For sheet metal cutting, a circular saw with a blade diameter of 7.25 inches is ideal. A saw with a higher RPM rating will provide better performance.

Cutting sheet metal requires the right tools to ensure precision and safety. A circular saw is a versatile option that can handle various materials, including metal. Selecting the appropriate size and blade type is crucial for achieving clean cuts without warping or damaging the material.

Choosing a saw with a 7. 25-inch blade ensures you have the power needed to cut through different gauges of sheet metal effectively. This size offers a balance between maneuverability and cutting depth, making it suitable for both DIY enthusiasts and professionals. Understanding these factors will enhance your cutting experience and improve your project outcomes.

Credit: store.evolutionpowertools.com

Choosing The Right Circular Saw For Metal

Choosing the right circular saw is crucial for cutting sheet metal effectively. The saw must handle the specific thickness and type of metal. This guide helps you make the best choice.

Types Of Circular Saws

Different types of circular saws suit various metal cutting tasks. Here are the main types:

- Standard Circular Saw: Great for general cutting tasks.

- Metal Cutting Circular Saw: Specifically designed for metal, using specialized blades.

- Chop Saw: Offers precision cuts for thicker metals.

- Band Saw: Ideal for intricate cuts and curves.

Key Features To Look For

Several features enhance the efficiency of circular saws for metal cutting:

| Feature | Description |

|---|---|

| Blade Type | Choose carbide-tipped blades for durability and precision. |

| RPM | Higher RPM means faster cuts. Look for at least 3,000 RPM. |

| Weight | A lighter saw is easier to maneuver but stable enough for accuracy. |

| Safety Features | Look for blade guards and electric brakes for safety. |

Consider these factors carefully. They impact cutting efficiency and safety. Choose wisely to achieve the best results.

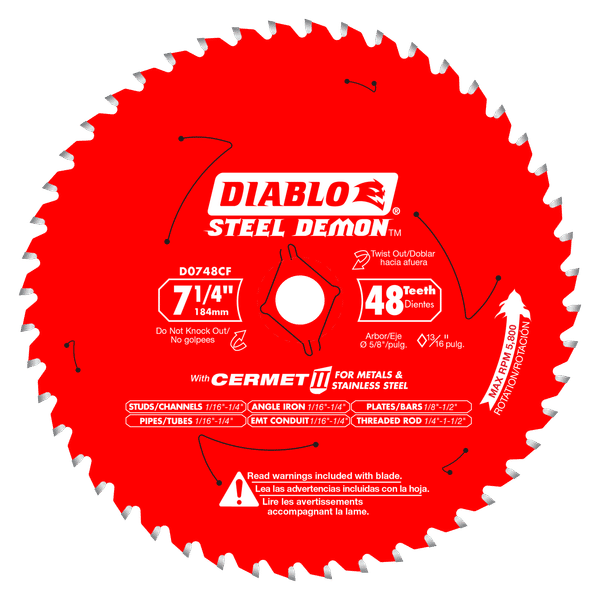

Credit: www.diablotools.com

Blade Size Matters

Choosing the right blade size is crucial for cutting sheet metal. A suitable blade enhances precision and efficiency. It also ensures safety during the cutting process.

Common Blade Sizes

Different sizes of blades cater to various cutting needs. Here are some common blade sizes for circular saws:

| Blade Size | Typical Use |

|---|---|

| 7-1/4 inches | General metal cutting |

| 10 inches | Thicker metal sheets |

| 12 inches | Heavy-duty metal work |

Each size serves different purposes. Selecting the correct size ensures effective cutting.

Matching Blade To Material Thickness

Material thickness determines the blade size needed. Thicker materials require larger blades. Here’s a simple guide:

- Up to 1/16 inch: Use 7-1/4 inch blade.

- 1/16 inch to 1/8 inch: Use 10 inch blade.

- Over 1/8 inch: Use 12 inch blade.

Understanding the thickness of the sheet metal helps in choosing the right blade. Proper matching prevents damage to both the blade and material.

Blade Material And Type

Choosing the right blade material and type is vital for cutting sheet metal. The blade influences the quality of your cuts and the tool’s longevity. Understanding the different types of blades helps you make the best choice.

Carbide-tipped Blades

Carbide-tipped blades are popular for cutting sheet metal. They feature tips made from tungsten carbide, which is very hard. This hardness allows them to cut through tough materials easily.

