuts, ideal for hardwoods and detailed work.

- 8-12 TPI: General-purpose cuts, suitable for most woods.

- 4-7 TPI: Rough cuts, best for softwoods and fast cutting.

Choose the TPI based on your project requirements. A higher TPI provides a smoother finish, while a lower TPI cuts faster.

| Teeth Per Inch (TPI) | Best Use |

|---|---|

| 14-20 TPI | Hardwoods, detailed work |

| 8-12 TPI | General-purpose |

| 4-7 TPI | Softwoods, fast cutting |

Maintenance Tips

Proper maintenance of your tenon saw ensures it remains effective and lasts longer. Regular care includes sharpening and cleaning. Let’s explore these in detail.

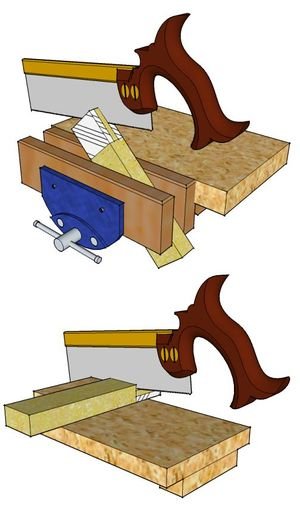

Sharpening

Sharpening your tenon saw is crucial. A sharp blade cuts wood smoothly and safely.

- Use a fine-toothed file for sharpening.

- Secure the saw in a vise to keep it steady.

- File each tooth individually, maintaining the original angle.

- Check for evenness after sharpening.

Cleaning

Cleaning your tenon saw prevents rust and buildup. This keeps the blade in good condition.

- Wipe the blade with a dry cloth after use.

- Use a brush to remove debris from the teeth.

- Apply a light coat of oil to prevent rust.

- Store the saw in a dry place.

Maintaining your tenon saw with these simple steps can significantly enhance its lifespan and performance.

Safety Tips

Using a tenon saw can be very efficient for woodwork. But it can also be dangerous if not used properly. Here are some essential safety tips to ensure you stay safe while using a tenon saw.

Proper Handling

Always hold the tenon saw with both hands. Keep your hands dry and free from oil. Ensure a firm grip on the handle to prevent slipping. Use smooth, controlled strokes when cutting. Avoid forcing the saw through the wood. Let the blade do the work.

Protective Gear

Wearing the right protective gear is crucial. Always wear safety goggles to protect your eyes from wood chips. Use gloves to protect your hands from splinters and cuts. A dust mask can help prevent inhalation of sawdust.

Here is a quick checklist:

- Safety goggles: Protects eyes from debris

- Gloves: Shields hands from injuries

- Dust mask: Prevents inhaling harmful particles

Credit: www.youtube.com

Frequently Asked Questions

- What Is A Tenon Saw?

A tenon saw is a hand saw with a stiffened back, designed for precise wood cutting.

- Why Use A Tenon Saw?

Use a tenon saw for accurate, clean cuts in woodworking projects, especially for joints.

- How Is A Tenon Saw Different?

A tenon saw has a reinforced back, allowing for straight, controlled cuts.

- What Materials Does A Tenon Saw Cut?

Tenon saws are ideal for cutting hardwoods, softwoods, and composite woods.

- Can Beginners Use A Tenon Saw?

Yes, beginners can easily use a tenon saw due to its precision and control.

Conclusion

A tenon saw is essential for precise woodworking tasks. It ensures accurate cuts and fine finishes. Whether you’re a professional or hobbyist, this tool is invaluable.

Investing in a quality tenon saw can greatly enhance your woodworking projects. Understanding its use and benefits makes your work more efficient and enjoyable.