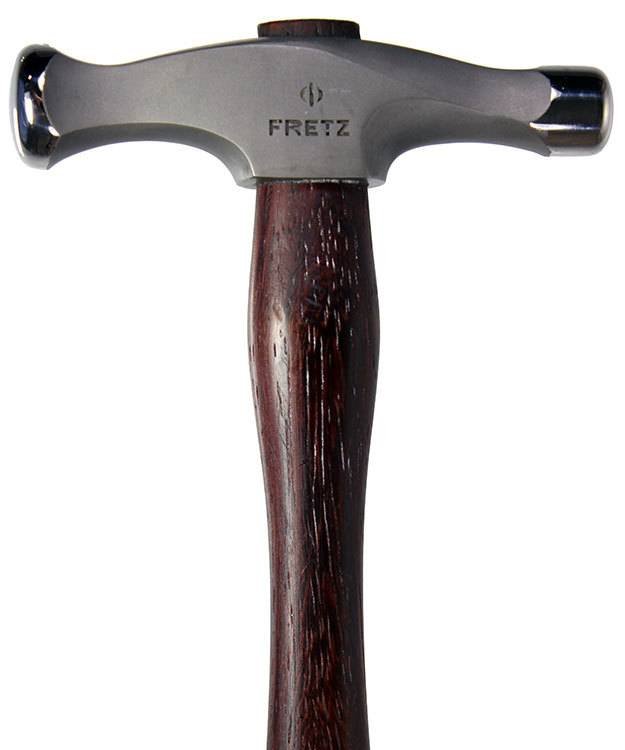

A blocking hammer is a metalworking tool used for shaping and forming metal sheets. It features a flat, broad face for pounding and smoothing.

A blocking hammer is essential in metalworking, particularly for blacksmiths and artisans. This versatile tool helps shape metal sheets into desired forms.

Its flat, broad face is ideal for pounding, smoothing, and stretching metal. With a comfortable handle, it provides control and precision.

Artisans often use it to create curves and detailed shapes in metalworking projects. The blocking hammer’s design ensures even distribution of force, reducing the risk of damaging the metal.

Its efficiency and reliability make it a favorite among metalworkers for both small-scale and large-scale projects.

Credit: www.amazon.com

Introduction To The Blocking Hammer

The blocking hammer is a versatile tool in metalworking. It is essential for shaping and forming metal sheets. This tool has a rich history and a simple design that makes it effective.

Origins

The origins of the blocking hammer date back to ancient times. Blacksmiths and metalworkers have used similar tools for centuries. It has evolved over time but its basic purpose remains the same.

In the past, blacksmiths crafted blocking hammers by hand. They used iron and steel to create these tools. Today, modern manufacturing processes produce more precise and durable hammers.

Basic Design

The blocking hammer has a straightforward design. It consists of a handle and a heavy head. The head has two flat faces for striking and shaping metal.

| Component | Description |

|---|---|

| Handle | Usually made of wood or fiberglass for strength. |

| Head | Heavy and flat, made of steel or iron. |

| Faces | Flat surfaces on the head for striking metal. |

The handle provides a comfortable grip. It allows for control and precision. The heavy head delivers powerful strikes. This enables effective shaping of metal sheets.

There are different sizes of blocking hammers. Some are lightweight for delicate work. Others are heavier for more demanding tasks.

Credit: www.reddit.com

Key Features

The blocking hammer is an essential tool for metalworking. Its key features determine its efficiency and user-friendliness. Below, we explore two crucial features of the blocking hammer: Material and Weight and Balance.

Material

The material of a blocking hammer affects its durability. Most blocking hammers are made from high-quality steel. This ensures they can withstand heavy use. Some hammers also have wooden or fiberglass handles. These materials provide a comfortable grip. Wooden handles absorb shock better. Fiberglass handles are more durable and resistant to wear.

Weight And Balance

The weight and balance of a blocking hammer are critical. A well-balanced hammer reduces fatigue. Most blocking hammers weigh between 1 to 3 pounds. Lighter hammers are easier to handle for longer periods. Heavier hammers deliver stronger blows. The balance depends on the distribution of weight. A balanced hammer has its weight evenly distributed. This makes it easier to control and use precisely.

Types Of Blocking Hammers

Blocking hammers come in different types. Each type has a unique purpose. Understanding these types helps in selecting the right tool for your project. Below are some common types of blocking hammers you might encounter.

Flat Face

The Flat Face blocking hammer has a smooth, flat striking surface. This type of hammer is ideal for flattening and shaping metal sheets. It ensures even pressure across the surface, reducing the risk of dents or imperfections.

- Useful for smoothing surfaces

- Helps in shaping metal sheets

- Reduces the risk of dents

Flat Face hammers are essential in metalworking. They provide a clean, even finish. This makes them perfect for detailed work.

Rounded Face

The Rounded Face blocking hammer features a curved striking surface. This design is perfect for creating curves and rounded shapes in metal. The rounded face allows for more control over the shape.