- Long-lasting performance

- Sharpness retains longer

- Suitable for various metals

Carbide-tipped blades offer precise cuts. They reduce the risk of chipping or breaking. This type of blade is ideal for heavy-duty tasks. Consider the following:

| Feature | Benefit |

|---|---|

| Durability | Lasts longer than regular steel blades |

| Versatility | Works well on aluminum, steel, and other metals |

| Cost | Higher upfront cost but saves money long-term |

Abrasive Blades

Abrasive blades are another option for sheet metal cutting. These blades consist of a composite material bonded to a metal core. They are designed to grind through metal rather than cut.

- Lower initial cost

- Ideal for thinner materials

- Can create a rougher cut finish

Abrasive blades work well for quick jobs. They may wear out faster than carbide-tipped blades. Here are some key points:

- Best for softer metals.

- Not suitable for thick materials.

- Check compatibility with your circular saw.

Cutting Speed And Power Requirements

Choosing the right size circular saw for sheet metal cutting depends on cutting speed and power. Understanding these factors helps you make informed decisions. Here, we will explore RPM and power sources.

Understanding Rpm

RPM stands for revolutions per minute. It indicates how fast the blade spins. Higher RPM means faster cutting.

Here are some common RPM ranges for sheet metal cutting:

| Blade Type | Typical RPM |

|---|---|

| Steel Cutting Blade | 3,000 – 4,500 |

| Aluminum Cutting Blade | 4,000 – 6,000 |

| Composite Cutting Blade | 3,500 – 5,000 |

Choose a saw with a suitable RPM for your metal type. Too low RPM can cause poor cuts. Too high RPM can damage the material.

Power Source Considerations

Power sources impact cutting speed and efficiency. Circular saws can be corded or cordless.

- Corded Saws: Generally offer more power.

- Cordless Saws: Provide portability and convenience.

Consider the following power ratings:

- Corded: Usually ranges from 10 to 15 amps.

- Cordless: Commonly features 18V to 60V batteries.

Higher power ratings lead to faster cuts. Ensure the power source matches your project needs.

Safety Features And Accessories

Cutting sheet metal requires attention to safety. Circular saws can be dangerous without proper precautions. Using the right safety gear and accessories helps protect you during cutting tasks.

Essential Safety Gear

Wearing the correct safety gear is crucial. Here are the essential items:

- Safety Glasses: Protects your eyes from metal shards.

- Hearing Protection: Reduces noise from the saw.

- Gloves: Shields your hands from sharp edges.

- Dust Mask: Prevents inhalation of metal dust.

- Steel-Toed Boots: Protects your feet from heavy materials.

Useful Cutting Accessories

Using accessories improves safety and efficiency. Consider these useful items:

| Accessory | Purpose |

|---|---|

| Blade Guards | Protects blade when not in use. |

| Work Clamps | Stabilizes the metal sheet during cutting. |

| Cutting Guides | Ensures straight cuts. |

| Lubricants | Reduces friction and heat. |

| Dust Collection System | Keeps your workspace clean. |

Investing in the right accessories enhances your safety. Always prioritize your well-being while cutting sheet metal.

Precision Cutting Techniques

Precision cutting is vital for working with sheet metal. The right tools and methods ensure clean cuts. This section covers essential techniques for achieving precision.

Setting The Correct Depth

Setting the cutting depth is crucial for effective results. Follow these steps:

- Adjust the saw blade to the metal thickness.

- Ensure the blade extends just below the sheet.

- Lock the depth adjustment securely.

Here are some tips:

- A shallow cut prevents blade binding.

- Deep cuts can damage the material.

- Test on scrap metal first.

Guides And Clamps For Straight Cuts

Using guides and clamps enhances cutting accuracy. Consider these tools:

| Tool | Purpose |

|---|---|

| Straight Edge Guide | Ensures a straight cut across the metal. |

| Clamps | Secures the metal to prevent movement. |

| Angle Guide | Helps with angled cuts for precision. |

Follow these steps for using guides:

- Position the guide along the cut line.

- Secure it with clamps to prevent shifting.

- Check alignment before cutting.

Proper use of guides and clamps leads to cleaner cuts. It minimizes mistakes and improves overall quality.

Maintenance Tips For Longevity

Proper maintenance ensures your circular saw lasts longer. Taking care of your saw and its blade can improve performance. Follow these tips for optimal results.

Blade Care

Keeping your blade in good shape is essential. Here are some important tips:

- Clean the Blade: Remove dust and debris after each use.

- Inspect for Damage: Check for nicks or dull edges.

- Sharpen as Needed: Use a sharpening tool to maintain sharpness.

- Store Properly: Keep the blade in a protective case.

Saw Maintenance

Regular maintenance keeps your circular saw functioning well. Follow these steps:

- Check the Power Cord: Ensure it is free from damage.

- Tighten Screws: Regularly check and tighten all screws.

- Lubricate Moving Parts: Use appropriate oil for smoother operation.

