Your employer must have safety cages or wells on fixed ladders. They must also provide fall protection systems.

Fixed ladders are essential in many workplaces. They allow access to high areas. Safety is crucial when using these ladders. Employers must ensure fixed ladders have safety cages or wells. This protects workers from falls. Fall protection systems are also a must.

These systems catch workers if they slip. Ensuring these safety measures reduces accidents. It keeps workers safe and productive. Always check your ladder for these features. Safety is everyone’s responsibility. Proper equipment can save lives. Employers must comply with these safety standards. Workers should also be aware of them. Always prioritize safety on fixed ladders.

Credit: quizlet.com

Introduction To Fixed Ladder Safety

Fixed ladders are common in many workplaces. They provide access to high areas. Ensuring safety on these ladders is crucial. Without safety measures, accidents can happen. Employers must follow specific rules to keep workers safe.

Importance Of Safety Measures

Safety measures protect workers. They prevent falls and injuries. Employers must install safety devices on fixed ladders. These include cages, wells, and platforms. Regular inspections are also necessary. Inspections spot wear and tear early. This keeps ladders in good condition. Training workers on ladder safety is key. They should know how to use ladders properly.

Common Safety Risks

Fixed ladders come with risks. Falls are the most common. Workers can slip or lose balance. Improper use of ladders can lead to accidents. Overloading ladders is another risk. Ladders have a weight limit. Exceeding this limit can cause them to break.

| Risk | Cause |

|---|---|

| Falls | Slips, trips, and loss of balance |

| Improper Use | Incorrect climbing techniques |

| Overloading | Exceeding weight limits |

Follow these safety tips to reduce risks:

- Use ladders as intended.

- Do not overload ladders.

- Inspect ladders regularly.

- Train workers on ladder safety.

Regulatory Requirements

Understanding the regulatory requirements for fixed ladders is essential for workplace safety. Employers must comply with specific standards to ensure the safety of their employees. This section will delve into the key regulatory aspects that businesses must adhere to.

Osha Standards

The Occupational Safety and Health Administration (OSHA) sets strict guidelines for fixed ladders. These standards are designed to minimize the risk of accidents and injuries.

- Fixed ladders over 24 feet must have a fall protection system.

- All ladders must be capable of supporting their maximum intended load.

- Ladder rungs must be at least 16 inches wide.

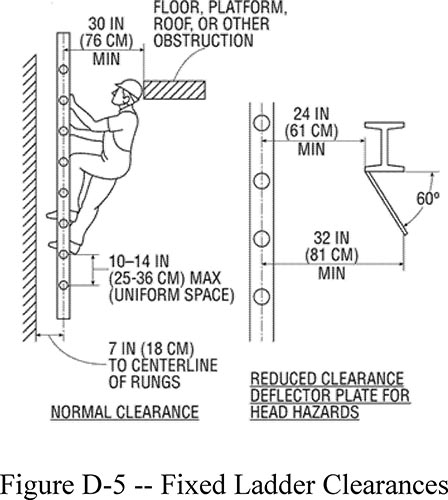

- The distance between rungs should be uniform and between 10 to 14 inches.

Compliance Guidelines

Employers should follow these compliance guidelines to meet OSHA standards and ensure worker safety:

- Conduct regular inspections of all fixed ladders.

- Ensure proper training for all employees using ladders.

- Install safety features such as ladder safety devices.

- Maintain clear signage indicating ladder usage guidelines.

Employers must also document all inspections and training sessions. This documentation is crucial for proving compliance with OSHA standards.

| Requirement | Description |

|---|---|

| Fall Protection | Required for ladders over 24 feet |

| Load Capacity | Must support maximum intended load |

| Rung Width | At least 16 inches |

| Rung Spacing | Between 10 to 14 inches |

Adhering to these regulations is not just a legal requirement. It also ensures a safer working environment. Employers should prioritize these guidelines to protect their workforce and avoid penalties.

Structural Integrity

Structural integrity is critical for fixed ladders in the workplace. Employers must ensure ladders are safe and reliable. This prevents accidents and injuries. Two key aspects of structural integrity are material specifications and load-bearing capacity.

Material Specifications

Fixed ladders must be made from durable materials. Common materials include steel, aluminum, and fiberglass. Each material has unique properties:

- Steel: Very strong and durable. Resistant to wear and tear.

- Aluminum: Lightweight and corrosion-resistant. Easy to install.

- Fiberglass: Non-conductive. Ideal for electrical environments.

Employers should choose the right material for the ladder’s intended use. Material choice impacts the ladder’s safety and longevity.

Load-bearing Capacity

Load-bearing capacity refers to the maximum weight a ladder can support. This includes the weight of the user and any carried tools. Employers must ensure ladders meet specific load requirements.