- Ideal for creating curves

- Offers better control for shaping

- Prevents sharp edges

Rounded Face hammers are crucial for projects requiring smooth, curved shapes. They help in forming consistent, rounded surfaces, making them a valuable tool in any metalworking toolkit.

Applications In Metalworking

The blocking hammer is a versatile tool in metalworking. It serves various applications that are crucial for metal shaping and repair. Here we explore its primary uses.

Shaping Metal

The blocking hammer is essential for shaping metal. It is commonly used to create smooth, curved surfaces. The hammer’s face is designed to distribute force evenly. This helps in achieving the desired shape without damaging the metal.

Artisans and metalworkers often rely on it for forming bowls, trays, and other curved objects. The blocking hammer allows for precise control. This ensures that the final product meets exact specifications. In workshops, it is a go-to tool for custom metal projects.

Removing Dents

Another critical application of the blocking hammer is removing dents. It is effective in straightening metal surfaces. The hammer can restore the original shape of damaged metal sheets. This is particularly useful in automotive repair shops.

Using a blocking hammer, technicians can gently tap out imperfections. This process minimizes further damage. As a result, it helps maintain the integrity of the metal. The hammer’s design makes it ideal for detailed work. It ensures the surface remains smooth after dent removal.

Techniques For Effective Use

Mastering the blocking hammer requires specific techniques. These techniques ensure efficiency and safety. Let’s explore the key methods for using a blocking hammer effectively.

Grip And Stance

Your grip on the hammer is crucial. Hold the hammer firmly but not too tight. This allows control and reduces fatigue. Place your thumb along the handle for better guidance.

Next, focus on your stance. Stand with your feet shoulder-width apart. This stance provides balance and stability. Bend your knees slightly for better movement and control.

Striking Methods

There are different striking methods to use. The basic strike is a simple downward motion. This method is effective for general tasks.

For more precision, use the glancing blow. This involves striking at an angle. It helps in shaping and detailing workpieces.

Another technique is the dead blow. This method minimizes rebound. Use it when you need to apply force without bouncing back.

| Striking Method | Use |

|---|---|

| Basic Strike | General tasks |

| Glancing Blow | Shaping and detailing |

| Dead Blow | Force without rebound |

Remember to always wear safety gear. This includes gloves and eye protection. Safety first ensures a successful project.

Safety Precautions

Using a blocking hammer requires strict safety measures. This ensures your protection and efficiency. Below are some key safety precautions to follow.

Protective Gear

Wearing the right protective gear is essential. Always use a sturdy pair of work gloves to protect your hands. Safety goggles shield your eyes from flying debris. A hard hat is necessary to safeguard your head. Consider using ear protection if the work area is noisy.

- Work gloves

- Safety goggles

- Hard hat

- Ear protection

Safe Work Environment

Maintain a safe work environment at all times. Clear the area of any trip hazards. Ensure your workspace is well-lit and ventilated. Keep a first aid kit nearby in case of emergencies.

| Safety Tip | Importance |

|---|---|

| Clear trip hazards | Prevents falls |

| Good lighting | Improves visibility |

| Ventilation | Removes fumes |

| First aid kit | Immediate care |

Follow these safety precautions to use a blocking hammer safely. Your well-being should always come first.

Maintaining Your Blocking Hammer

To extend the life of your blocking hammer, regular maintenance is key. Proper care ensures it remains effective and safe to use.

Cleaning Tips

Clean your blocking hammer after each use. Dirt and debris can cause damage over time.

- Wipe the hammer head with a damp cloth.

- Use mild soap for stubborn stains.

- Dry it thoroughly to prevent rust.

Inspect the handle for signs of wear. A damaged handle can be dangerous.

- Check for cracks or splinters.

- Sand down rough areas.

- Apply a wood conditioner to wooden handles.

Storage Advice

Store your blocking hammer in a dry place. Moisture can cause rust and damage.

- Hang it on a tool rack.

- Keep it in a toolbox with a lid.

- Avoid leaving it on the ground.

Use a protective cover if possible. This adds an extra layer of protection.

- Ensure the cover is dry before use.

- Replace the cover if it becomes worn.

Credit: contenti.com

Frequently Asked Questions

- What Is A Blocking Hammer?

A blocking hammer is a metalworking tool used for shaping and forming metal sheets.

- How Is A Blocking Hammer Used?

A blocking hammer is used to pound and shape metal over a form or block.

- What Materials Are Blocking Hammers Made From?

Blocking hammers are typically made from hardened steel to withstand heavy use in metalworking.

- Can Beginners Use A Blocking Hammer?

Yes, beginners can use a blocking hammer with proper guidance and practice.

- Where Can I Buy A Blocking Hammer?

You can buy blocking hammers at hardware stores, online marketplaces, and specialized metalworking shops.

Conclusion

A blocking hammer is an essential tool for shaping and forming metal. It’s widely used in metalworking and jewelry making. Understanding its use can enhance your craftsmanship.

Incorporate a blocking hammer into your toolkit to achieve precise and professional results.

Mastering this tool will elevate your projects to new heights.