Ladders are essential tools in construction and maintenance. They ensure safe access in confined spaces like trenches.

Working in trenches poses unique challenges. Safety is a top concern. Choosing the right ladder is crucial to avoid accidents. Trenches can be deep, narrow, and unstable. Each type of ladder serves a different purpose. Some provide stability on uneven surfaces.

Others offer ease of transport and setup. In this post, we’ll explore various ladder options. We’ll discuss their features and best uses. This guide will help you make informed choices. Your safety depends on it. Let’s dive into the types of ladders suitable for trench work.

Types Of Ladders For Trenches

Working in trenches requires the right tools for safety and efficiency. Choosing the correct ladder is crucial. Different trenches need different ladders. Here are the main types of ladders used in trenches:

Extension Ladders

Extension ladders are highly versatile and adjustable. These ladders can extend to various lengths, making them ideal for deep trenches. They are made of strong materials like aluminum or fiberglass.

- Durable: Built to withstand harsh conditions.

- Adjustable: Can be extended to reach different depths.

- Stable: Equipped with non-slip feet for added safety.

Extension ladders are easy to transport and store. They collapse into a compact size. This makes them perfect for professionals who need to move quickly between job sites.

Step Ladders

Step ladders are another common choice for trench work. These ladders are self-supporting. They stand on their own without needing to lean against a wall.

| Feature | Benefit |

|---|---|

| Self-supporting design | Can be used in the middle of a trench. |

| Wide steps | Provide a stable platform for standing. |

| Lightweight | Easy to carry and set up. |

Step ladders are typically made of aluminum or fiberglass. They come in various heights. This makes them suitable for both shallow and moderately deep trenches.

Choosing the right ladder for trench work is essential. It ensures safety and boosts productivity. Consider the depth and conditions of your trench. Then select the ladder that meets your needs best.

Credit: laddersafetyrails.com

Material Considerations

When working in a trench, choosing the right ladder is crucial. The material of the ladder affects its safety and efficiency. Different materials offer various benefits and drawbacks. Here, we will discuss two common types of ladders: aluminum and fiberglass.

Aluminum Ladders

Aluminum ladders are lightweight and easy to carry. They are also resistant to corrosion, making them ideal for outdoor use. The lightness of aluminum makes it easy to transport and position in a trench. This type of ladder is also affordable, which is a big advantage.

Yet, aluminum ladders have some downsides. They conduct electricity, which can be dangerous. Avoid using aluminum ladders near electrical sources. Despite their light weight, they may not be as strong as other materials. Consider the load capacity before use.

Fiberglass Ladders

Fiberglass ladders are non-conductive, making them safe for electrical work. They are also very durable and can withstand harsh conditions. Fiberglass does not corrode or rust, which extends the ladder’s life.

However, fiberglass ladders are heavier than aluminum ones. This can make them harder to move and position in a trench. They are also more expensive. Evaluate if the added safety and durability justify the higher cost and weight.

In summary, both aluminum and fiberglass ladders have unique benefits. Choose based on your specific needs and working conditions.

Safety Features

When using ladders in a trench, safety is critical. The right safety features can prevent accidents and injuries. Let’s look at some important safety features for trench ladders.

Non-slip Treads

Ladders with non-slip treads are essential. These treads provide extra grip. They reduce the risk of slipping. Look for ladders with rubber or textured steps. This ensures better traction, even in wet conditions.

Stabilizing Feet

Stabilizing feet keep the ladder steady. They prevent the ladder from tipping. The feet should be wide and made of durable material. Rubber feet are a good option. They grip the ground well. Some ladders also have adjustable feet. This helps when the trench floor is uneven.

