Every defective ladder should have clear warning labels. These warnings ensure safety and prevent accidents.

A defective ladder can be dangerous. It may lead to serious injuries if used. Proper labeling helps identify these risks. Ladders are common tools in homes and workplaces. They help us reach high places safely. But what if a ladder is defective?

Using it could be risky. Clear labels on defective ladders are crucial. They inform users of potential dangers. This blog will discuss what should be written on all defective ladders. It will help you understand the importance of proper labeling. Stay safe by knowing the right information to look for.

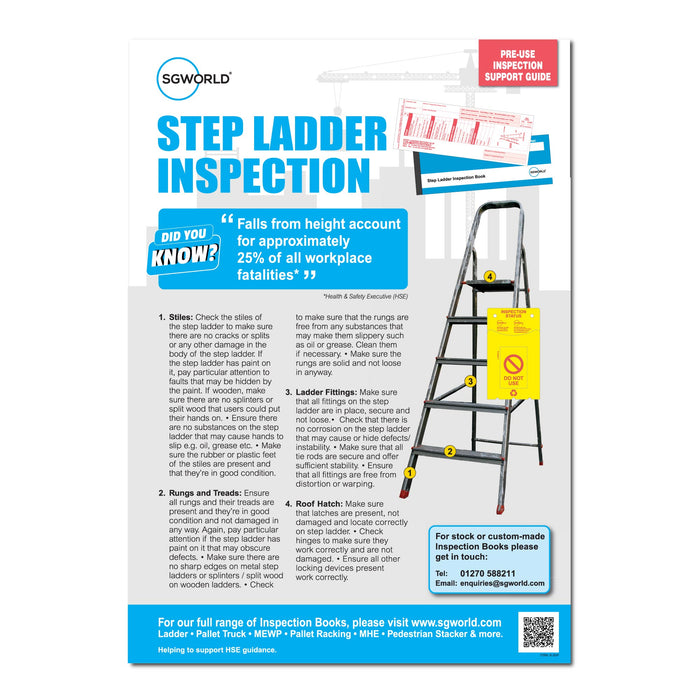

Credit: www.sgworld.com

Safety Warnings

Writing safety warnings on defective ladders is crucial. It helps prevent accidents and injuries. Proper labeling ensures everyone understands the risks. This section covers essential aspects of safety warnings.

Visible Labels

All defective ladders must have visible labels. These labels should be easy to spot. Use bright colors like red or yellow. Place labels at eye level. This ensures they are not missed. Consider using large fonts for clarity.

Labels should include the word “defective” prominently. Also, mention that the ladder should not be used. This helps in avoiding any misunderstandings. Make sure the labels are weather-resistant. This ensures they stay intact in different conditions.

Clear Wording

Use clear wording on all safety warnings. Avoid technical jargon. Simple language ensures everyone understands. For instance, use “Do not use” instead of complicated phrases.

Here are some examples of clear safety warnings:

- Danger: Defective Ladder

- Warning: Do Not Use

- Caution: Risk of Injury

Ensure the text is short and to the point. Avoid cluttering the label with too much information. A clear and concise message works best.