- Inspect the Base Plate: Ensure it is flat and clean.

| Maintenance Task | Frequency |

|---|---|

| Clean Blade | After Each Use |

| Inspect for Damage | Weekly |

| Sharpen Blade | Monthly |

| Check Power Cord | Before Each Use |

| Lubricate Parts | Every 6 Months |

Real-world Applications

Understanding the right size circular saw for sheet metal cutting helps in various projects. This tool is essential for both DIY enthusiasts and professionals. Knowing its applications can maximize efficiency and effectiveness.

Diy Projects

Many DIY projects require cutting sheet metal. Here are some common uses:

- Metal Art: Create beautiful sculptures or wall hangings.

- Home Decor: Make custom light fixtures or furniture accents.

- Outdoor Projects: Construct fences, gates, or planters.

For these projects, a circular saw with a blade size of 7-1/4 inches works well. It provides enough power and precision.

Professional Use Cases

In professional settings, circular saws play a vital role. Here are some industries that benefit:

| Industry | Application |

|---|---|

| Construction | Cutting metal sheets for roofs and walls. |

| Manufacturing | Creating parts for machinery and vehicles. |

| HVAC | Shaping ducts and ventilation systems. |

In these cases, a larger saw, like a 10-inch model, is ideal. It handles thicker materials effectively.

Choosing the right size is crucial for safety and efficiency. Using the proper tool can save time and effort in any project.

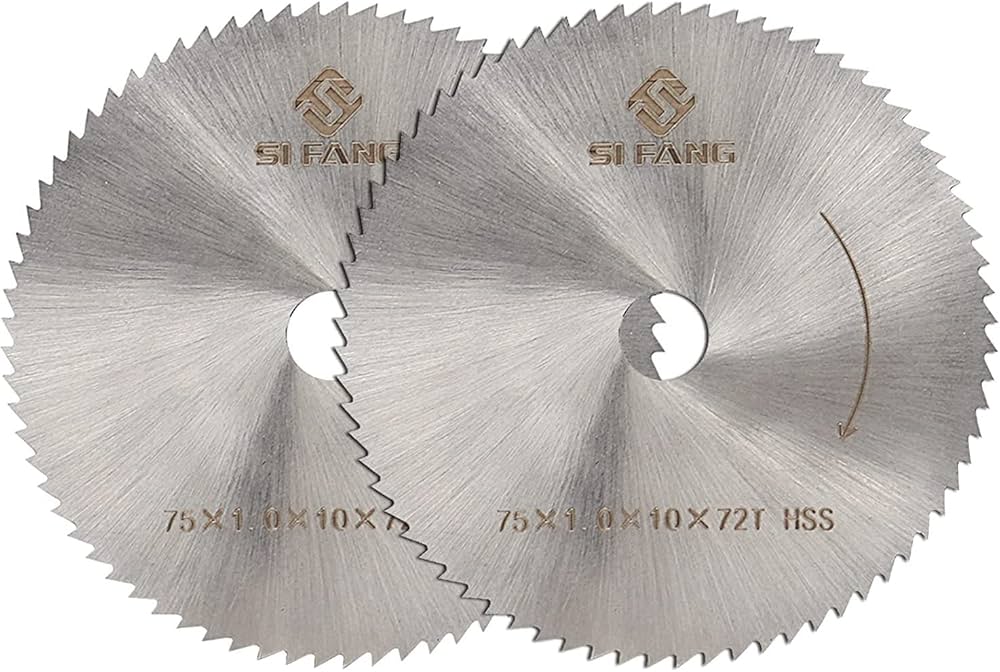

Credit: www.amazon.com

Frequently Asked Questions

- What Is The Best Size For A Circular Saw?

A 7-1/4 inch circular saw is ideal for most sheet metal cutting tasks, providing balance and power.

- Can I Use A Circular Saw For Metal?

Yes, with the right blade designed for metal cutting, a circular saw can efficiently cut sheet metal.

- What Blade Is Best For Cutting Sheet Metal?

A carbide-tipped blade or a metal-cutting blade specifically designed for circular saws works best for sheet metal.

- Is A Cordless Circular Saw Effective For Metal?

A cordless circular saw can be effective, but ensure it has enough power and the right blade for metal.

- How Thick Metal Can A Circular Saw Cut?

Most circular saws can handle sheet metal up to 1/4 inch thick, depending on the blade used. “`

Conclusion

Choosing the right size circular saw for cutting sheet metal is crucial for efficiency and safety. A saw with a blade diameter of 7. 25 inches is ideal for most tasks. Always prioritize quality and performance to achieve clean cuts.

Invest in the right tools, and your projects will benefit greatly.