| Feature | Benefit |

|---|---|

| Non-Slip Treads | Reduces the risk of slipping |

| Stabilizing Feet | Prevents tipping and keeps ladder steady |

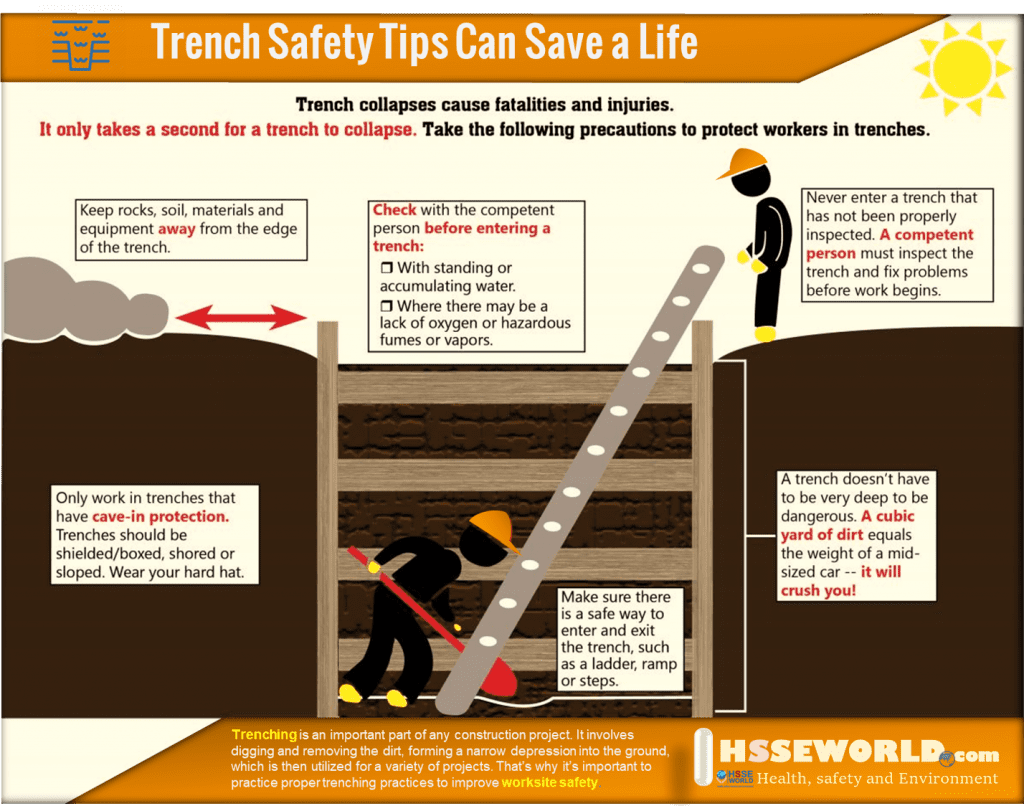

Credit: hsseworld.com

Regulations And Standards

Understanding the regulations and standards for using ladders in a trench is crucial. These guidelines ensure the safety of workers and compliance with legal requirements. Below, we explore the key regulations from OSHA and ANSI standards.

Osha Guidelines

The Occupational Safety and Health Administration (OSHA) provides strict guidelines for ladder use in trenches. According to OSHA, ladders must be used in trenches that are 4 feet deep or more. Here are the key points:

- Ladders should be placed within 25 feet of all workers.

- Ladders must extend at least 3 feet above the trench edge.

- Ensure the ladder is stable and secure before use.

- Inspect the ladder for damage before each use.

Following these OSHA guidelines helps prevent accidents and ensures safety in trench work.

Ansi Standards

The American National Standards Institute (ANSI) also sets standards for ladder safety. These standards complement OSHA guidelines and provide additional safety measures. Key ANSI standards include:

- Use ladders that meet ANSI A14.5 specifications.

- Ensure ladders are free from visible defects.

- Use non-conductive ladders around electrical hazards.

- Follow proper ladder angle and positioning guidelines.

Adhering to ANSI standards ensures high safety levels and reduces the risk of ladder-related incidents in trenches.

By understanding and following these regulations and standards, you can ensure a safe working environment in trench operations.

Proper Ladder Placement

Proper ladder placement in a trench is crucial for safety. Incorrect placement can lead to accidents and injuries. Workers must follow guidelines to ensure safe ladder use in trenches.

Distance From Trench Edge

Place the ladder no more than 24 inches from the trench edge. This distance helps workers to access the ladder easily. It also reduces the risk of the ladder slipping.

According to OSHA guidelines, the ladder must extend three feet above the trench edge. This extension provides a secure handhold for workers entering or exiting the trench.

Angle Of Placement

The ladder should be placed at a 4:1 angle. For every four feet of height, the base should be one foot away from the trench wall. This angle ensures stability and reduces the risk of tipping.

Use a simple table to remember the correct angle:

| Height of Ladder (feet) | Distance from Base (feet) |

|---|---|

| 4 | 1 |

| 8 | 2 |

| 12 | 3 |

Maintaining this angle helps to prevent the ladder from slipping. Always check the angle before use.

Here are some quick tips for proper ladder placement:

- Ensure the ladder is on stable ground.

- Secure the top of the ladder to prevent movement.

- Inspect the ladder for any damage before use.

- Keep the area around the ladder free of debris.

Following these steps helps to ensure the safety of all workers.

Credit: www.wernerco.com

Inspection And Maintenance

Ensuring the safety of ladders used in a trench is crucial. Proper inspection and maintenance help to prevent accidents. Regular checks and upkeep ensure ladders remain in good condition. Below are some essential steps for inspection and maintenance of trench ladders.

Pre-use Checks

- Check for visible damage like cracks, bends, or warping.

- Inspect rungs and side rails for signs of wear or corrosion.

- Ensure all safety labels are readable and intact.

- Verify that locking mechanisms are working properly.

- Ensure ladder feet are stable and non-slip.

Regular Maintenance

Regular maintenance of ladders is essential to extend their lifespan and ensure safety. Here are some maintenance tips:

- Clean the ladder regularly to remove dirt and debris.

- Lubricate moving parts to ensure smooth operation.

- Store ladders in a dry, cool place to avoid corrosion.

- Replace worn-out parts immediately to prevent accidents.

- Conduct detailed inspections monthly or as required by regulations.

By following these steps, you can maintain the safety and functionality of your trench ladders. Regular inspection and maintenance are key to preventing accidents and ensuring a safe working environment.

Frequently Asked Questions

What Type Of Ladder Is Safe For Trench Work?

A fiberglass ladder is safe for trench work. It’s non-conductive and sturdy.

Can You Use An Aluminum Ladder In A Trench?

Yes, but it’s not the best choice. Aluminum ladders conduct electricity.

Are Wooden Ladders Suitable For Trench Work?

Wooden ladders are not ideal. They can rot and break easily.

Why Use A Fiberglass Ladder In A Trench?

Fiberglass ladders are strong and non-conductive. Ideal for safety in trenches.

How Tall Should A Ladder Be For Trench Work?

The ladder should extend at least 3 feet above the trench edge.

Conclusion

Choosing the right ladder for trench work is vital for safety. Always consider the material and height of the ladder. Fiberglass ladders are strong and non-conductive. Aluminum ladders are lightweight but conduct electricity. Extension ladders are great for deep trenches.

Step ladders work well for shallow trenches. Regular inspection ensures the ladder is in good condition. By following these tips, you can work safely and efficiently in trenches. Stay safe, stay informed, and choose wisely. Your safety depends on it.