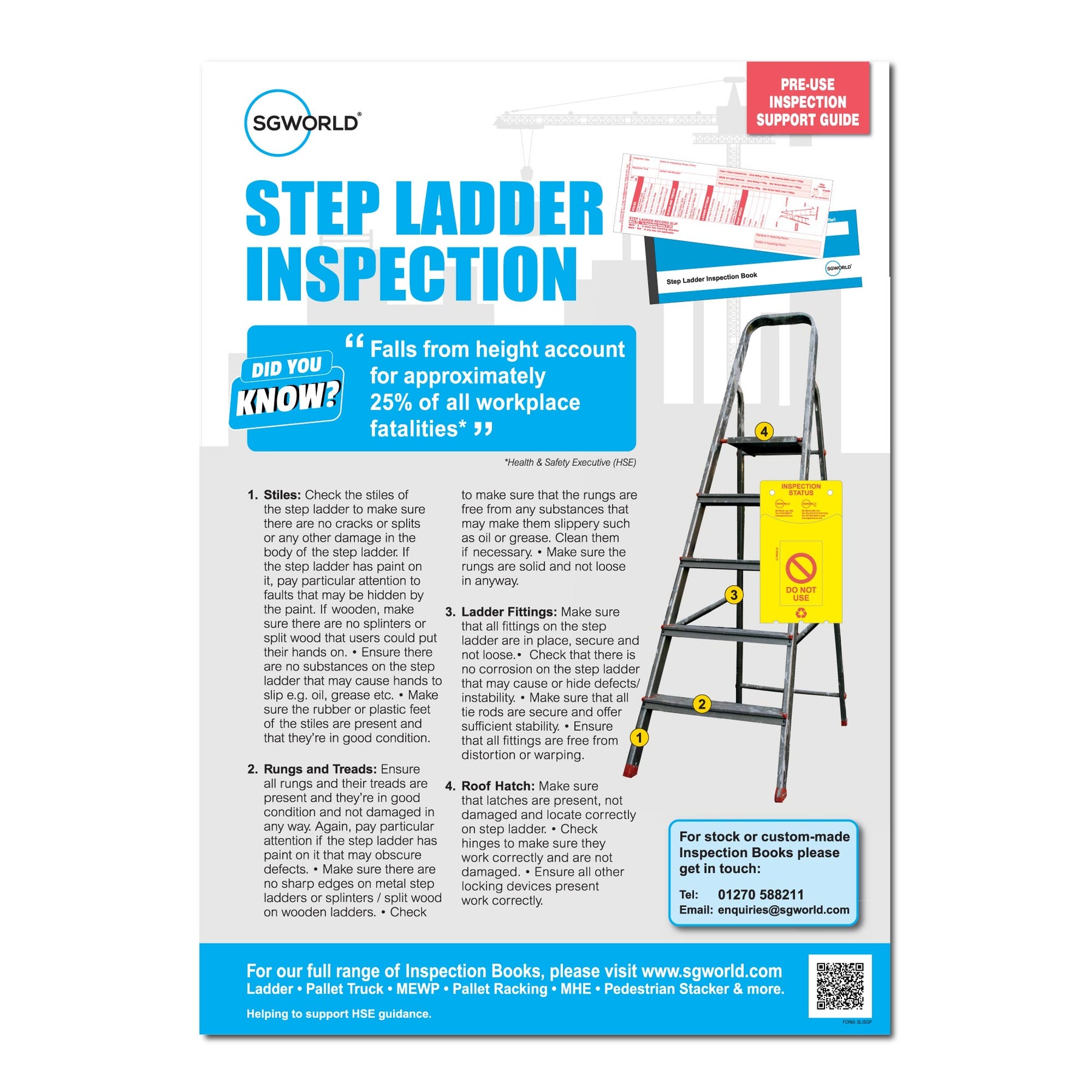

Credit: www.sgworld.com

Inspection Procedures

Inspection Procedures are vital for maintaining the safety and functionality of ladders. Regular checks help identify defects early. This ensures that no one uses a ladder that could cause injury. Detailed documentation of each inspection provides a record of the ladder’s condition over time.

Regular Checks

Conduct regular checks to spot any defects in ladders. These checks should include:

- Visual inspection for cracks or bends.

- Checking the stability of all steps.

- Ensuring that all screws and bolts are tight.

- Inspecting for any rust or corrosion.

Perform these checks before each use. This can prevent accidents. Use a checklist to make sure nothing is missed. Regular checks can extend the life of the ladder. This makes it safer for everyone.

Detailed Documentation

Detailed documentation is crucial for tracking the condition of ladders. Keep a record of each inspection. This should include:

| Date | Inspector Name | Condition | Notes |

|---|---|---|---|

| MM/DD/YYYY | John Doe | Good | No issues found. |

| MM/DD/YYYY | Jane Smith | Fair | Minor rust on steps. |

Documenting each inspection helps track wear and tear. It also provides proof of regular maintenance. This can be helpful if an accident occurs. Detailed documentation can also help identify patterns. For example, if a particular part of the ladder is frequently damaged.

Proper Storage

Storing defective ladders correctly is essential for workplace safety. Ignoring proper storage can lead to accidents. This section will guide you on how to store defective ladders effectively.

Designated Areas

Always store defective ladders in designated areas. These areas should be separate from functional ladders. This helps in easy identification and reduces the risk of accidental use.

Create a specific zone within your storage area. Label this zone clearly with signs indicating it is for defective ladders. Ensure everyone in the workplace knows this location.