Key points to consider for load-bearing capacity:

- Calculate the maximum load the ladder will bear.

- Choose a ladder with a higher load capacity than the calculated maximum.

- Regularly inspect ladders for signs of stress or damage.

Employers must ensure that fixed ladders are strong enough to support expected loads. This is crucial for preventing accidents.

Credit: www.osha.gov

Fall Protection Systems

Fixed ladders pose significant risks if not properly secured. Fall protection systems ensure worker safety. These systems are crucial for preventing accidents and injuries.

Guardrails And Cages

Guardrails and cages offer essential protection on fixed ladders. Guardrails are sturdy barriers installed along the ladder’s sides. They prevent workers from falling off the ladder.

Cages surround the ladder, providing an extra layer of safety. They act as a protective barrier and reduce fall risks. Cages also offer a secure climbing environment.

| Component | Description |

|---|---|

| Guardrails | Barriers installed along ladder sides. |

| Cages | Enclosures around ladders for added safety. |

Personal Fall Arrest Systems

Personal fall arrest systems are vital for worker safety. These systems include a body harness, anchorage, and connectors. They prevent workers from hitting the ground during a fall.

Key components of personal fall arrest systems include:

- Body harness: Worn by the worker, it distributes fall forces.

- Anchorage: A secure point to attach the system.

- Connectors: Links the harness to the anchorage.

These systems are designed to stop falls quickly and safely. They are essential for compliance with safety regulations.

Inspection And Maintenance

Fixed ladders are vital for workplace safety. Regular inspection and maintenance ensure their reliability. Employers must prioritize these practices to prevent accidents and injuries.

Regular Inspection Protocols

Employers should establish regular inspection protocols for fixed ladders. These inspections should be performed by trained personnel. The following points highlight key aspects:

- Inspect ladders monthly for any visible damage.

- Check for rust, cracks, and loose rungs.

- Ensure the ladder is securely anchored.

- Verify that all safety features are functional.

Documentation of each inspection is crucial. It helps track the ladder’s condition over time. A sample inspection checklist could include:

| Inspection Item | Condition | Comments |

|---|---|---|

| Rungs | Good/Fair/Poor | Note any defects |

| Anchors | Good/Fair/Poor | Note any looseness |

| Safety Features | Good/Fair/Poor | Check functionality |

Maintenance Best Practices

Proper maintenance extends the life of fixed ladders. Adhering to best practices ensures safety. Key maintenance practices include:

- Lubricate moving parts to prevent rust.

- Tighten any loose bolts or fasteners.

- Replace any worn-out or damaged parts.

- Apply anti-slip coatings to rungs and steps.

Maintenance should be performed by qualified personnel. They must have the right tools and knowledge. Consistent maintenance reduces the risk of accidents.

Employers must keep a detailed record of all maintenance activities. This ensures accountability and helps in planning future maintenance schedules.

Credit: simplifiedsafety.com

Training And Awareness

Understanding safety on fixed ladders is crucial. Employers must ensure employees are aware of the risks. Proper training programs and safety drills play a vital role. This section will cover essential training and awareness practices.

Employee Training Programs

Employers must offer comprehensive training programs for fixed ladder safety. These programs should include:

- Understanding ladder safety rules.

- Proper climbing techniques.

- Identifying potential hazards.

- Using safety equipment correctly.

Training should be updated regularly. This helps employees stay aware of new safety standards and practices.

Safety Drills And Exercises

Regular safety drills and exercises are essential. These drills help employees react quickly in emergencies. Key elements of effective safety drills include:

- Simulating real-life scenarios.

- Practicing emergency evacuation procedures.

- Testing safety equipment.

- Reviewing drill outcomes to improve safety measures.

Conducting these drills frequently ensures everyone knows their role. This enhances the overall safety environment.

Frequently Asked Questions

What Are The Safety Requirements For Fixed Ladders?

Employers must ensure fixed ladders are secure, stable, and have proper fall protection systems.

Do Fixed Ladders Need Cages?

Cages are required for fixed ladders over 24 feet to prevent falls and ensure safety.

Are Ladder Inspections Mandatory?

Yes, regular inspections are mandatory to ensure the ladder’s safety and compliance with OSHA standards.

What Is The Maximum Height For Fixed Ladders?

Fixed ladders can be installed up to 24 feet without requiring fall protection systems.

Do Fixed Ladders Need A Rest Platform?

Rest platforms are required every 150 feet to prevent fatigue and ensure user safety.

Conclusion

Employers must ensure fixed ladders are safe and compliant. Regular inspections and maintenance are crucial. Safety features like cages and guardrails are essential. Proper training for employees using ladders is important. Following these guidelines helps prevent accidents. Keep your workplace safe and up to standards.