Preventing Use

Prevent the use of defective ladders by marking them clearly. Use bright colored tags or labels that read “Do Not Use”. This warning should be visible from a distance.

Additionally, consider using physical barriers. Place barriers around the storage area to further prevent access. This adds an extra layer of safety.

| Storage Tip | Description |

|---|---|

| Designated Areas | Separate defective ladders from functional ones. |

| Clear Labels | Use bright tags with “Do Not Use” warnings. |

| Physical Barriers | Use barriers to restrict access to defective ladders. |

- Store defective ladders in designated areas.

- Use clear labels to mark defective ladders.

- Employ physical barriers for added safety.

By following these steps, you ensure the defective ladders are stored properly. This minimizes the risk of accidents and maintains a safe working environment.

Employee Training

Employee training is crucial for maintaining a safe workplace. Proper training ensures employees know how to handle tools, including defective ladders. This section focuses on the importance of training employees on safety protocols and handling defective equipment.

Safety Protocols

Effective safety protocols are vital. Employees must know how to identify and manage defective ladders. Training should cover:

- Regular inspections

- Reporting defects

- Proper labeling of defective ladders

Regular inspections help in early defect detection. Employees should inspect ladders before use. Reporting defects immediately is essential. This prevents accidents and injuries. Labeling defective ladders clearly is necessary. It informs others not to use them.

Handling Defective Equipment

Handling defective equipment requires specific steps. Employees must follow these steps to ensure safety:

- Identify the defect

- Report it to a supervisor

- Label the ladder as “Defective”

- Remove it from service

Identifying the defect is the first step. Look for cracks, bends, or missing parts. Reporting to a supervisor ensures that proper action is taken. Labeling the ladder as “Defective” informs others. Removing it from service is crucial. It prevents further use and potential accidents.

Employee training should include practical demonstrations. Visual aids and hands-on practice improve understanding. Training sessions should be interactive and engaging. Use real-life scenarios to illustrate points. Regular refresher courses are important. They keep safety protocols fresh in employees’ minds.

Regulatory Compliance

Ensuring regulatory compliance is crucial for workplace safety. Defective ladders pose a significant risk. They must be clearly marked to prevent use and accidents. This section covers the essential standards and policies for marking defective ladders.

Osha Standards

The Occupational Safety and Health Administration (OSHA) sets clear guidelines for ladder safety. According to OSHA, all defective ladders must be marked with the following:

- “Danger”

- “Do Not Use”

- “Defective”

Proper labeling ensures employees recognize and avoid defective ladders. OSHA also requires that defective ladders be removed from service until repaired or replaced. Regular inspections are mandated to identify defects promptly.

Company Policies

Beyond OSHA standards, each company should have its own policies. These policies should align with OSHA but also address specific workplace needs. Consider the following elements:

- Inspection Schedules: Regular checks for ladder defects.

- Training Programs: Educate employees on identifying and reporting defective ladders.

- Clear Labeling: Ensure all defective ladders are marked per OSHA guidelines.

- Reporting Protocols: Procedures for employees to report defective ladders.

Effective policies enhance safety and compliance. They also foster a culture of proactive hazard management. Ensure all employees are aware of these policies and follow them diligently.

Credit: anthonycarbonepersonalinjurylawyer.com

Frequently Asked Questions

What Should Be Written On Defective Ladders?

A warning label should be placed. It must read “Do Not Use” in bold letters.

Why Do Defective Ladders Need Labels?

Labels warn users. They prevent accidents and injuries. Clear warnings ensure everyone sees the danger.

Where Should The Warning Label Be Placed?

Place the label on the steps and sides. Make sure it’s easy to see.

How Often Should Ladder Inspections Occur?

Inspect ladders before each use. Regular checks help identify defects early.

Can Defective Ladders Be Repaired?

Only if repairs make them safe. Consult a professional to assess the damage first.

What Are Common Defects In Ladders?

Cracks, loose steps, and bent parts. Worn-out hinges and broken locks are also common.

Conclusion

Clear labeling on defective ladders is crucial for safety. Warning signs must be visible. This prevents accidents and ensures proper usage. Simple labels can save lives. Always check ladders for labels before use. Report unlabeled defective ladders immediately. Safety first, always.